System Performs High-Precision Welds with No Operator Intervention!

By Ashutosh Arora

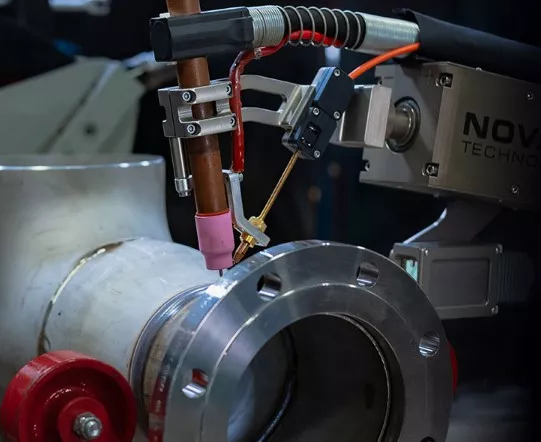

Novarc Technologies Inc. has introduced the SWR+TIPTIG Autonomy system, a fully autonomous solution for high-precision TIG welding. Designed to combine the quality of traditional TIG with the speed and productivity of MIG, the system marks a significant leap forward in automated welding technology, offering manufacturers a new level of efficiency, consistency, and labor savings.

The system is engineered for compactness and versatility, with a footprint of just 4 by 4 feet and the ability to accommodate up to four positioners. This makes it suitable for deployment in space-constrained environments without sacrificing throughput. According to Novarc, the SWR+TIPTIG Autonomy delivers X-ray-quality TIG root welds, ensuring the high integrity required in industries such as oil and gas, energy, pressure vessel manufacturing, and heavy equipment.

A defining feature of the system is its autonomous operation. Once the setup is complete, the operator can simply initiate the weld and move on to the next task. This level of automation dramatically reduces the need for operator supervision, freeing skilled welders to focus on higher-value activities while maintaining weld quality across long production runs.

In terms of performance, Novarc reports that the SWR+TIPTIG Autonomy achieves up to a 2.6-times increase in weld deposition rates compared to conventional TIG welding. It can deliver up to 4 lbs. of deposition per hour, a figure that rivals processes typically associated with higher productivity but lower precision. Additionally, travel speeds can increase by as much as 300 percent compared to traditional TIG setups, ensuring faster project completion without compromising weld integrity.

The combination of higher deposition rates, faster travel speeds, and fully autonomous operation provides manufacturers with significant advantages. Not only does the system help reduce cycle times and boost throughput, but it also ensures consistency and repeatability—factors critical in industries where weld quality is tied directly to safety and regulatory compliance. By automating precision welding, the system reduces variability caused by operator fatigue or human error, delivering uniform results across every weld.

The SWR+TIPTIG Autonomy also supports workforce challenges faced by many fabricators. With skilled welders in short supply, automation provides a path to maintaining high production capacity without overburdening existing staff. Operators can oversee multiple systems simultaneously, increasing overall productivity while still ensuring that the welds meet stringent quality standards.

By bridging the gap between TIG’s renowned precision and MIG’s efficiency, Novarc has created a solution that redefines expectations in automated welding. For manufacturers seeking to balance speed, quality, and labor efficiency, the SWR+TIPTIG Autonomy offers a compelling way to advance welding operations while positioning themselves for future competitiveness.