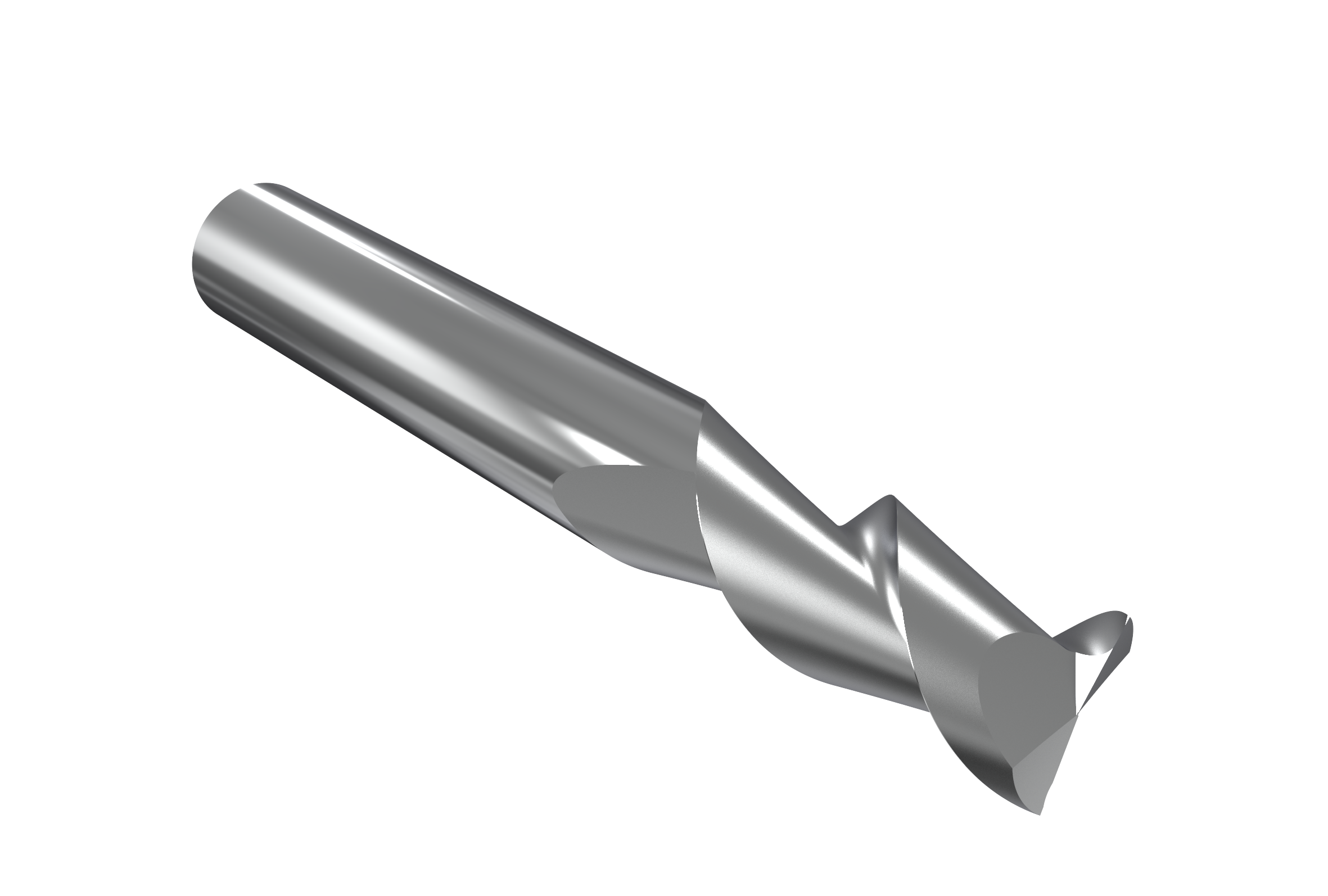

The ‘Infinite Possibilities’ mantra of the cutting tool experts at Quickgrind, has now been extended to its portfolio of 2-flute end mills. Creating what is now an unprecedented number of end mill solutions, Quickgrind has introduced its new Alligator Duo series of 2-flute end mills.

The Tewkesbury cutting tool manufacturer has launched its new Alligator Duo Series of 2-flute end mills with standard and aluminium geometries to meet the diverse application range of the manufacturing sector. The solid carbide Alligator Duo Series of end mills can be ‘designed and specified’ to the requirements of the end-user as part of the ‘Infinite Possibilities’ range.

Not setting its stall on ‘standard’ catalogue dimensions, Quickgrind is offering the new Alligator Duo Series in a complete range of lengths and diameters with the choice of a long reach and short flute geometry, a long reach and long flute or even as a stub length tool for optimal rigidity. This gives the end-user the option of additional reach with uncompromising levels of stability or stub length tools that can generate surface finishes beyond compare. Whatever the machining specifications of the customer, Quickgrind can meet the needs of the end user with a high-quality end mill that is delivered to a particularly short lead-time, a lead-time that is the envy of the industry.

The Alligator Duo is available with several geometry options to cater for applications as diverse as roughing, semi-finishing, finish machining and even profile machining. Quickgrind can also provide the new Alligator Duo Series with a square-end or ball nose configuration to cater for profile machining applications. In addition, Quickgrind can offer the Alligator Duo with a ‘zero-dished’ option for fine surface finish machining on flat surfaces.

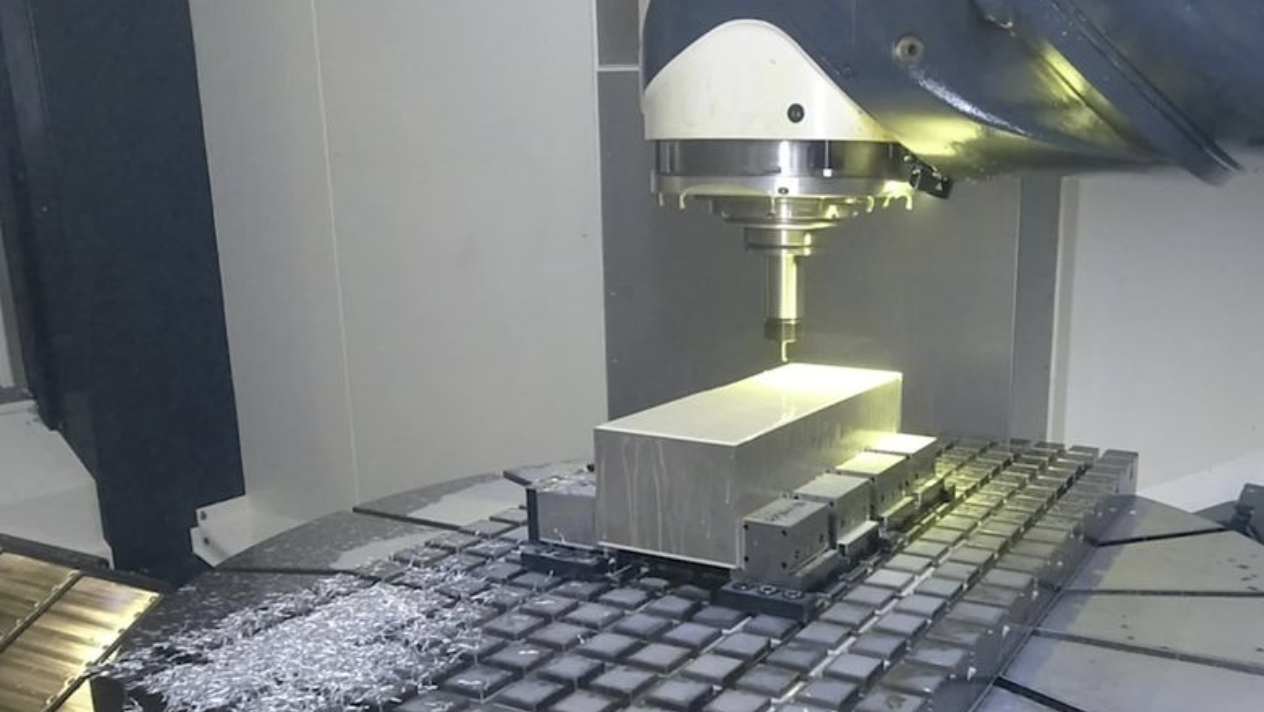

The team at Quickgrind can deliver productivity gains by optimising metal removal rates (MRR) and tool life. The in-house experts achieve this by understanding customers’ goals and then applying its proven processes and expertise to match client application requirements with the correct technology adoption.

By doing this, Quickgrind will improve performance from a productivity and cost perspective. When manufacturers realise that there is little cost difference between standard ‘off-the-shelf’ products and bespoke tailored solutions, that is when they become Quickgrind customers. The realisation that a tailored solution such as the Alligator Duo Series can reduce tooling costs, inventory and simultaneously improve productivity….is there any reason why you haven’t given Quickgrind a call?