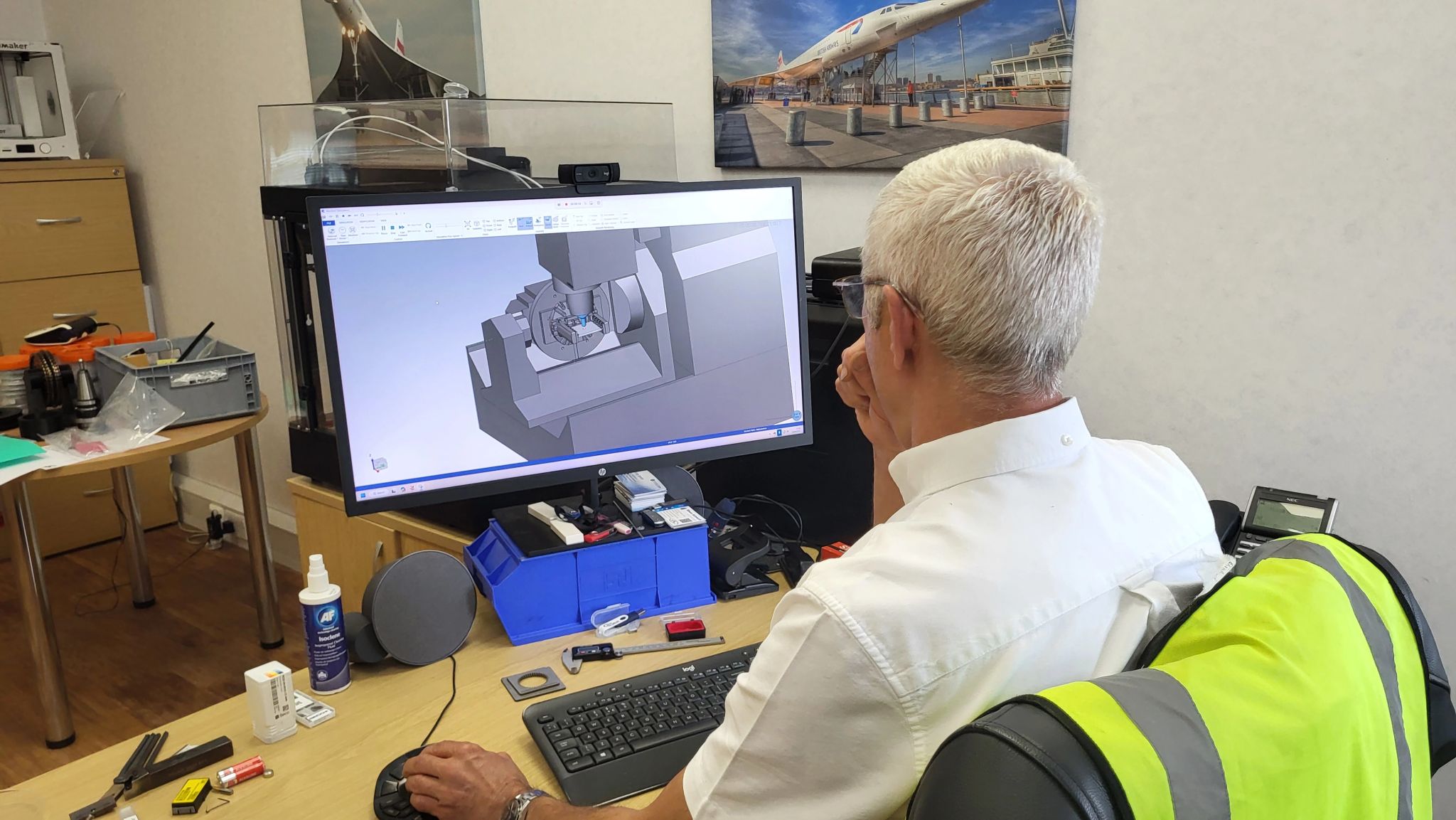

For the team at JWA CNC Precision, the answer lies in becoming true Mastercam power users.

By fine-tuning their entire workflow, they’ve dramatically reduced setup times and accelerated programming — transforming what could be a complex bottleneck into a smooth, daily achievement.

The secret? It’s all about meticulous preparation and smart use of software.

Here’s How They Do It:

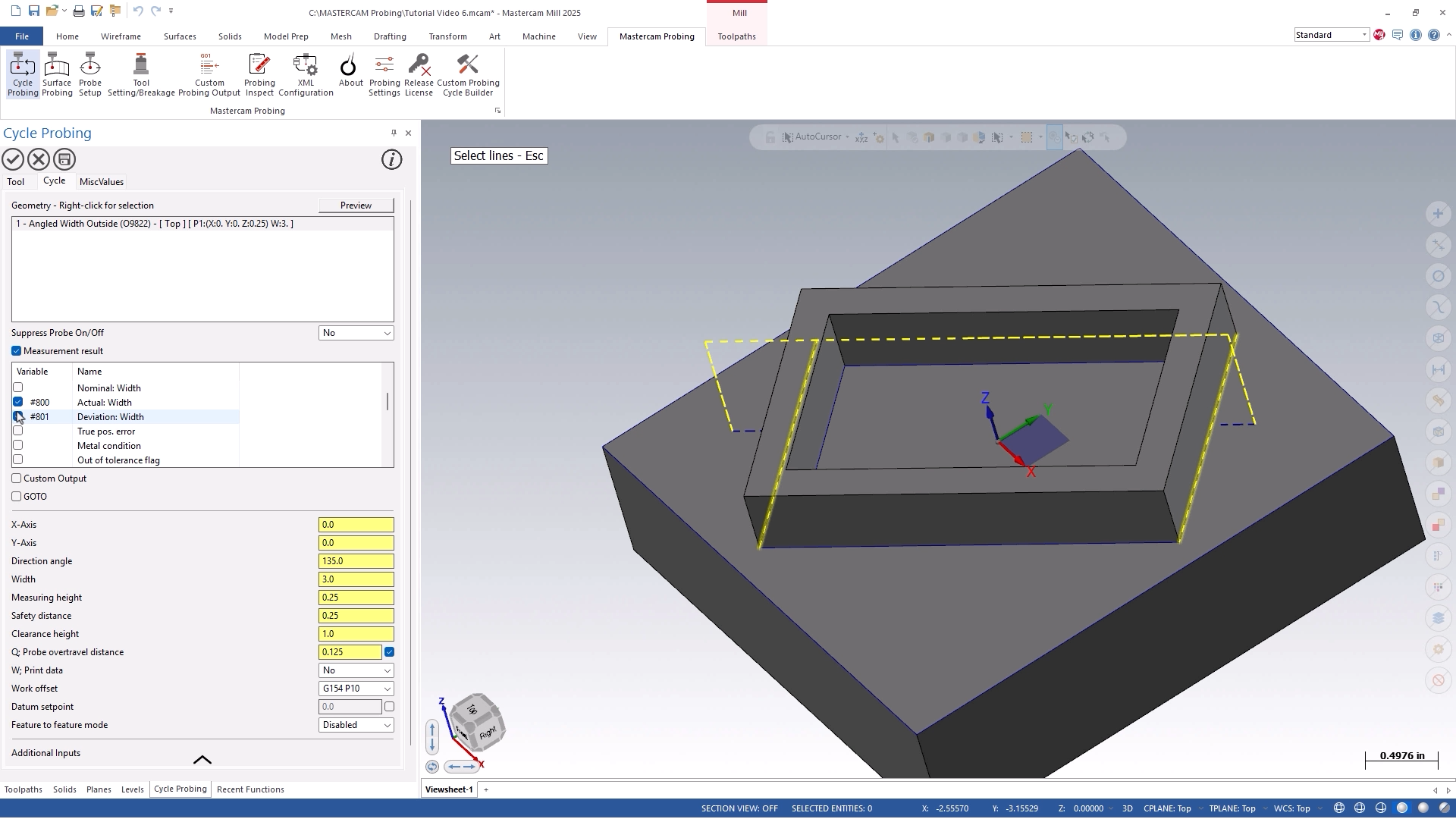

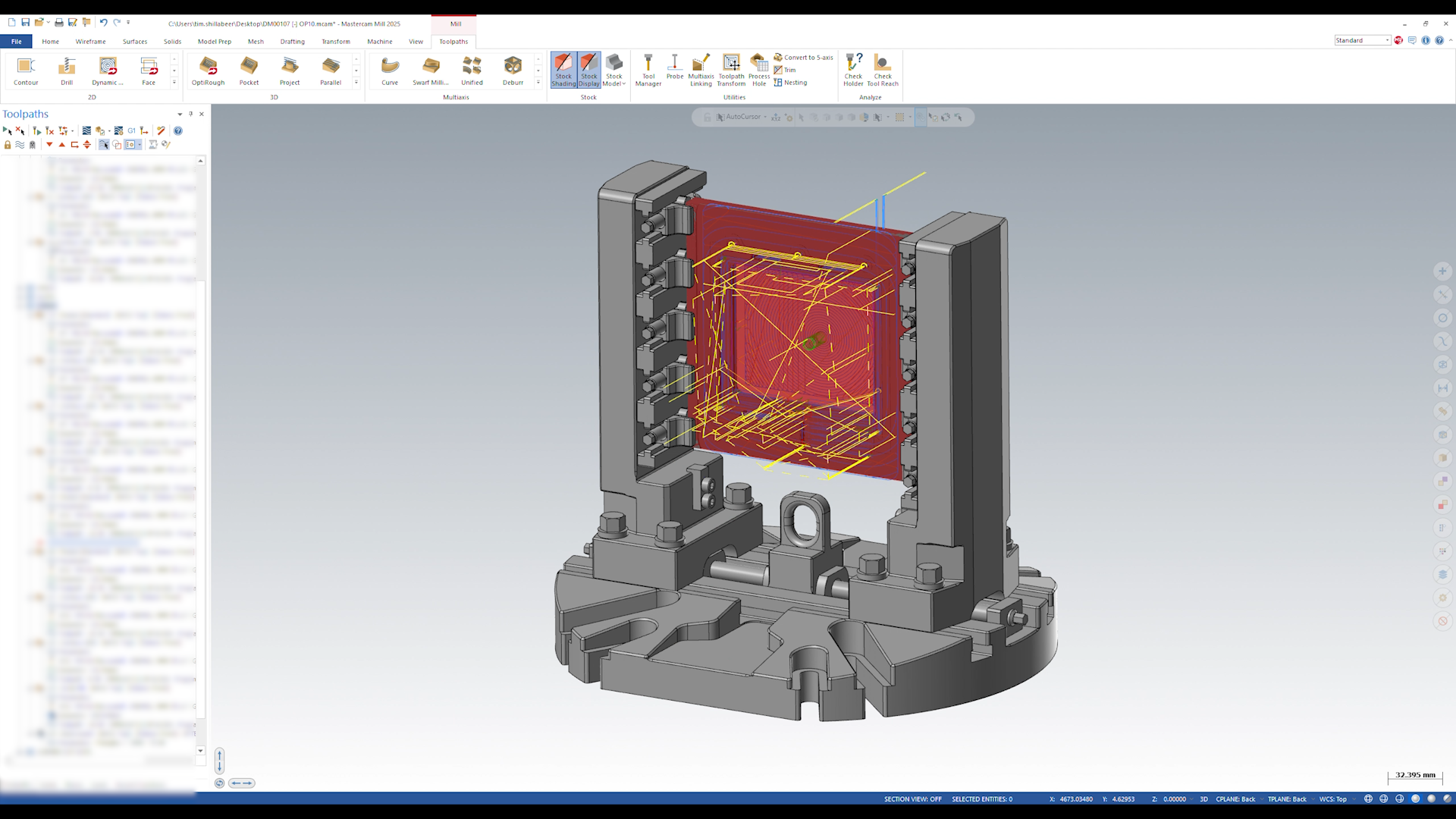

- Custom Templates – Pre-set configurations for each machine and common job types ensure programming starts on the right foot every time.

- Dialled-in Tool Libraries – Every tool is stored with the right specifications and data, ready for instant use.

- Optimised Cutting Parameters – Carefully tested settings push performance to the limit without compromising on quality.

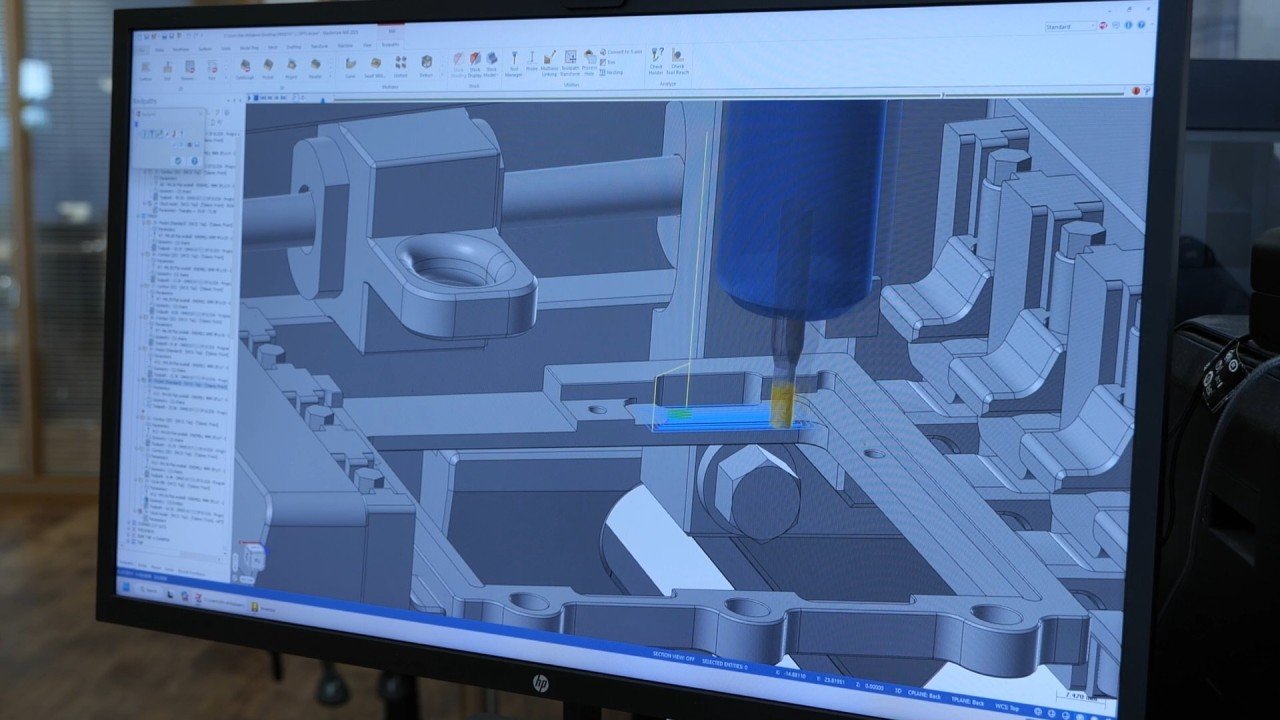

The result? An impressive two New Product Introductions (NPIs) every single day.

It’s a powerful example of how deep software customisation can drive significant efficiency gains on the shop floor — proving that the right combination of preparation, process, and programming expertise can deliver exceptional results.

🎥 Video coming soon to MTDCNC — stay tuned for the full story direct from the shop floor.