W

ithin the aerospace sector OEMs and subcontractors alike machine a wide range of materials, some difficult, some relatively easy. Here at Quickgrind, we have developed many ranges of solid carbide cutting tools that have proven very successful whether endmills, high feed, special tools or barrel-type tools.

Let’s take a look at three examples – the Caiman, the Mirage and the Eliminator. The Quickgrind Caiman is a high-performance range of end mills for machining 6000/7000 aluminium and it is available with various corner edge preparations such as chamfer, radius or square end in diameters from 3 to 25mm with 3 or 5 flutes. When looking at improving productivity with trochoidal milling, we also offer all of these tools with chip breakers. This enables our tools to achieve full flute engagement with the benefit of producing small swarf chips that are easy to handle and do not disrupt the machining process. The tool dimensions are offered in stub, standard and long overall lengths with a vast variety of flute lengths to suit your applications.

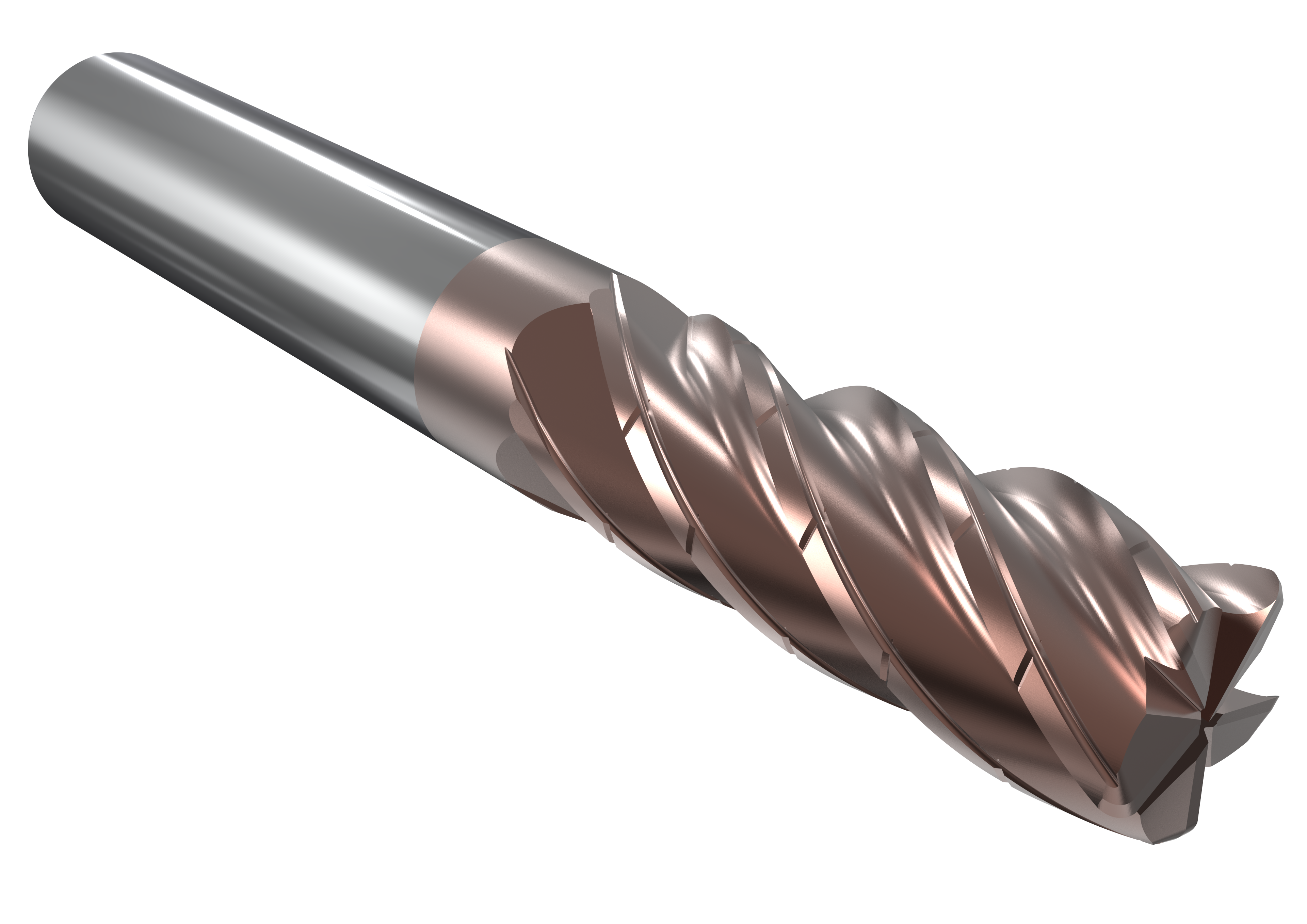

The Mirage is a favourite when machining heat-resistant materials such as stainless steel, titanium and inconel. Available in 4, 5, 7 or 9 flutes with chip breakers if required and in virtually any combination of overall length and flute plus radii you can think of! When the application requires that bit extra, we now have our Mirage Super which is capable of achieving excellent performance especially in roughing operations. With diameters from 3mm to 25mm, we can support your requirements at every step.

‘Eliminator’ was chosen as the name for our barrel tool range because this is what it does, it eliminates your frustration with long finishing cycle times. Available in conical, tangential, lens and Type F forms, we have also recently introduced our new concave form. These tools are transforming finishing strategies in a variety of components from blisks and impellers (multiple or single-bladed) to aluminium aircraft structures with deep pockets and side walls. Replacing the need for time-consuming scanning with ballnose endmills, our tools are available in bespoke tailor-made forms with deliveries of 2-3 working weeks for the standard series. With these groundbreaking tools, full application support is available – all the way from tool design to prove out and application.

The new concave barrel tool is an exciting new addition to our range and it is designed with a concave flute as opposed to a convex flute. This exclusive new design from Quickgrind has been developed by our R&D engineers over the past 18 months. It has proven to be an excellent tool for components with convex surfaces such as femoral knee joints for example. We are currently running trials on some aerospace and motorsport parts and the early results are very positive.