- Eventas

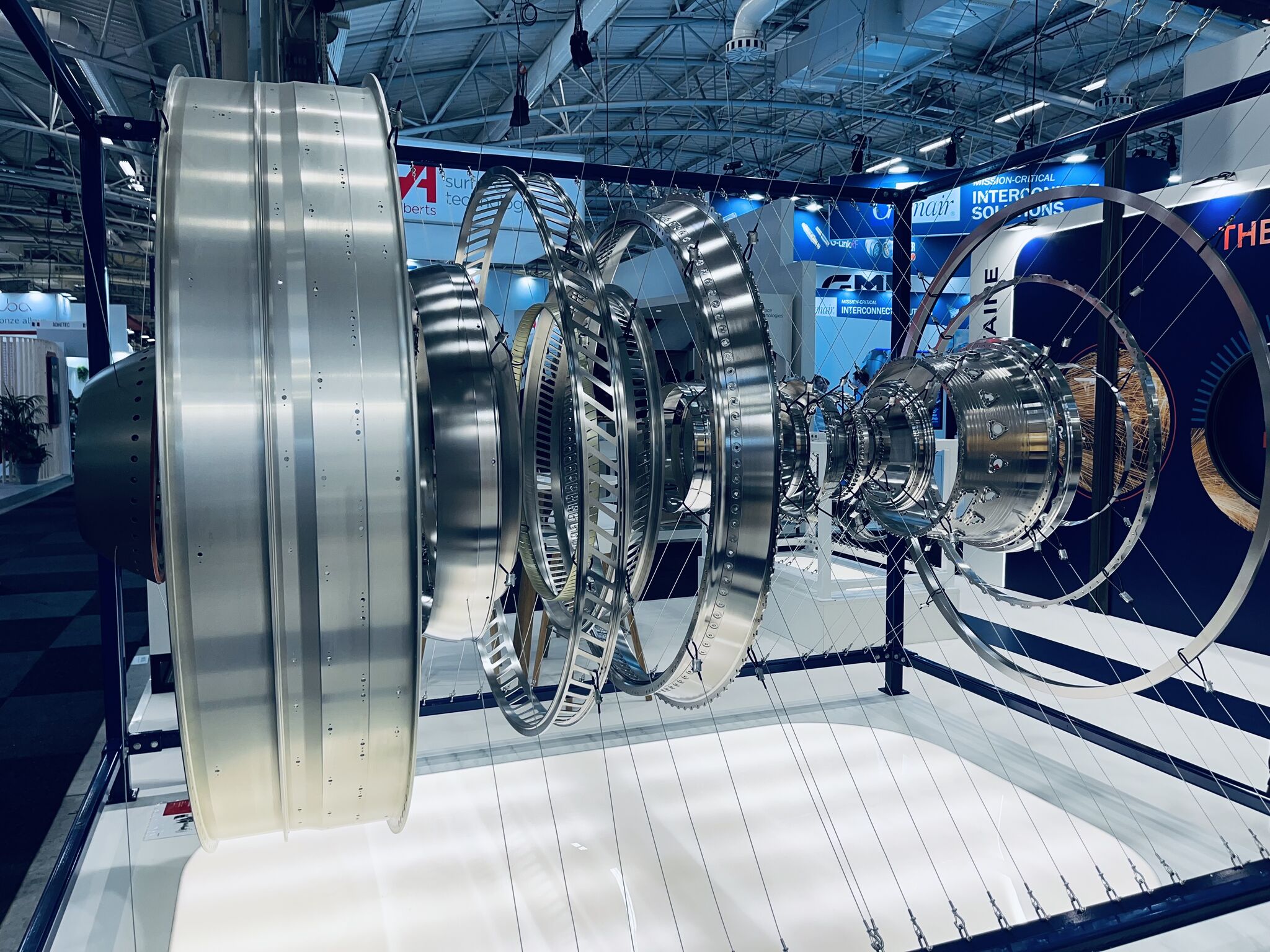

Aerospace Focus Intensifies for OPEN MIND at the Paris Air Show 2025

Last week, the International Paris Air Show once again proved why it’s the most important event in the aerospace calendar. With footfall described as immense, the atmosphere was electric — a clear sign that the aerospace sector is not just back, but booming. And while OPEN MIND Technologies…

MTDCNCLast viewed

MTDCNCLast viewed Standardization, high-quality machine investment creates long-term scalable production for young Alabama company

Smith & Co. chose to invest heavily in its people, processes and solely HERMLE equipment, garnering lights-out manufacturing work Birmingham, AL (Oct. 15, 2024) – Robert and Dell Smith started in the manufacturing industry as kids, working with their father at his part-time machine shop…

MTDCNCLast viewed

MTDCNCLast viewed

Home

Popular

01:54

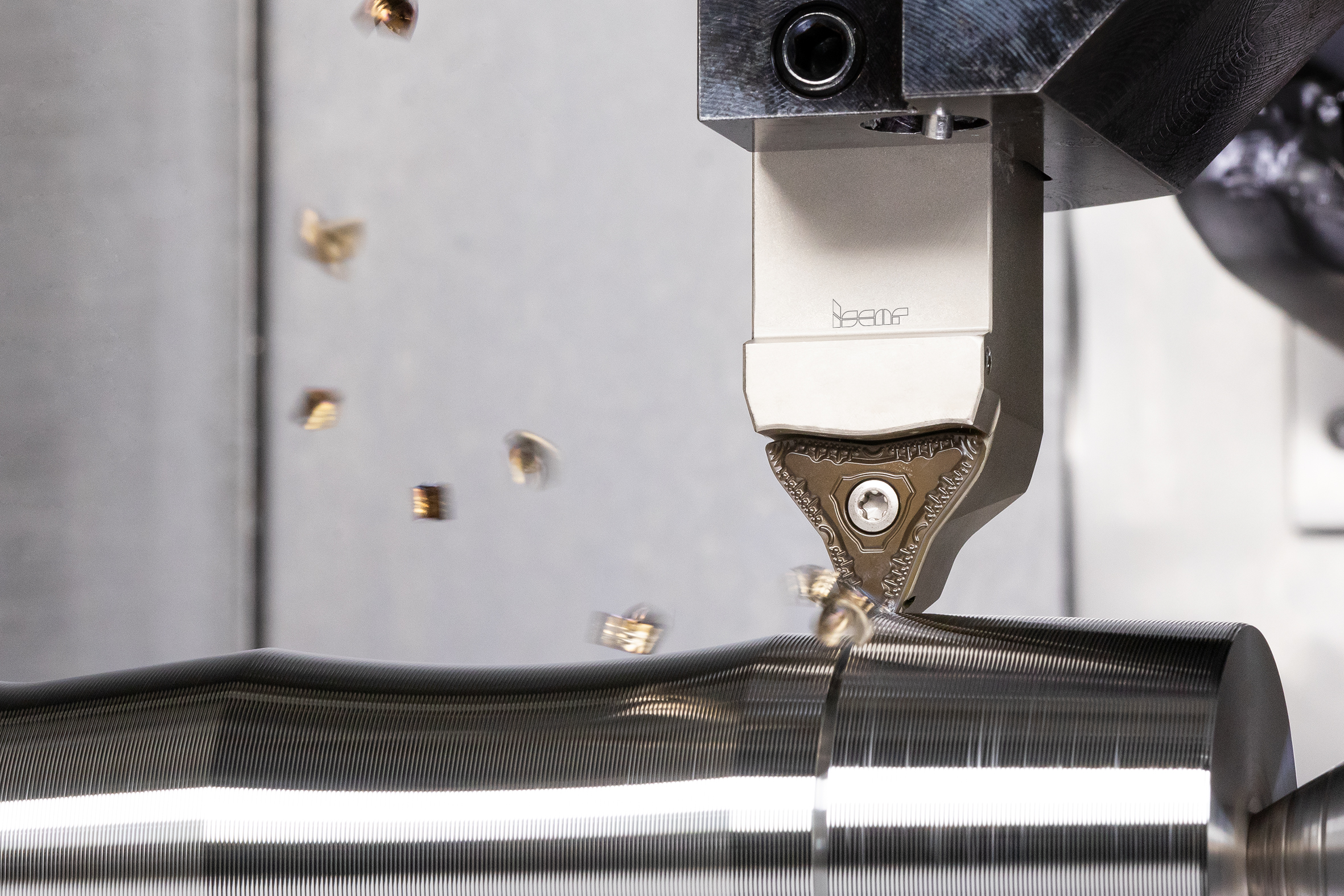

What does 75 kilonewtons of clamping force look like?

Emuge-Franken’s vise grips parts rock-solid with zero prep. No dovetails, no dimpling, no special programming needed — it holds, forms, and stays locked through every cutting direction. If you want to take full advantage of your machine without ever worrying about your part coming loose, this video’s for you! Join MTDCNC’s Arthur Field and Emuge-Franken’s David Jones to learn more.

MTDCNCLast viewed

MTDCNCLast viewed

04:12

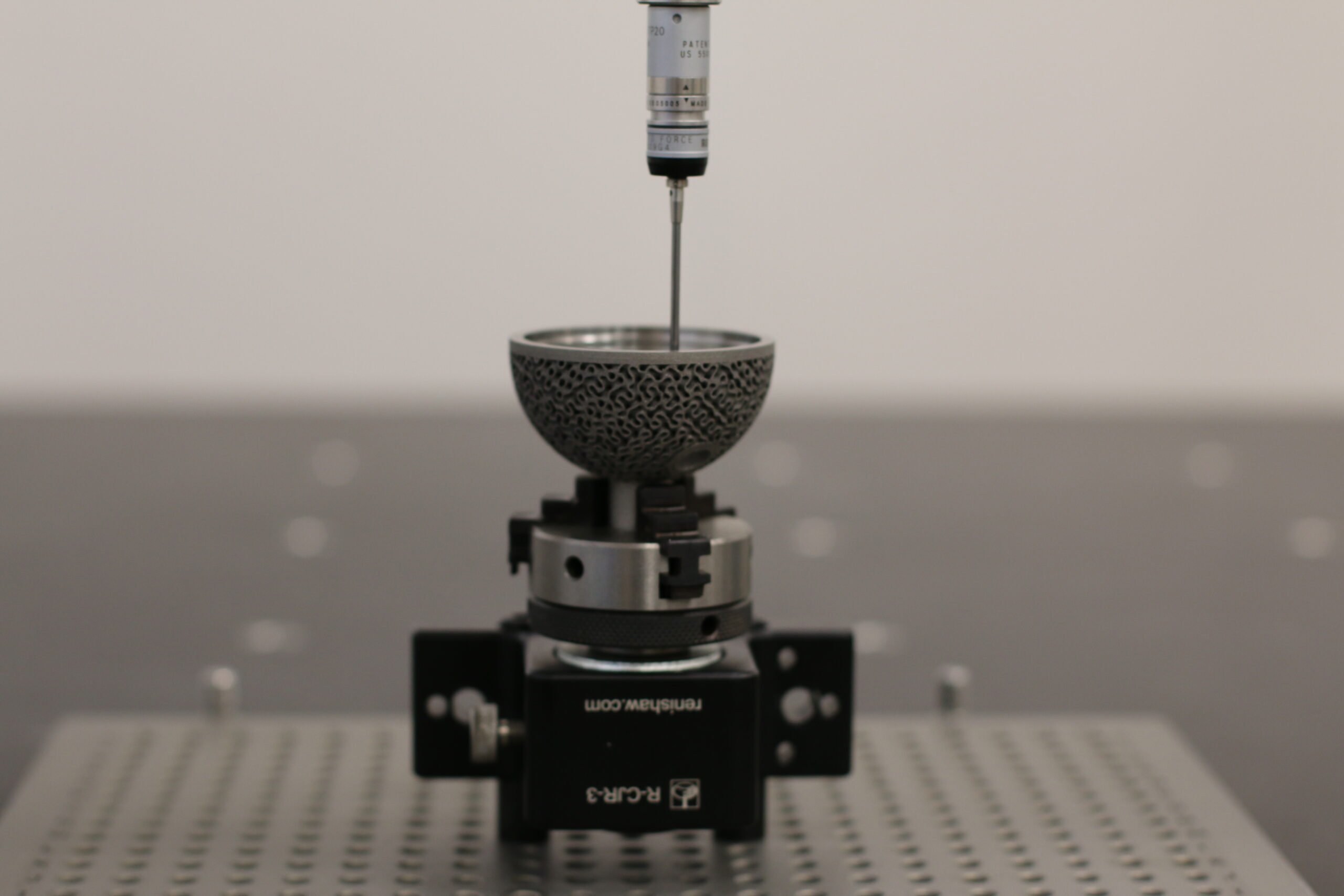

How did this software transform Fairview Machine?

What used to take five or six different software is now done in one clean workflow. Nick Yeager of Fairview Machine shares how 1Factory transformed their inspection process with everything from real-time CMM data uploads to instant AS9102 reports. No more paper stacks, no more manual transfers. Just smooth, seconds-fast visibility for every operator! Tune in with MTDCNC’s Meaghan Ziemba and see why Nick says he’d never go back. Learn more at www.1factory.com.

MTDCNCLast viewed

MTDCNCLast viewed

02:36

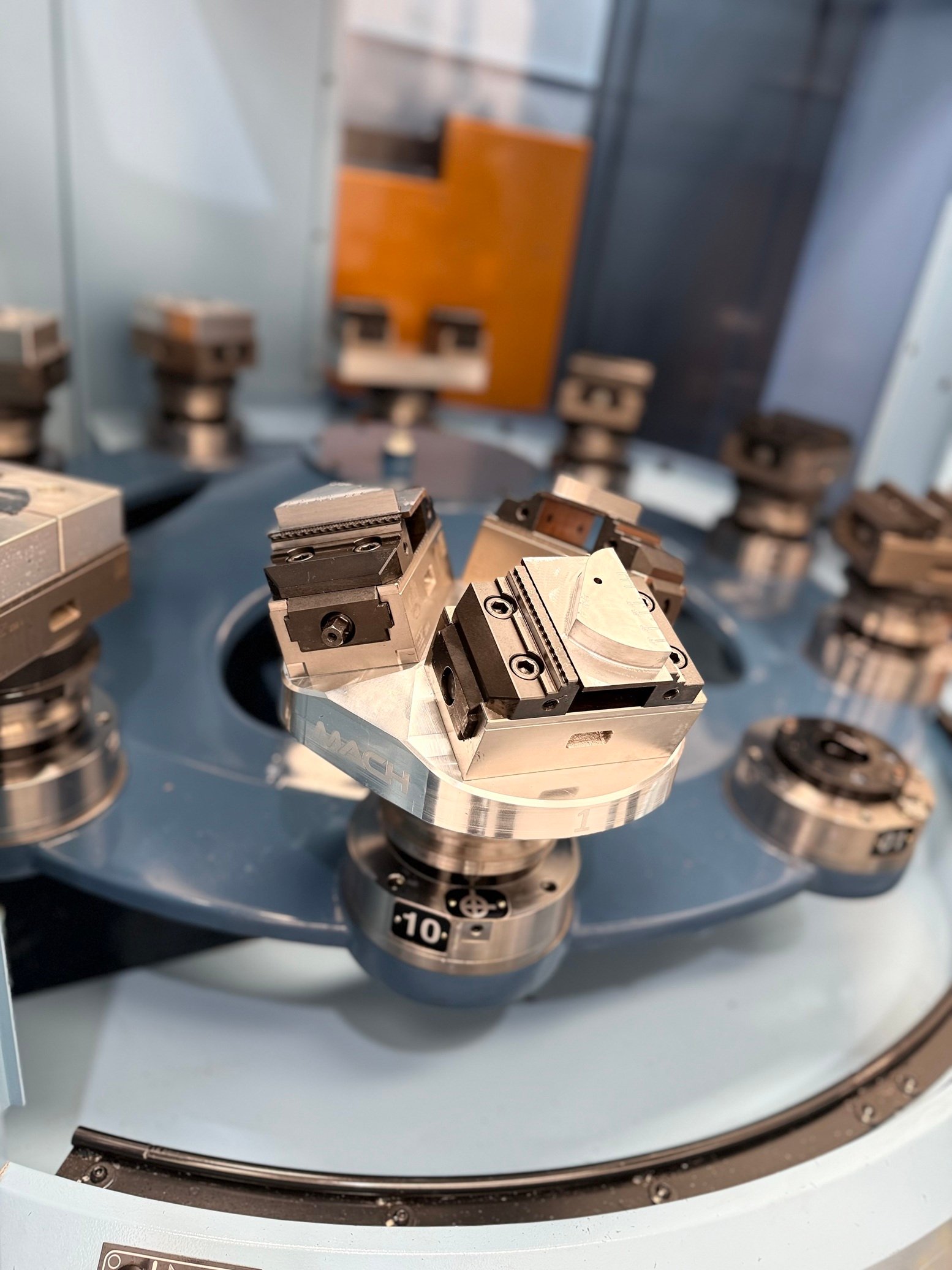

Automation starts at the workholding…

Emuge-Franken’s vices are designed with pickup locations for grippers, making integration into automated workflows seamless. From step files to base plates to programming support, they provide everything shops need to go from table to spindle with ease. Tune in with MTDCNC’s Arthur Field and Emuge-Franken’s David Jones to see how they simplify automation from start to finish.

MTDCNCLast viewed

MTDCNCLast viewed

04:07

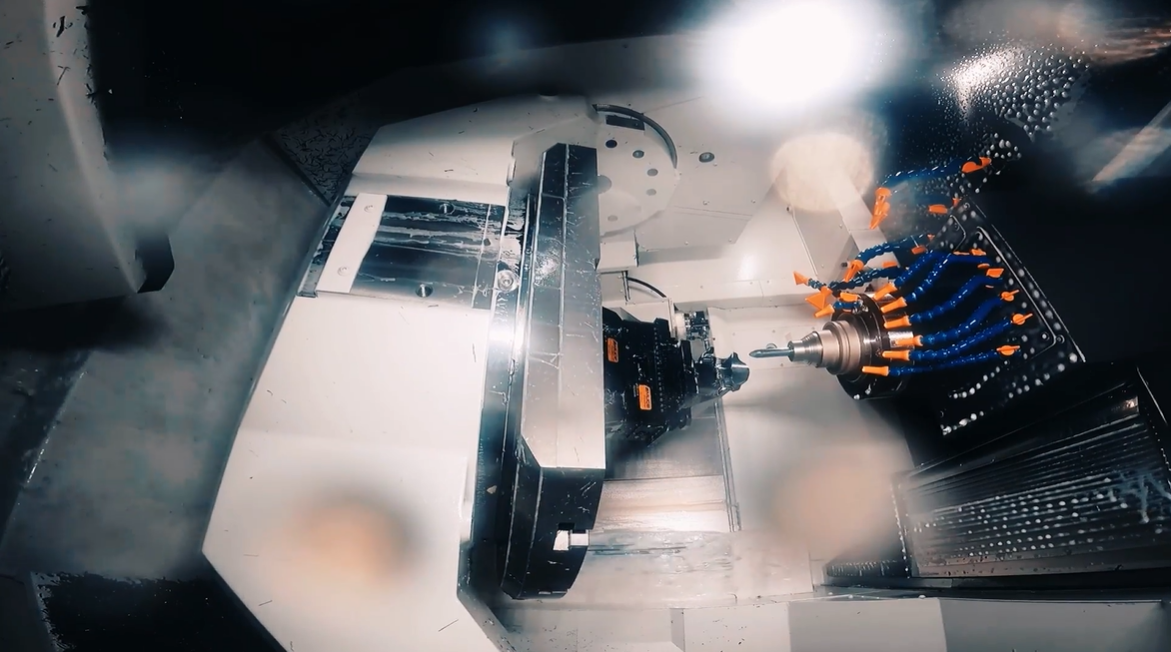

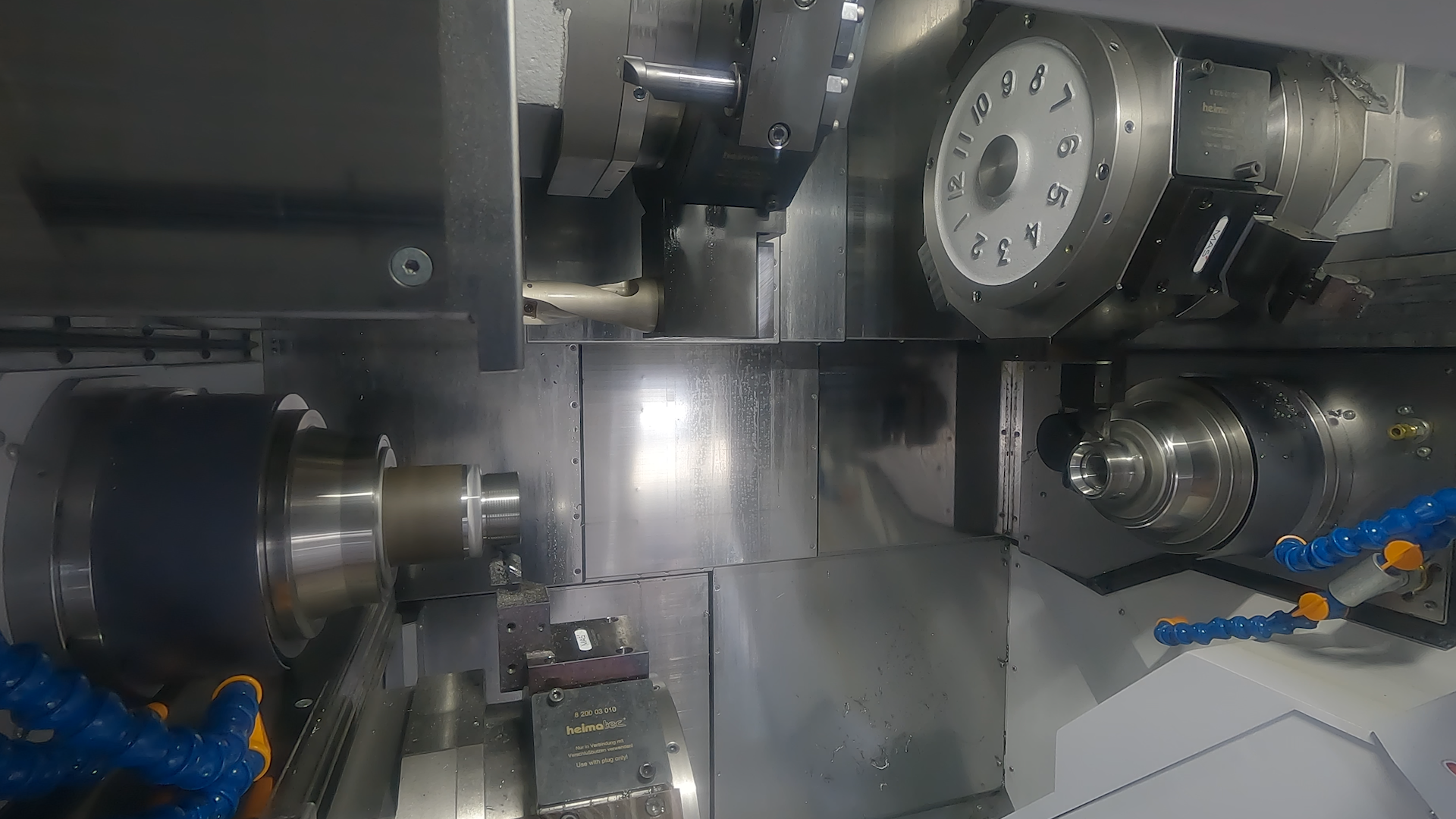

Citizen’s brand-new lathe brings serious muscle to multi-turret performance!

Do you want to keep precision high and downtime low? Citizen’s ABX80THY delivers with three 12-station turrets, upgraded 18 kW spindle power, and enlarged 32mm ball screws for extra rigidity and stability during heavy cutting. The new FANUC 31i touchscreen control streamlines operation, while spindle-sensing technology monitors bearing health and detects runout issues before they become downtime. Tune in with MTDCNC’s Tom Skubala and Citizen Machinery’s Chris Downham to learn how this machine can help you hit those tolerances every time!

Tom SkubalaLast viewed

Tom SkubalaLast viewed

Eventeu

Lyndsey Vickers recently visited SPINNER Bulgaria Ltd. — here’s what she thought

A couple of weeks ago, Lyndsey Vickers spent time at SPINNER Bulgaria Ltd., and her reflections are really worth sharing. She was struck by the warmth of the people and the culture of continuous improvement across all facilities. From her visits to several sites, it’s clear that SPINNER is building on strong internal communication, consistent branding, and a genuine commitment to learning and evolving. (Though which facility is the most state-of-the-art? Lyndsey wouldn’t say—Axel Spinner might not be happy! 🤭) 📋 One highlight was their employee recommendation system, where ideas for both personal and technical improvements are truly heard and

MTDCNCLast viewed

MTDCNCLast viewed

01:02:53

MTDCNC Uncut: From sausages to smart manufacturing

Ever wondered what life is really like behind the scenes in manufacturing? In this episode of MTDCNC Uncut, Lyndsey Vickers, Paul Jones, Joe Reynolds, and Tom Skubala share everything from globe-trotting factory visits to the quirks and challenges of running high-tech shops. Hear about the extreme “sausage incident,” plus how smaller companies are using automation and smart scheduling to outpace the big brands in the race for talent. Tune in for a mix of industry insights, travel stories, and the kind of candid conversations you won’t hear anywhere else!

MTDCNCLast viewed

MTDCNCLast viewed Promotions

Discover the latest special offers and featured products from leading manufacturers and suppliers.

17 July 2025

BROTHER S700Xd1 *NOW EX STOCK* from Whitehouse Machine Tools

SPEEDIO’s bestselling model has further expanded the applicable range. Reduce your costs, improve throughput and cut out the waste by investing in a popular BROTHER machining centre. This ex stock model offers; Travels X:700mm Y:400mm Z:300mm 28-tool magazine High acceleration Z-axis Max. 2.2G Spindle start/stop time 0.15S or less Higher machine rigidity and minimal vibration 7 MPa Coolant Through Spindle (CTS) (optional)

View Product

17 July 2025

Biglia B 620 YS sub spindle turning centre

Now available from stock at Whitehouse machine tools. The new B620 represents the “state of the art” of multifunction turning centers. The modular concept and the high versatile options provide a wide spectrum of machining possibilities ranging from universal turning to complete machining of complex parts thanks to the CNC automatic tailstock, second spindle, rotary tools, spindle C-axis and Y-axis. The B620 is available in five versions with bar capacity of 51 or 80 mm.Il B620 è disponibile in 5 versioni con passaggio barra 51 mm e 80 mm. Rigid cast-iron machine bedPowerful synchronous integral spindle motors15 position Biglia servo

View Product

16 July 2025

BROTHER M200X3 5 axis machining centre with turning *AVAILABLE EX STOCK*

The compact multi-tasking machines, equipped with turning and tilt axes, enable turning and machining processes through one-time chucking. An incredibly fast and efficient method of manufacturing multi face parts. One of a kind, this machine is compact, very economical to run, universal and now ex stock. Contact Whitehouse machine tools to talk to them about the possibilities of a machine like this. With manufacturers wanting to reduce cycle times by one-hit machining, this machine is ideal.

View Product

8 July 2025

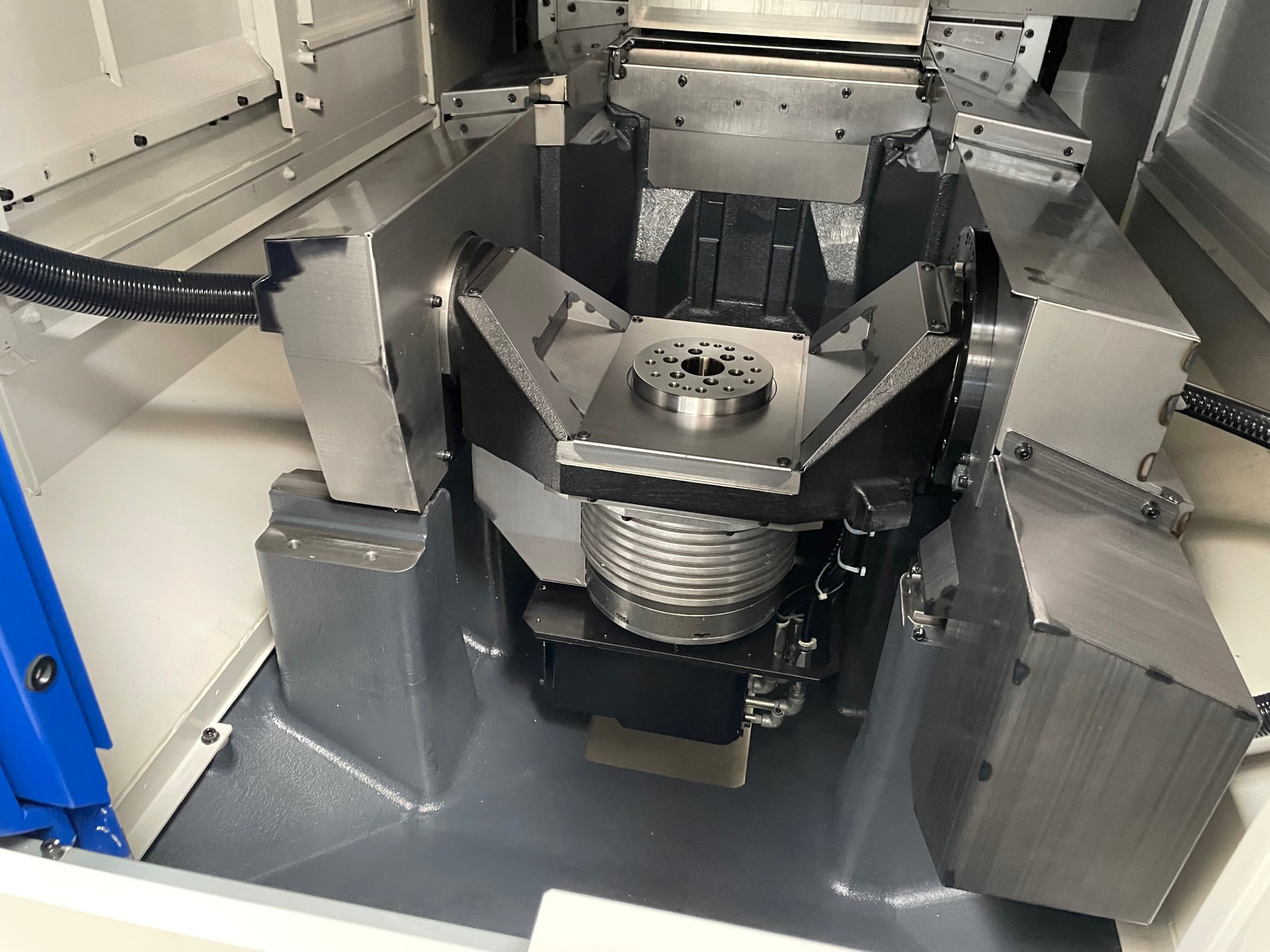

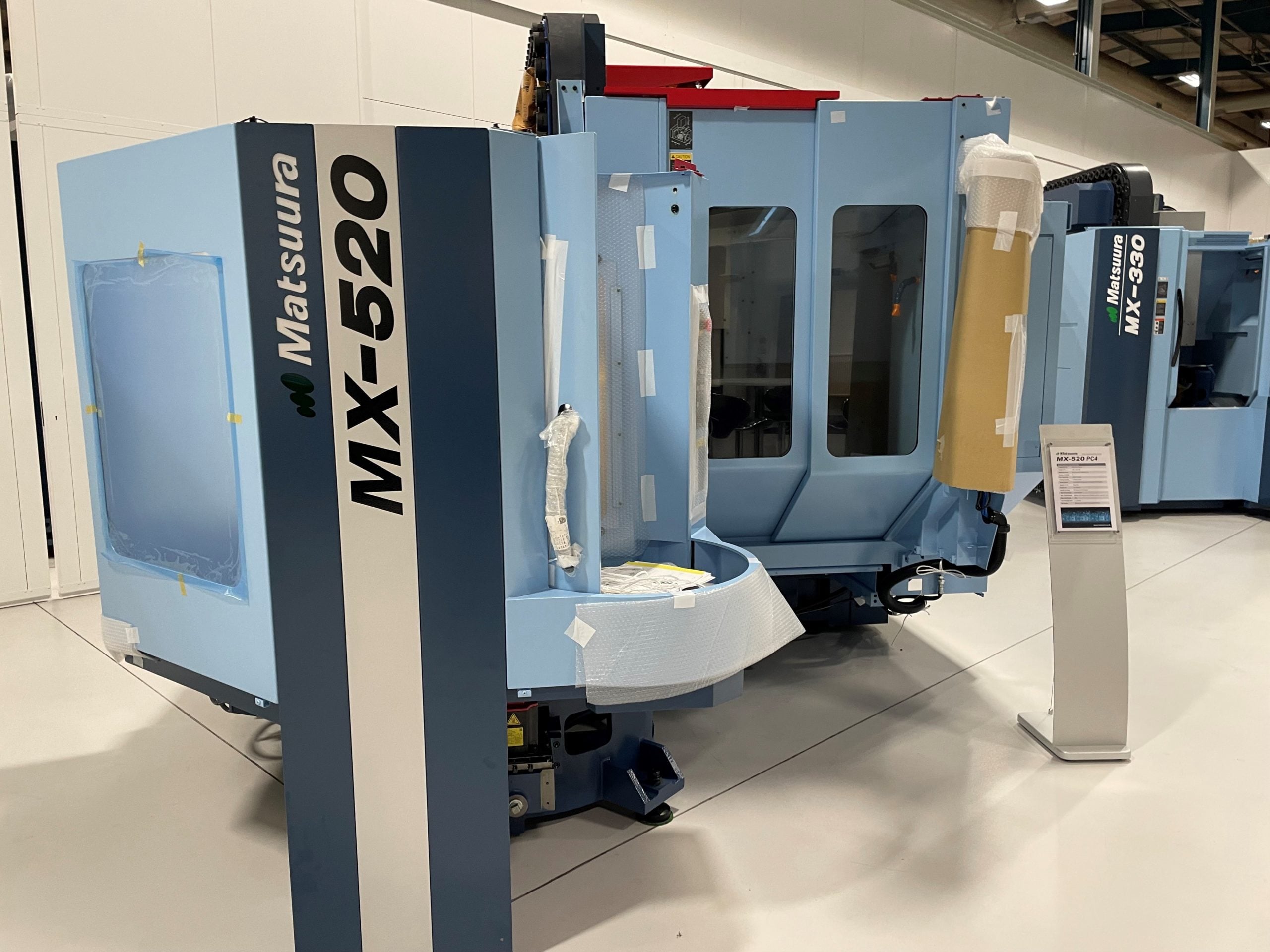

Matsuura MX 520 4 pc, available from stock

MACHINE EX STOCK COALVILLE 2017 saw the launch of the MX-520 PC4 – a Matsuura designed 4 pallet auto-changer system integrated into the MX-520 by our own design house in Fukui Japan, delivering an effective entry level and highly productive introduction to Matsuura 5 axis automation for investing companies. Launched to much acclaim globally in 2010, the MX-520 is a single table 5 axis machine tool primarily aimed at owner operator and SME companies making the transition from 3 to 5 axis operations – although installations to date show that established users of Matsuura MAM72 products are also investing in

View Product

8 July 2025

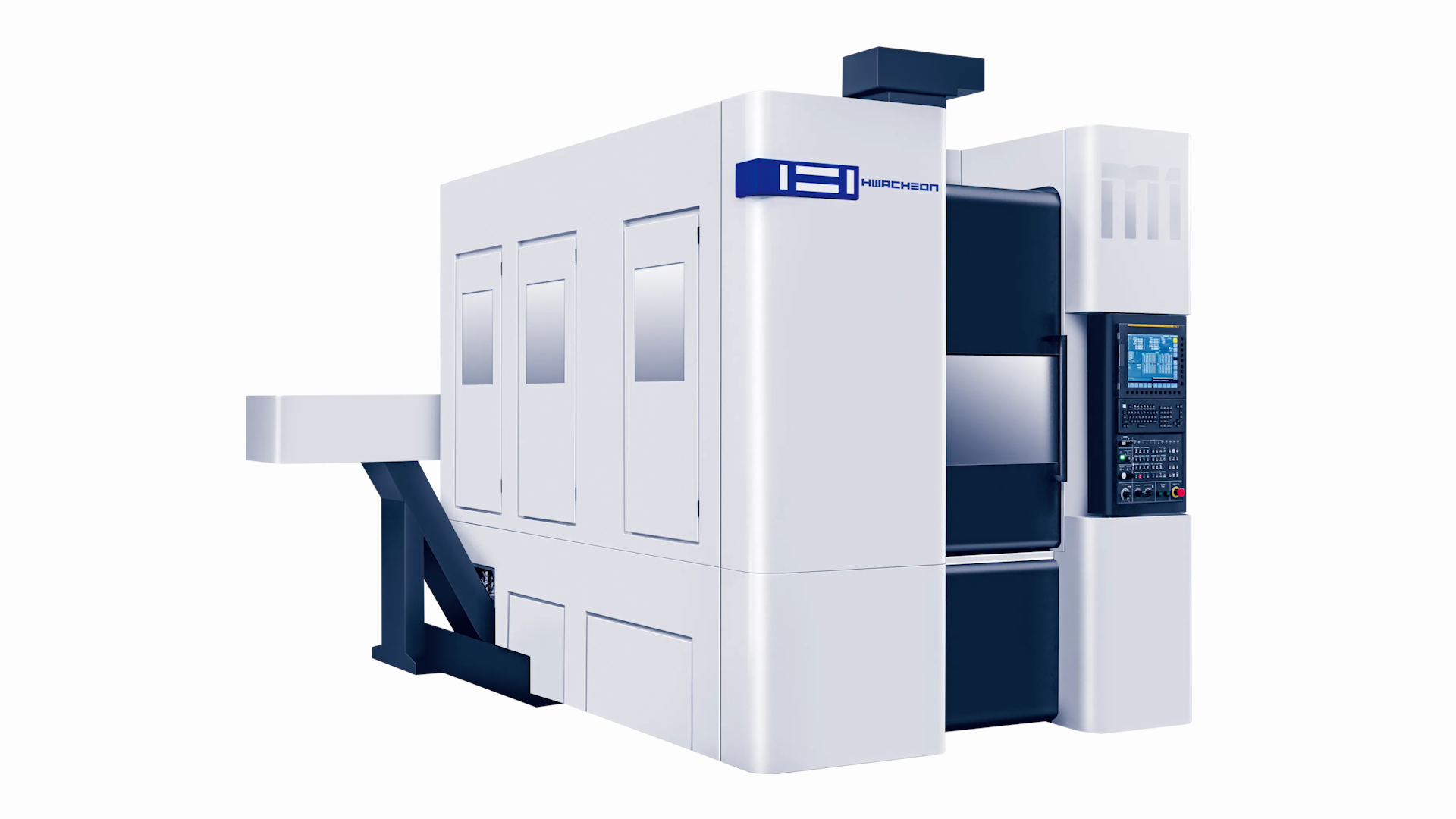

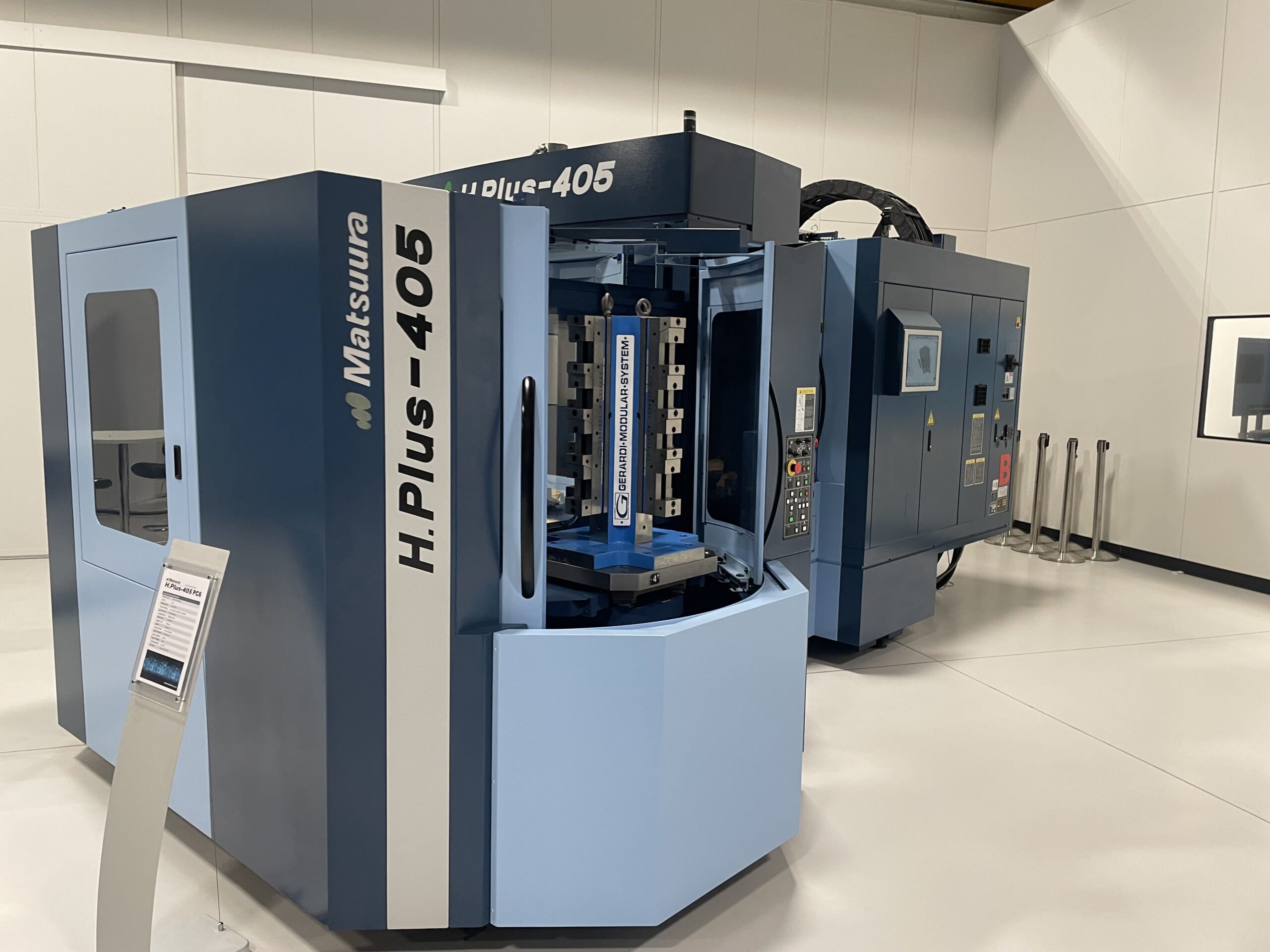

Matsuura H.Plus-405 available from stock

Possessing a 500mm2 pallet, the BT40 Matsuura H.Plus-405 possesses and extols all the productivity enhancing virtues of the H.Plus Series of high quality horizontals. The capacity of this 500mm2 machine belies its small footprint – making it a firm favourite in high volume production environments where floor space is at a premium. Travel: X / Y / Z mm 660 / 660 / 660 Travel: B Axis deg 360 Number of Pallets 2 Standard. 6 / 10 / 17 / 24 / FMS Options Working Surface mm 500 x 500 Max Work Size mm Ø700 x H850 Loading Capacity Per Pallet kg 400 Spindle Speed min-1 12,000:

View Product

What We Do

Your partner for marketing, media, and events in manufacturing.

FactoryNOW

The platform for manufacturers & machine shops to get seen!

FactoryNOW helps manufacturers, machine shops, and industry suppliers showcase their expertise, share their latest news, and reach thousands of engaged professionals worldwide.

Join a growing community dedicated to innovation, connection, and visibility in the manufacturing sector.

Featured Members

FactoryNow Latest

Podcast

Here at MTDCNC, you’ll find a collection of top-notch podcasts featuring discussions and insights from the manufacturing market.

uk

NEW PODCAST: Steve Finn on 2025 – Insights from DMG MORI UK

As 2025 comes to a close, join Steve Finn in conversation with Paul as they share their candid insights on the current state of UK manufacturing. In this in-depth discussion, they cover the industries that are growing and healthy, as well as the challenges many manufacturers continue to face in today’s dynamic environment. In this episode, you’ll hear about: Steve Finn brings decades of experience in precision engineering and manufacturing, providing a unique perspective on how businesses can navigate uncertainty and find opportunities for growth. Whether you’re a manufacturer, engineer, or simply passionate about advanced manufacturing technology, this conversation offers

EP232

What’s the difference between a supplier and a partner?

They don’t just sell a machine and drop it on your shop floor — Starrag runs the entire journey as a full project. In this MTDCNC podcast, Arthur Field sits down with Udo and John of Starrag to unpack how the company delivers almost 24/7 cross-continental project management, structured kick-off meetings, and deep technical support. With around 70% of their North American business in defence and ITAR and over 70 machines supporting programs like the F-35, Starrag brings the engineering strength to handle everything from tooling and turnkey programming to massive foundations. Tune in to learn how Starrag becomes a

EP231

The only oil-mist system that recovers your cutting fluid?!

What if your oil-mist system didn’t just trap oil — but actually separated it and sent it back to your machine? In this podcast, MTDCNC’s Paul Jones sits down with Brad Eicher of 3Nine, the company using centrifugal disk-stack technology born from the milk-processing industry to achieve 99.9% separation down to one micron. The result? Customers recover 50 to 200 millilitres of cutting fluid per hour and often save two to four barrels a year, with HEPA filters lasting up to 18,000 hours. With over 18,000 units installed and a completely different approach from traditional multi-filter systems, 3Nine is proving

UK Manufacturing: MTD Magazine, November Edition!

Listen to some of the best stories of the November 2025 edition of the MTD magazine. This edition’s theme is UK manufacturing with a technology focus on software! Read the full magazine here – https://mtdcnc.com/digital/november-2025 If you’re seeking unparalleled insights into the world of machining and manufacturing, look no further than MTD Magazine. We offer distinctive content that sets us apart. Our magazine is not only a compelling read but also a captivating listen. Explore our articles, or tune in to our audiobook for a comprehensive experience.

EP261

SME Focus Episode 261: Charlie Allen, Lead Project Manager – Automate BEST

SME Focus is the programme showcasing our brilliant SMEs. For manufacturers, by manufacturers. The weekly show was founded by Chris Greenough. Chris has championed the British manufacturing sector for more than two decades, particularly SMEs, and we are delighted that he is hosting this innovative programme brought to you by MTDCNC. The week’s show features PLUS Automation’s Mark Weymouth as he interviews Charlie Allen.

EP230

They’re taking global power to the Americas!

What does it take to introduce a globally recognised manufacturing powerhouse to the U.S. market? MTDCNC’s Arthur Field sits down with industry veterans Andy and Armando from LK Machinery to talk bold ideas, brand-building, and the culture that’s driving their success. From 20,000-ton Giga Press installations to powerhouse partnerships with industry leaders like Rego-Fix, this conversation dives into the innovation and ambition shaping LK Machinery’s journey across the Americas. Tune in for real talk, big machines, and even bigger challenges!