The Nakamura-Tome JX-200 is setting new standards in the manufacturing industry with its advanced capabilities in machining complex off-centre components. Industries ranging from aerospace and medical to automotive and pump manufacturing are set to benefit from this high-performance machine, specifically designed to tackle parts with eccentric holes, grooves, or contours.

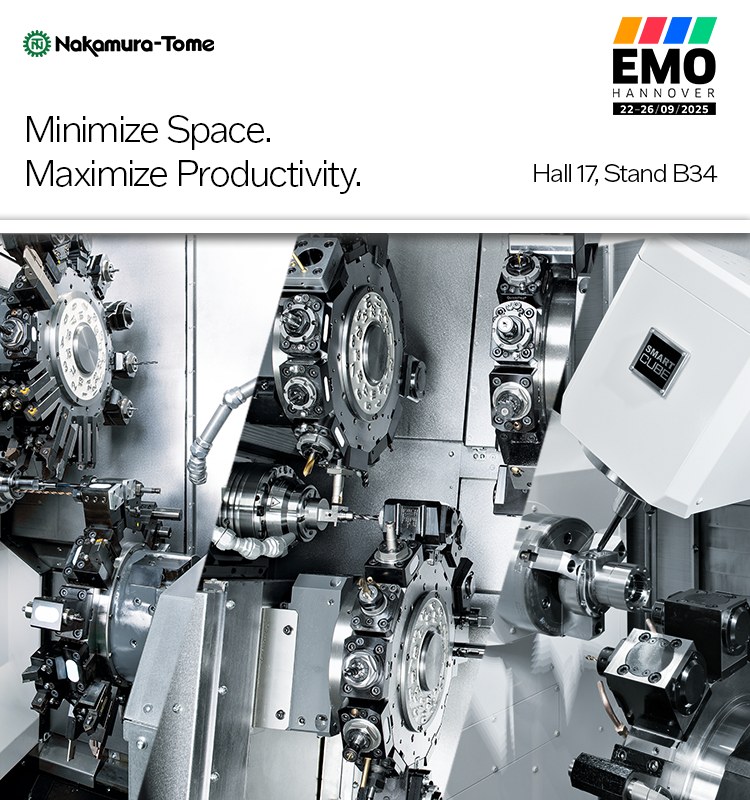

Traditionally, lathes have struggled to deliver the precise measurements required for such demanding tasks. However, the JX-200, boasting the world’s most compact tool spindle, offers exceptional accuracy and flexibility. The machine’s innovative features include eccentric drilling and turning capabilities, showcased through real cutting tests for drilling, internal diameter, and external diameter turning.

The JX-200 leverages AI Contour Control, powered by FANUC technology, ensuring smooth and precise toolpaths even in the most complex operations. Its Servo Learning Control further enhances roundness and dynamic response, providing flawless machining results. This combination of advanced features results in unparalleled precision, enabling manufacturers to enhance their production capabilities and maintain a competitive edge in the market.

ETG UK & Ireland is promoting this state-of-the-art equipment, encouraging manufacturers to explore new levels of machining precision. Potential customers are invited to contact their Regional Business Manager or reach out to ETG directly on 01926 818 418 for more information.

By integrating the JX-200 into production lines, manufacturers can achieve an unprecedented transformation in their machining processes, aligning with ETG’s mission to drive innovation within the industry.