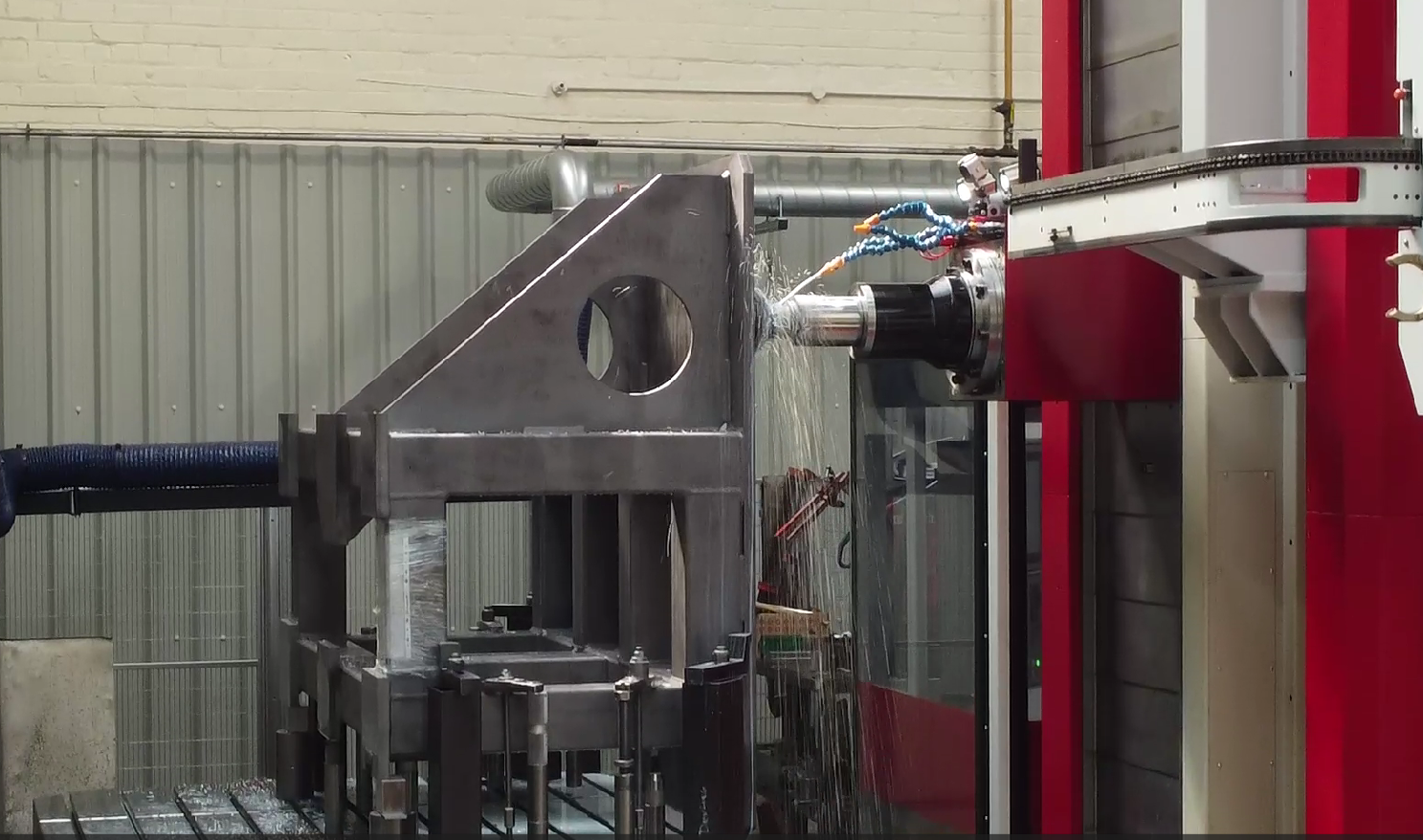

FAT, part of the Haco Group, is well established in its’ production of CNC lathes and special purpose machine tools. Founded over 100 years ago and with its’ own comprehensive machine / assembly shops and sheet metal/paint sections, FAT produces flat-bed and slant-bed lathes, ranging from Ø315mm ~ Ø1400mm chuck size as standard, with extra heavy duty 4–shear models for parts up to 140 tons in weight and over 20M long also available.

With continuous innovations and improved options each year added each year to FAT Haco’s portfolio of lathes, it’s certainly worth the investment.

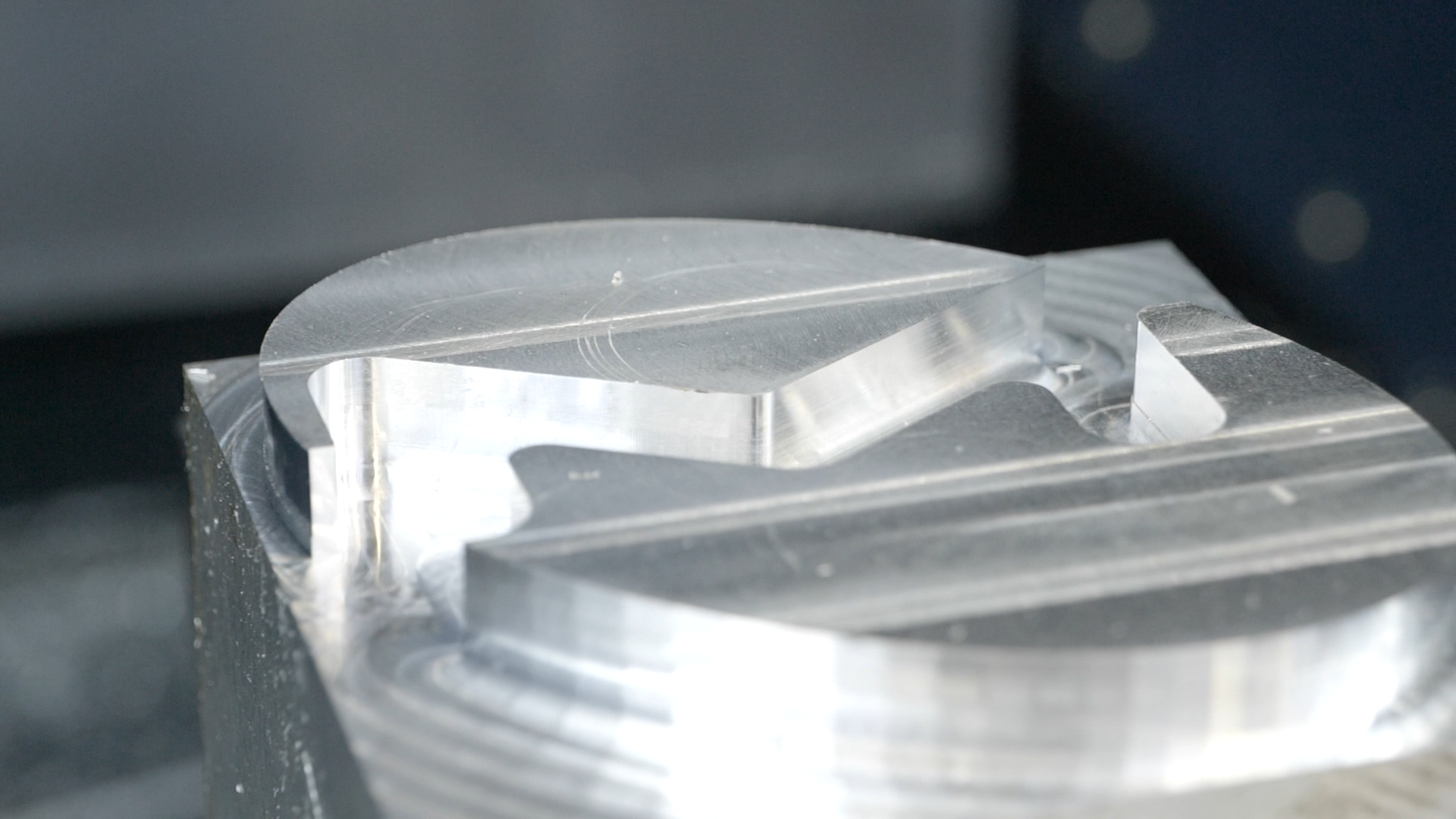

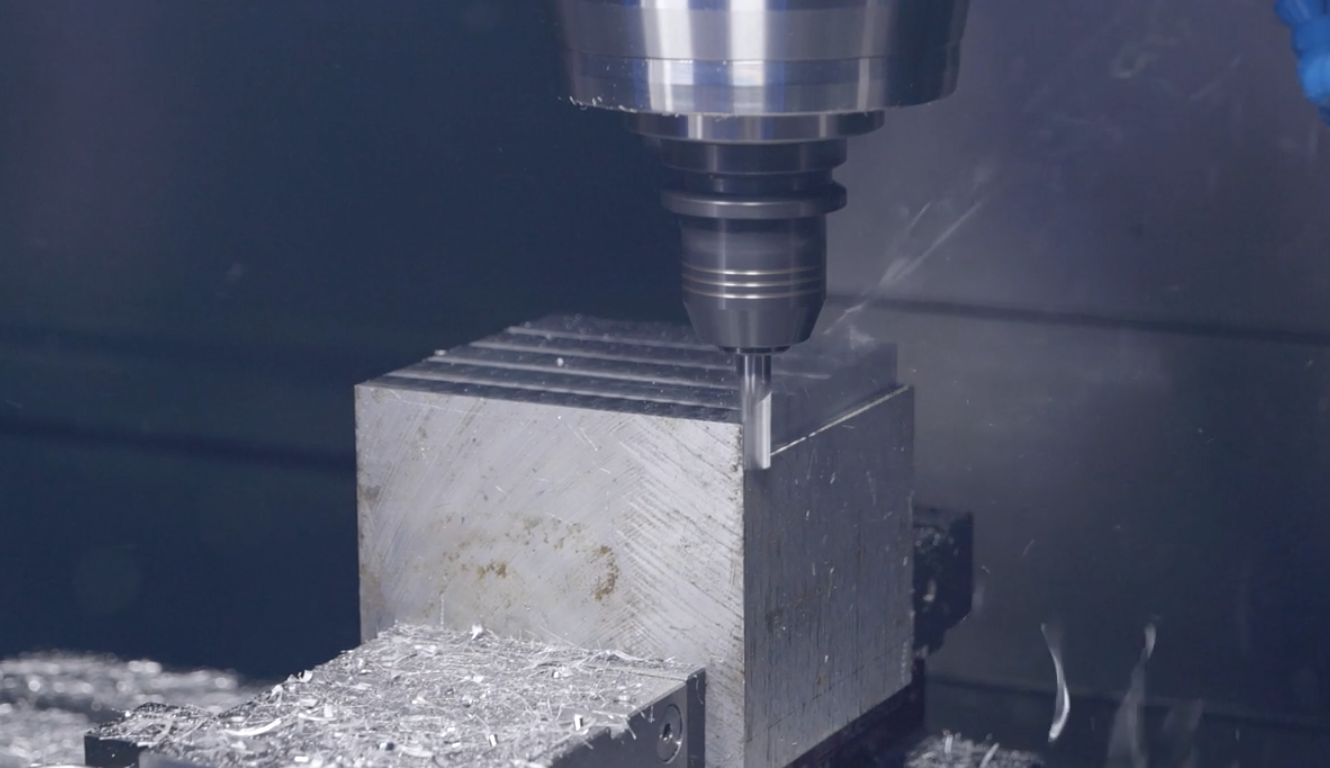

The newest innovation is the impressive TUR SMN range which are high precision and high-quality lathes with exceptional stability and with a high level of equipment included:

– Siemens CNC system: Sinumerik 840D SL with Shop Turn

– Larger Ø140mm spindle bore as standard

– Dual headstock available for long shaft work

– Improved swarf evacuation and coolant system

– Choice of chuck sizes, steadies and tooling arrangements

– 15” touch display screen

– Absolute encoders

Easy programming with the Siemens840D SL control allows manufacturers to work manually, semi-automatic or full CNC. Alternative CNC control systems are available.

Furthermore, some models can be equipped with an additional simplified control panel consisting of push buttons and a joystick, more in line with teaching and manually operated lathes.

For more information on the HACO range visit – www.leadercnc.co.uk or alternatively follow us on our social media channels below.

Linkedin – www.linkedin.com/company/leader-cnc-technologies

Facebook – www.facebook.com/Leader-CNC-Technologies

Twitter – www.twitter.com/LeaderCNCTech