🎧High-precision grinding is an art

Starting a business requires risk-taking. “It’s like a motorcycle race. If you don’t want risks, you might miss your chance to win,” says Randy Gevers, CEO of GRT-Tech. Passionate grinder Randy Gevers knows his stuff. Before founding his company, he enjoyed years of success in motorcycle racing. But his success story begins with his father, Antoon Gevers, who instilled a love for engines and metalworking, especially grinding.

After years of working together, the Gevers family took the plunge in 2016 and started their own business. The first machine Randy bought was a conventional grinder, with others quickly following. Fittingly, their initial customers came from the KTM community, as the family had built an extensive network through racing.

Today, customers from aerospace, medical technology, tool and mould making, trust the Gevers, alongside navy suppliers and semiconductor industry suppliers. “Theoretically, we could survive on semiconductors alone,” says Randy. “But a company shouldn’t become dependent on one sector.”

The range of materials at GRT-Tech extends from steel, various stainless steels, brass and copper to ceramics and plastics. Typically, small batches of up to around 50 pieces are manufactured, but individual parts and prototypes are also produced.

Precision Demands Better Equipment

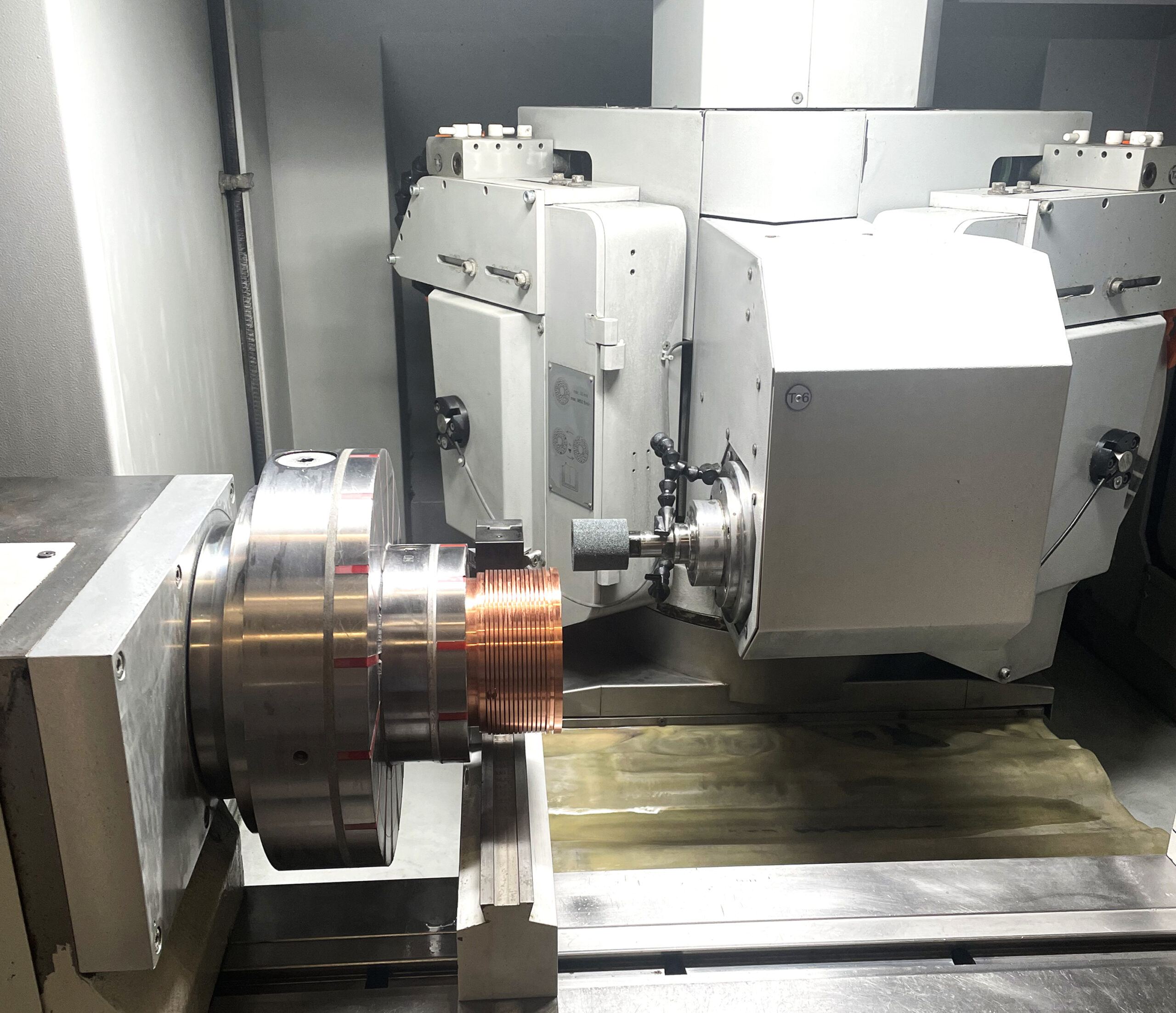

Randy quickly realised that machining complex workpieces, such as those used in tool and mould making or medical technology, reached its limits with conventional grinding machines. After moving to their current location in 2018, he purchased a powerful, used KELLENBERGER KEL-VARIA CNC universal cylindrical grinding machine.

Right from the start, we received many requests for grinding complex workpieces,” says Randy. “But we could only accept around 10% of them. I couldn’t, and didn’t want to, continue like that.” The decision wasn’t difficult—both Gevers knew and valued these machines from their previous employer.

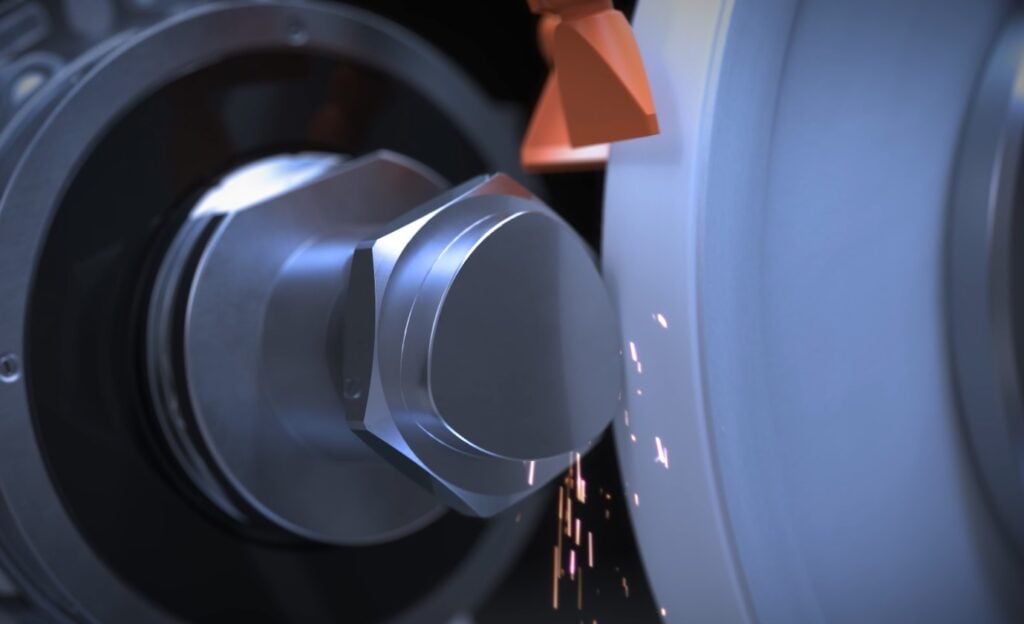

The KEL-VARIA, a predecessor of today’s premium KELLENBERGER K1000 series, embodies the highest machining and surface quality. It has very high static and dynamic rigidity that ensure the machine delivers precise and efficient operation.

Expanding Capabilities

Following a positive experience, another KELLENBERGER machine was quickly shipped to Heeswijk-Dinther: a universal internal and external cylindrical grinding machine KELLENBERGER K100. René van der Peet from BMT Bridgeport Machine Tools, which represents KELLENBERGER in the Netherlands, served as a consultant.

The KELLENBERGER K100 is available with centre distances of 1,000/600mm and a 200mm centre height, designed for workpiece weights of up to 150kg. High grinding wheel drive power ensures increased productivity, while the Z-guide maintains high profile accuracy. The C-axis with direct drive offers greater precision in non-circular grinding.

Randy selected the longer 1,000mm overall length for greater flexibility in part sizes, along with a grinding head variant featuring two external grinding spindles, one internal grinding spindle, and a tactile measuring head. The high-frequency spindle, with a speed range of 6,000 to 40,000 rpm, includes an internal coolant supply.

“I’m fascinated by the machine’s high, reliable accuracy. Added to that are my years of experience, which ultimately makes the difference for the customer,” says Randy, adding with a laugh: “A machine can’t advise on how best to manufacture a workpiece.”

Mastering Complex Challenges

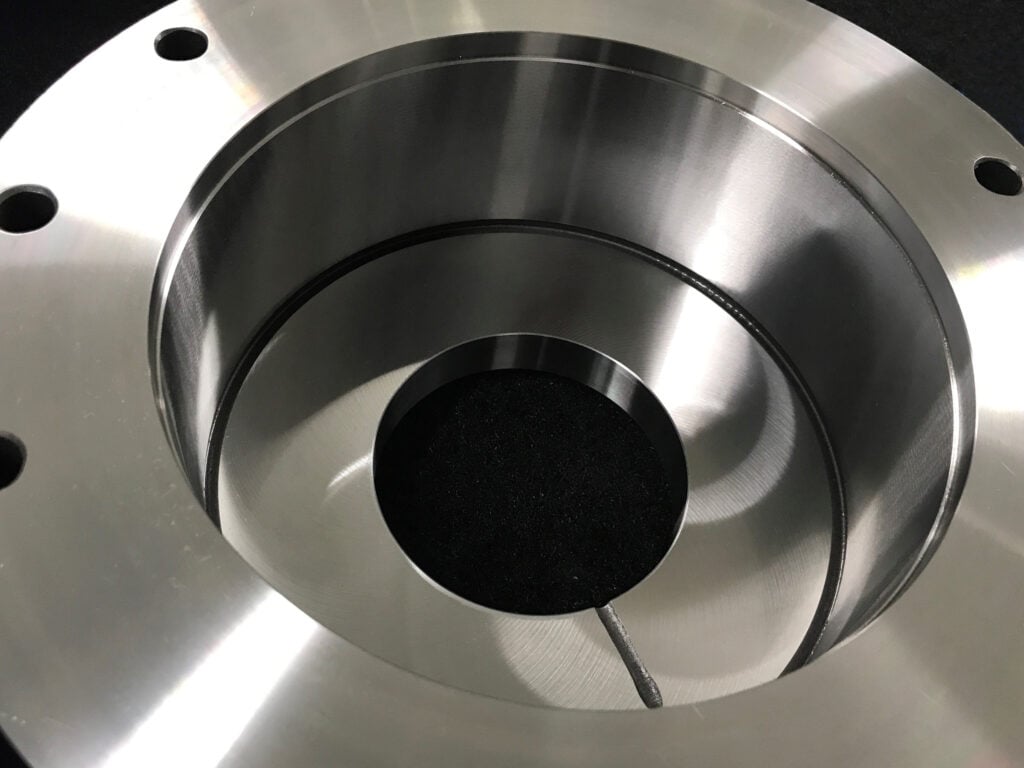

Challenging workpieces are a daily task at GRT-Tech, such as components that combine copper and cast iron with the roughness of less than 0.15µm. “We could achieve 0.05µm, but that’s not necessary in this application,” explains Randy.

“Cast iron is very porous and brittle; the grinding stone clogs quickly and must be dressed continuously, but not too often. It’s about finding the right balance. The more experience and sensitivity a grinder has, the more precise such workpieces will be. This component is very expensive due to material combination and upstream processes like turning, milling and EDM. The grinding process must be perfect first time.”

“The more complex the workpiece, the higher the precision requirements, the greater my motivation to perfect it,” says Randy. He simply loves a challenge—no longer at the racetrack, but with his machines, for his customers’ benefit.