MELD Unveils DragonForge Series Metal AM Machines for Large-Scale Aerospace Alloy Parts!

By Ashutosh Arora

MELD Manufacturing Corporation has announced the launch of its DragonForge Series, a next-generation line of metal additive manufacturing (AM) machines designed to address the challenges of producing large-scale aerospace alloy parts. The new series is engineered specifically for high-performance materials such as titanium and high-strength aluminum alloys, including the AA7XXX family, and is capable of delivering parts that meet or exceed traditional forging standards.

According to MELD’s CEO Nanci Hardwick, the DragonForge represents years of hardware and software innovation aimed at redefining how aerospace components are manufactured. “This equipment is truly next generation capability for rapid 3D printing of large aerospace parts,” she said. With processing enhancements that enable the successful deposition of complex aluminum alloys like Aluminum 7075, the DragonForge offers both the mechanical integrity and reliability required by demanding aerospace applications.

One of the most notable advancements in the DragonForge Series is the integration of a digital twin. This virtual model of the machine allows users to simulate print strategies, run code, and confirm processes before committing to a physical build. By testing and refining operations in a digital environment, operators can identify potential delays, optimize parameters, and maximize efficiency while reducing material waste. This feature enhances machine autonomy, improves user interaction, and provides robust monitoring capabilities, further streamlining production.

The DragonForge also reflects MELD’s focus on industrializing its patented solid-state additive process, which creates parts without melting the material. The result is a forged-like structure with superior strength, durability, and resistance to defects typically associated with melt-based 3D printing methods. By combining scalability with forging-quality outputs, the DragonForge addresses critical gaps in the aerospace and defense supply chain, where access to forgings remains a bottleneck.

Industrial adoption of this technology promises to deliver significant benefits, from reducing lead times and production costs to lowering energy consumption and space requirements on the manufacturing floor. By enabling printed forgings on demand, the DragonForge allows manufacturers to repair and replace legacy components, produce critical parts rapidly, and respond to supply chain disruptions with agility. For industries where mission-critical parts made of aluminum and titanium are essential, the ability to move from design to deployment in weeks rather than months or years represents a transformative advantage.

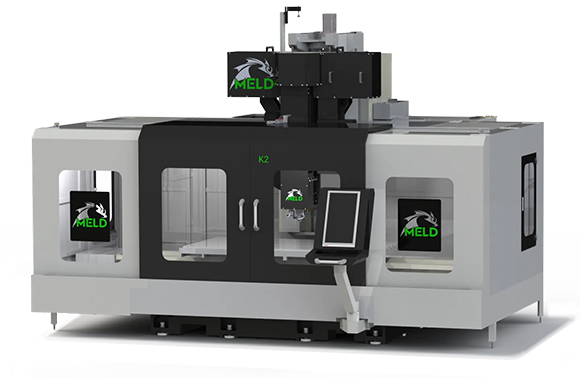

The DragonForge series is available across MELD’s L3, K2, 3PO, and CD-14 platforms, providing flexible options for customers based on their application requirements.

MELD Manufacturing, headquartered in Christiansburg, Virginia, has established itself as a leader in additive manufacturing through its patented solid-state MELD process. Unlike traditional AM systems that rely on melting, MELD’s technology enables open-atmosphere printing, faster production speeds, and the creation of large, defect-free metal parts. Its systems are used across sectors including aerospace, defense, energy, and space, offering unique solutions for both manufacturing and repair.

With the introduction of the DragonForge Series, MELD continues to advance the boundaries of metal additive manufacturing, bringing aerospace-grade, forging-quality components into the realm of rapid, flexible, and sustainable production.