TaeguTec’s WINSFEED Series: Revolutionizing the Miniature Machining Market

By Ashutosh Arora

As India’s manufacturing landscape advances, the demand for precision machining, particularly in the miniature market, has surged. Industries such as aerospace, medical devices, and electronics are rapidly expanding, emphasizing the need for reliable, high-quality tooling capable of operating in compact spaces. To meet this demand, TaeguTec has introduced the technologically advanced WINSFEED series, specifically the WIN-I-GROOVE line, which has quickly established itself as a game-changer in the Indian market.

Miniature machining poses unique challenges, particularly in internal grooving for small diameters. Conventional tooling often fails to deliver the precision required, leading to higher operational costs and production delays. TaeguTec’s WINSFEED series, particularly the WIN-I-GROOVE line, addresses these challenges with innovative design and engineering, delivering high performance in confined spaces.

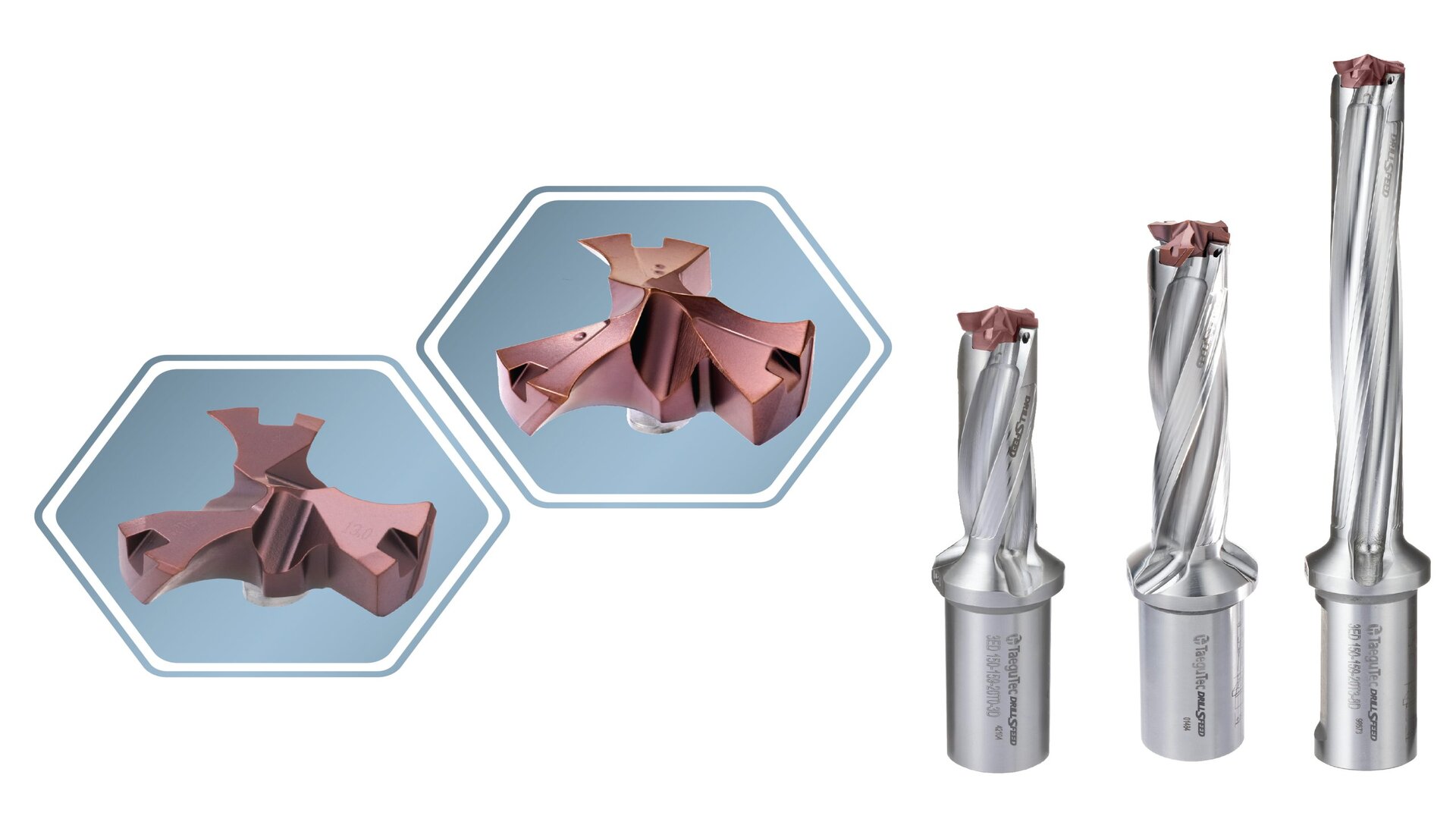

Designed to groove within 6-8 mm small inner diameters, the WIN-I-GROOVE line’s small bore internal grooving inserts ensure precision and efficiency. This capability not only enhances machining performance but also offers a cost-effective alternative to expensive solid carbide tools, making it a valuable solution for miniature components.

At the heart of the WIN-I-GROOVE line is its innovative inclined clamping system. Featuring a wide contact surface for both the TMIR/L inserts and TMIHR/L holders, this design ensures stronger clamping, improving machining stability, resulting in better surface finishes and longer tool life. This robust clamping system is crucial in miniature machining, where any instability can compromise the final product.

Additionally, the inclined clamping structure enhances chip evacuation, a common challenge in miniature machining. Efficient chip removal minimizes the risk of tool damage and workpiece defects, enhancing productivity and ensuring smooth operations.

The versatility of the WIN-I-GROOVE line further strengthens its position in the miniature machining market. With a variety of holders designed for different machining tasks, TaeguTec offers steel holders for 2xD depth machining and carbide brazed holders capable of achieving deep internal grooving up to 4xD. This flexibility makes the WINSFEED series suitable for a wide range of applications across industries.

Another standout feature is the integrated internal coolant system, which directs coolant precisely to the cutting edge. This reduces heat build-up, facilitates chip evacuation, and ultimately extends tool life, making it a valuable feature in a market where minimizing downtime and tool replacement is critical to profitability.

Since its launch, TaeguTec’s WINSFEED series has rapidly gained the trust of India’s miniature machining market. Manufacturers from various industries recognize the value of the WIN-I-GROOVE line, not only for its ability to meet the stringent demands of miniature machining but also for its contribution to reducing operational costs and enhancing productivity.

By addressing the challenges of small-scale machining with advanced design and engineering, TaeguTec continues to drive innovation in India’s precision machining market, setting new standards for performance and efficiency.