Horn Turning Tool Enhances Threading Capabilities!

By Ashutosh Arora

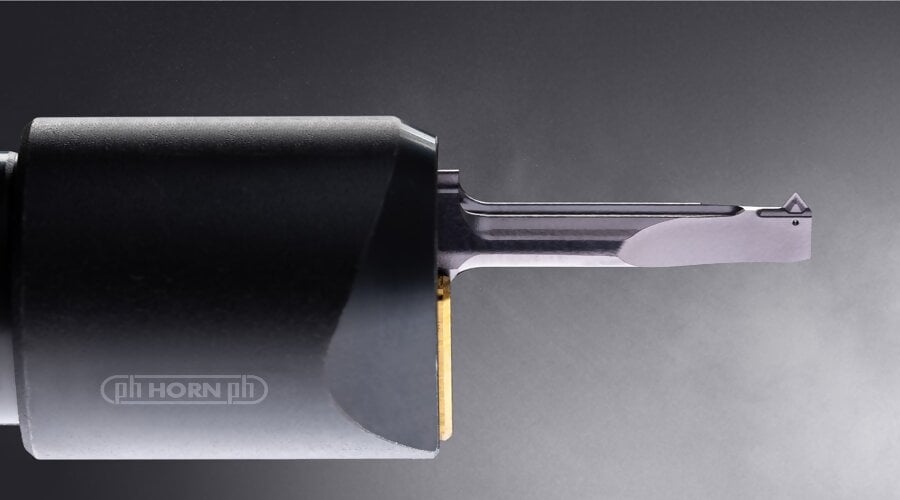

Horn USA Inc. has expanded its well-known Supermini system with the launch of sintered GM-geometry inserts, designed specifically for internal threading applications. This addition enhances the versatility of the Supermini range and addresses common challenges in threading operations by improving chip control, process stability, and ease of integration.

The new GM-geometry inserts are engineered for turning metric ISO partial profile internal threads. A particular strength of the design is its ability to deliver reliable chip control, even when working with difficult, long-chipping materials. Threading operations often face problems such as chip buildup or tangling, which can disrupt the process and lead to tool damage or component quality issues. The GM-geometry inserts overcome these challenges with an optimized chipbreaker design that consistently produces short, manageable chips.

By ensuring clean and controlled chip formation, the inserts reduce the risk of interruptions during production, improving overall process reliability. This directly contributes to higher productivity, as operators can maintain stable machining conditions without frequent stoppages to clear chips. Simplified chip management also improves operator efficiency, reducing downtime and lowering the chance of toolholder or workpiece damage caused by uncontrolled chip flow.

The inserts are suitable for core hole diameters starting at 5 mm (0.197 inches), with pitch sizes ranging from 0.5 mm (0.028 inches) to 1.5 mm (0.060 inches). This range enables manufacturers to tackle a wide variety of small-diameter internal threading applications with precision and repeatability. The geometry is particularly beneficial in industries where fine internal threads are common, such as medical devices, aerospace components, and precision engineering.

Compatibility has been made a priority in the design of the GM-geometry inserts. They integrate seamlessly with standard Horn Supermini toolholders, allowing manufacturers to enhance their threading capabilities without investing in new toolholding systems. This ease of adoption ensures that shops already using the Supermini system can quickly expand their range of applications, adding more value to their existing tooling investments.

The expansion of the Supermini line reflects Horn’s continued commitment to providing high-performance solutions for complex machining tasks. The company’s focus on developing geometries that address practical challenges—such as chip control in threading—demonstrates its understanding of the needs of modern manufacturers striving for both efficiency and reliability.

Threading is a critical operation in many industries, often requiring precise tolerances and high surface quality. With the new GM-geometry inserts, Horn is giving manufacturers the tools they need to perform internal threading more confidently, even in demanding materials. The combination of chip control, stability, and compatibility makes the inserts an important addition to the Supermini family.

By expanding its Supermini system with these innovative inserts, Horn USA is reinforcing its role as a leader in tooling solutions for precision machining. The sintered GM-geometry inserts exemplify how thoughtful tool design can address longstanding industry challenges, supporting manufacturers in achieving higher productivity, better quality, and smoother machining operations.