Sandvik Coromant has introduced enhancements to its CoroPlus® suite, aiming to address common production slowdowns by integrating tool availability with CAM assembly. The innovative approach combines the CoroPlus® Tool Library and CoroPlus® Tool Supply, ensuring that tool assemblies planned in CAM are synchronized with real-time inventory data.

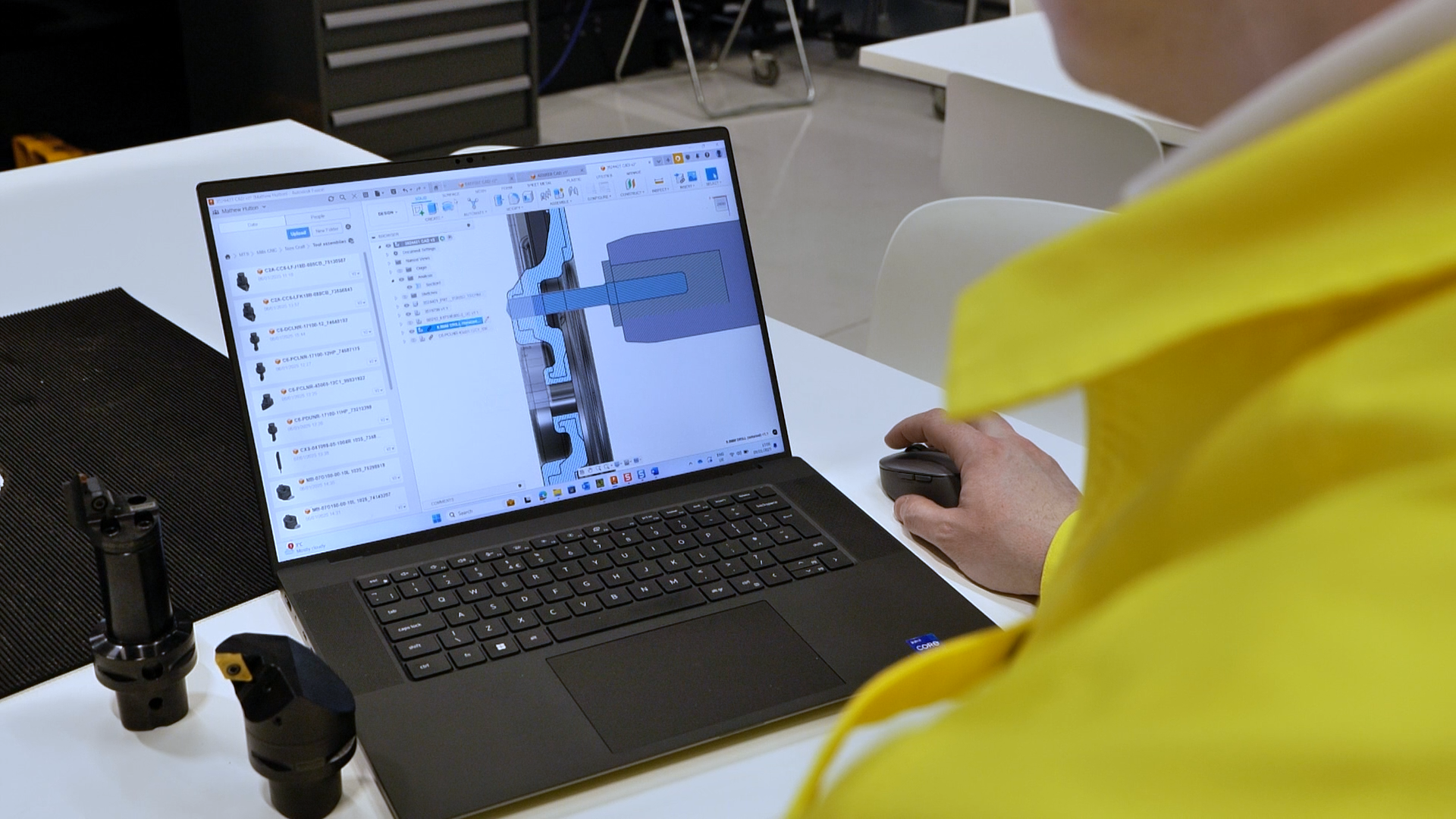

Manufacturers often face challenges when tools modeled in Computer-Aided Manufacturing (CAM) are not actually available, leading to unexpected production delays. By using verified tool data through the CoroPlus® Tool Library, manufacturers can efficiently plan their tool assemblies. This integration with CoroPlus® Tool Supply provides an up-to-date view of stock levels, usage, and replenishment needs directly from the shop floor.

Together, these tools aim to minimize production surprises, cut down on unnecessary spending, and ensure a seamless workflow. The integration promises to boost productivity by reducing interruptions, allowing more jobs to proceed smoothly.

Sandvik Coromant, a leader in the manufacturing sector known for its digital manufacturing solutions, continues to pioneer innovations that streamline production processes. The company’s CoroPlus® offering represents a significant step forward in aligning digital planning with physical inventory, crucial for maintaining efficient manufacturing operations.