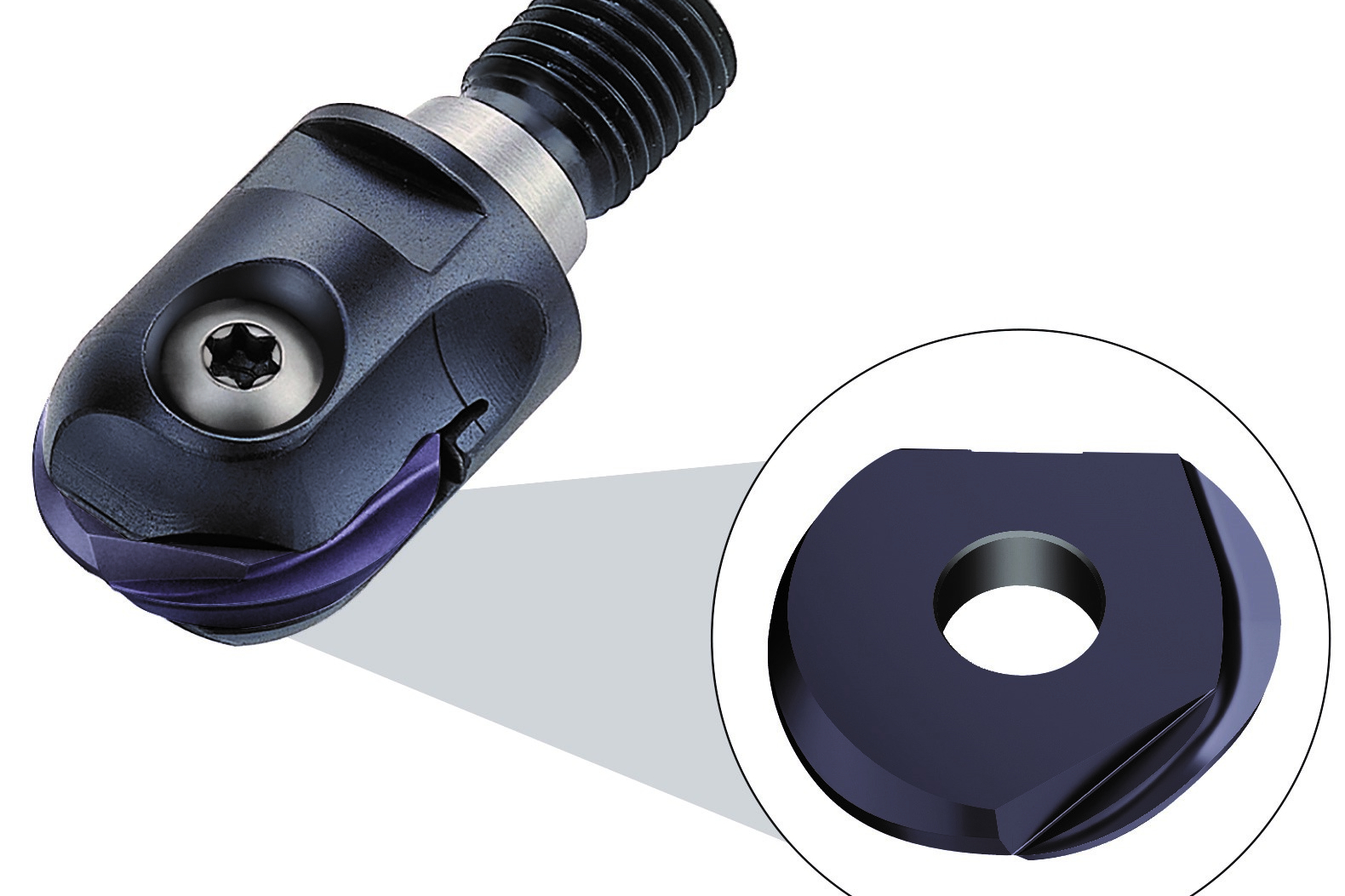

Walter says its new physical vapor deposition- (PVD) coated WHH15X milling grade excels at finishing and semi-finishing hardened components up to 63 HRC, as well as finish-milling steel and cast-iron components when using wiper inserts. Finish machining of a component is said to be possible with a single cutting edge.

The WHH15X grade can reportedly provide extra-long tool life, especially with hardness of 58 HRC or greater. The new grade can be used universally for finishing on ISO materials P, K and H, and is said to be ideal for copy milling in die and mold making. It provides high surface quality due to its wear resistance and edge stability, and yields cost savings by reducing the need for manual rework when copy forming.

The WHH15X grade features high-power impulse magnetron sputtering (HIPIMS) technology for excellent coating adhesion and a high degree of hardness, and AlTiN coating optimized for hard machining. Walter says this results in an extremely smooth surface for the best chip removal and high surface quality. This new grade also has a wear-resistant carbide substrate and is available for tools for copy milling and finish milling, including the F2234 and F2231 round insert milling cutters, the F2139 profile milling cutter, the M5008 high feed milling cutter, as well as the SDHX, BCGX and LNHX wiper inserts.