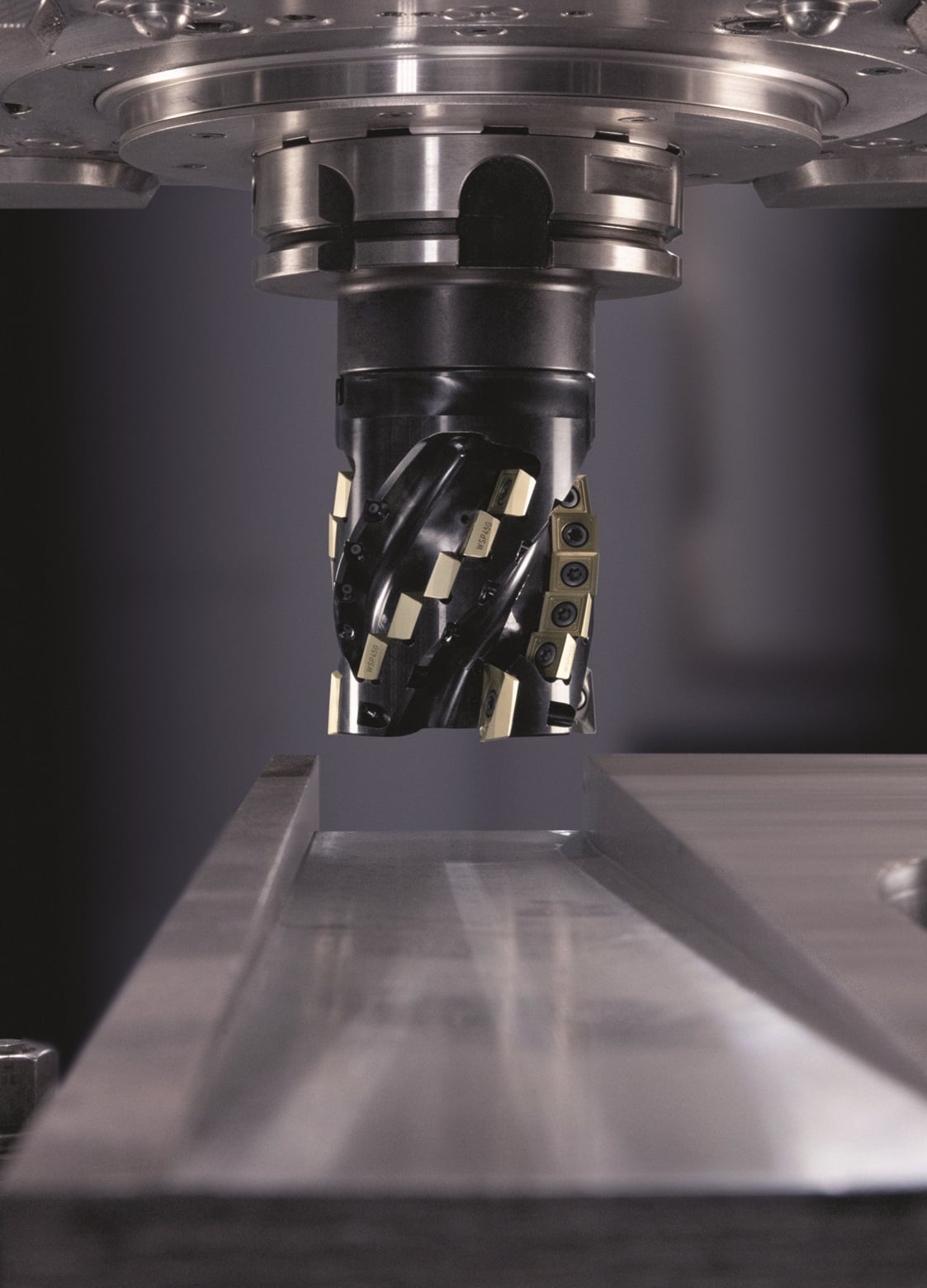

Walter Tools has introduced a new feature within its Walter GPS software, aimed at improving sustainability in machining operations. The inclusion of a sustainability tab highlights the company’s commitment to reducing the carbon footprint associated with machining processes.

In a recent episode of Tech Talk, experts Brian Schultz and Cornelius Aichele discussed the enhancements to Walter GPS, detailing how it supports smarter and more environmentally-friendly machining decisions. The software now enables users to calculate CO₂ equivalents for various applications, taking into account machine power, idle time, and energy use.

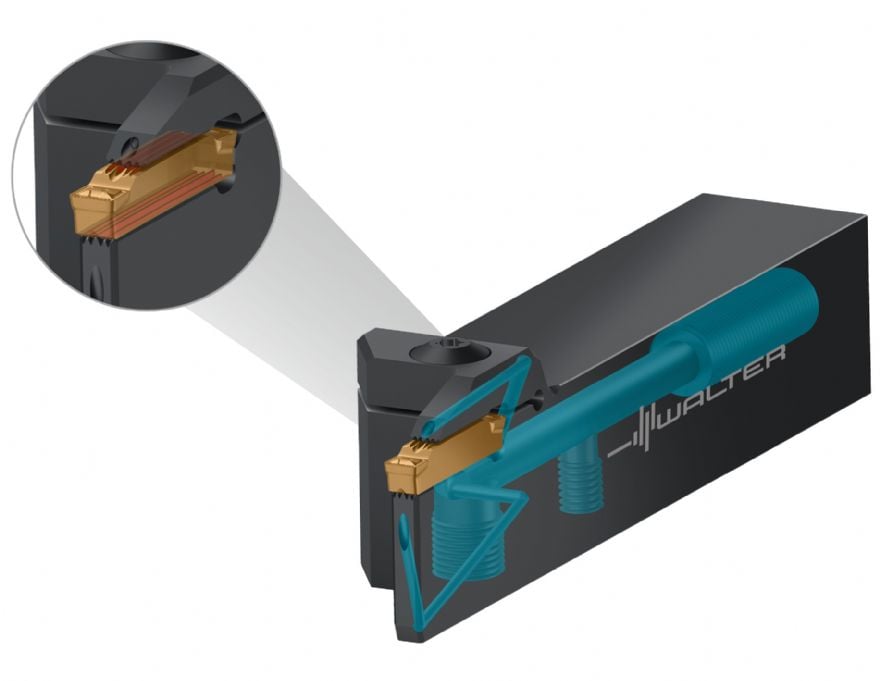

One of the standout features is the ability to understand how tool size affects energy consumption, allowing shops to make informed decisions that minimize waste and reduce idle time. This approach not only boosts operational efficiency but also contributes to a more sustainable industry.

The new feature is part of Walter Tools’ broader strategy to integrate sustainability into its product offerings, ensuring that users have the necessary tools to make greener choices without compromising on performance or productivity.

Walter Tools, a leading provider of machining solutions, continues to innovate with a focus on sustainability, aiming to create positive change within the manufacturing sector. This development is expected to be instrumental in guiding companies towards more environmentally-responsible practices without sacrificing operational effectiveness.