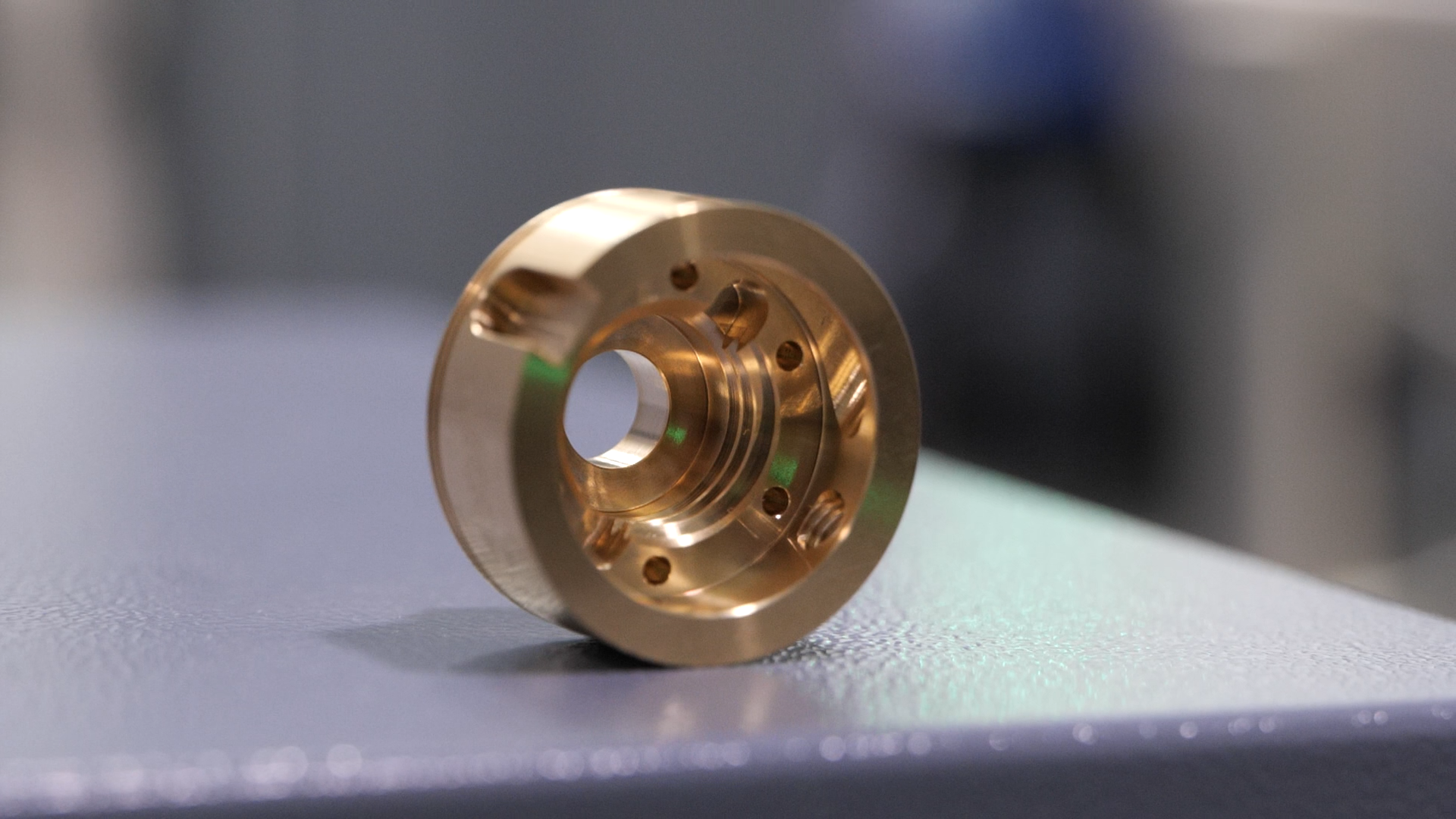

Sliding head is faster, it delivers greater precision, with far more control..

Renishaw’s Miskin site in Wales has undergone a transformation that is nothing short of remarkable. What was once a process plagued by long setup times, extended cycle times, and constant operator intervention to maintain process control has now been turned on its head — all thanks to a new approach built around Star sliding head lathes.

From VMCs to Sliding Head Lathes

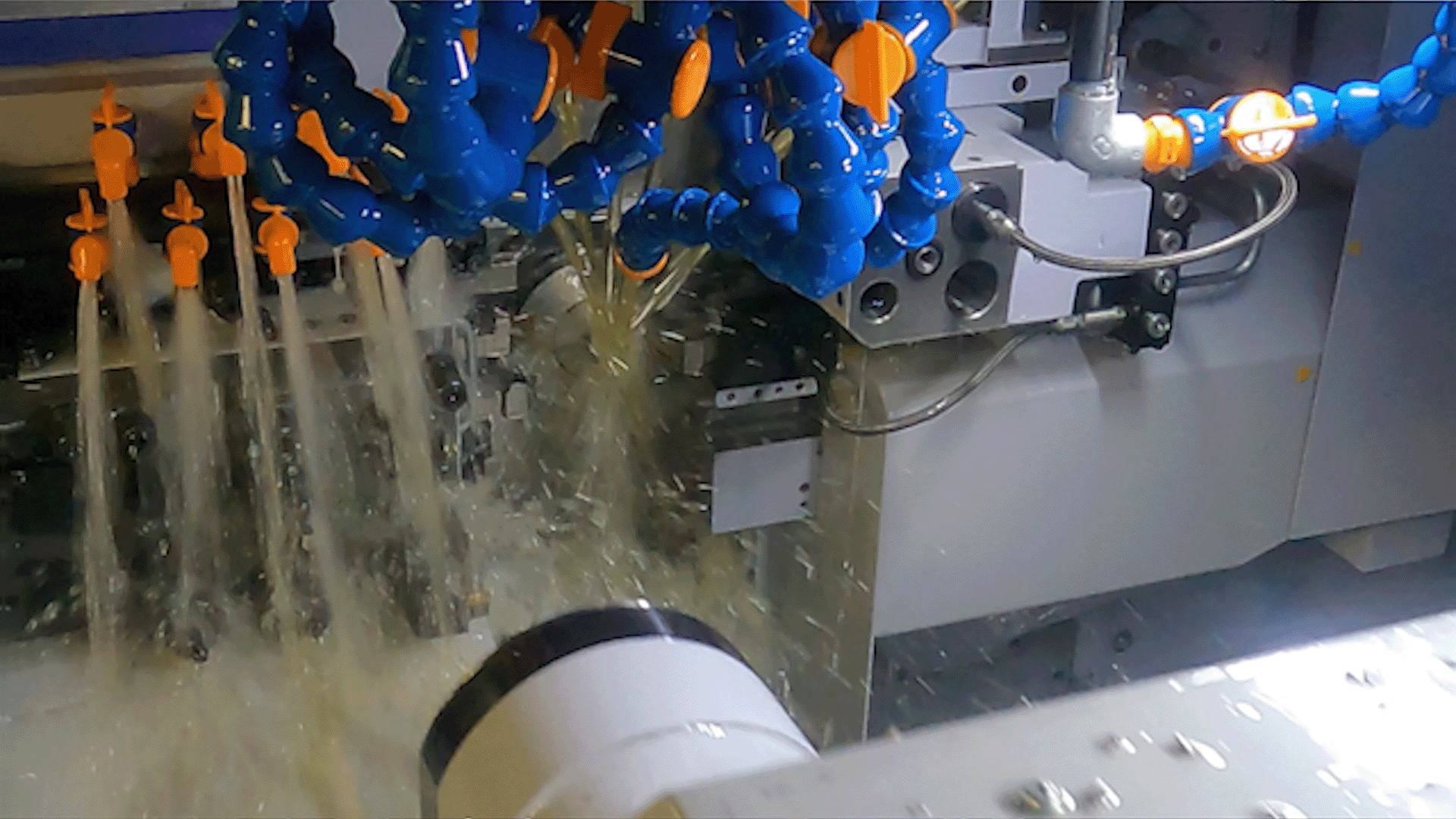

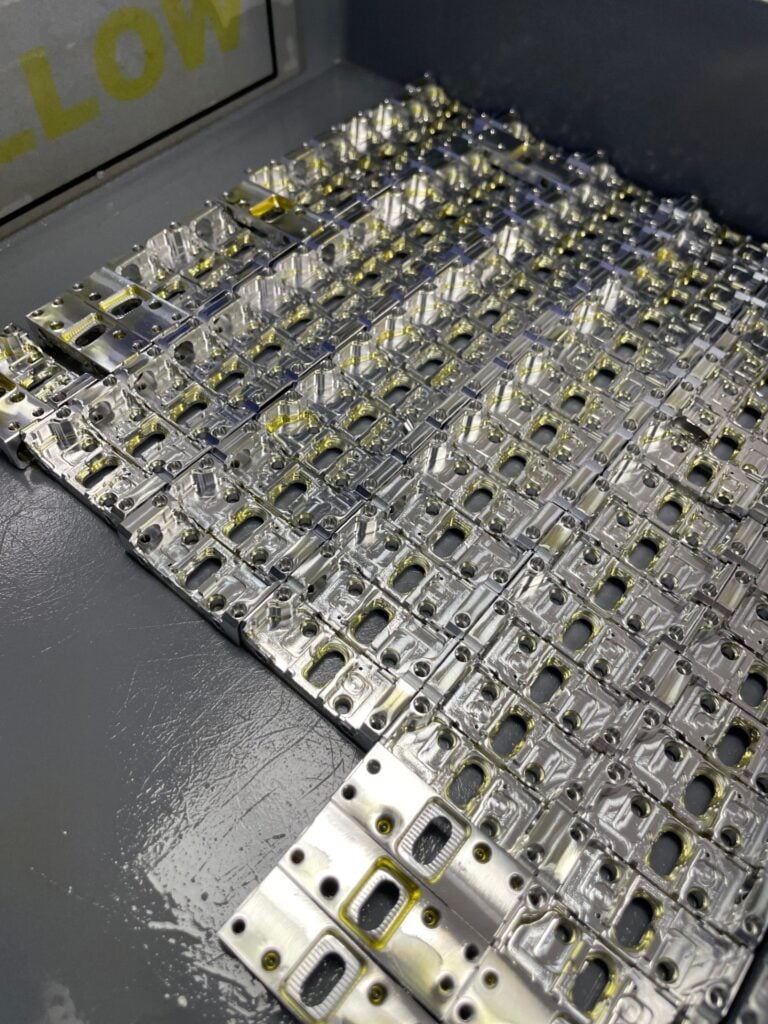

Traditionally, this family of complex parts was produced on vertical machining centres (VMCs). Components were machined in multiples, meaning operators were often tied up for an hour each shift attending the machines while also struggling to maintain tolerances over long production runs. Cycle times were slow, and operators had to continually intervene to keep the process on track.

By adopting a suite of Star sliding head lathes, Renishaw was able to rethink the entire approach. Today, parts that once required machining centres are now produced faster, with greater precision, and far more control on lathes.

Operator Time Slashed

The difference has been staggering:

- What once tied an operator up for an hour each shift now takes just seven minutes.

- One operator can now manage six machines simultaneously.

- Inspection has been moved outside of the machine, eliminating cycle interruptions and freeing up even more productive cutting time.

Setup Time Reductions Drive Productivity

Another huge win has come from the reduction in setup times. Previously, breaking down parts and setting machines for this family of components could take up to a double shift. With the new Star sliding head lathes, the same process now takes just 70 minutes.

This shift not only saves valuable hours but also ensures machines spend more time cutting and less time idle — a direct boost to throughput and productivity.

Process Control Reimagined

Perhaps the biggest leap forward is in process control. Where once operators had to constantly monitor machines, adjust parameters, and watch for tolerance drift, today the process is stable, automated, and predictable. Sliding head lathes, combined with Renishaw’s own expertise in metrology and automation, ensure consistency across long production runs with minimal human intervention.

A Lesson for UK Manufacturing

In all, this solution has completely reshaped throughput at Renishaw’s Miskin site. For UK manufacturers, there’s a powerful lesson: adopting the right technology and engineering partnerships can deliver game-changing results — helping businesses to reduce setup times, slash operator attendance, improve cycle times, strengthen process control, increase output, cut waste, and win more business.

The transformation has been so significant that MTDCNC sent both Lyndsey and Paul to Miskin to capture the full story.

🎥 Stay tuned to MTDCNC for the upcoming video feature and see first-hand how Renishaw and Star GB engineered this manufacturing masterclass.