Setup reduced from over a shift to just 70 minutes?!

By Lyndsey Vickers

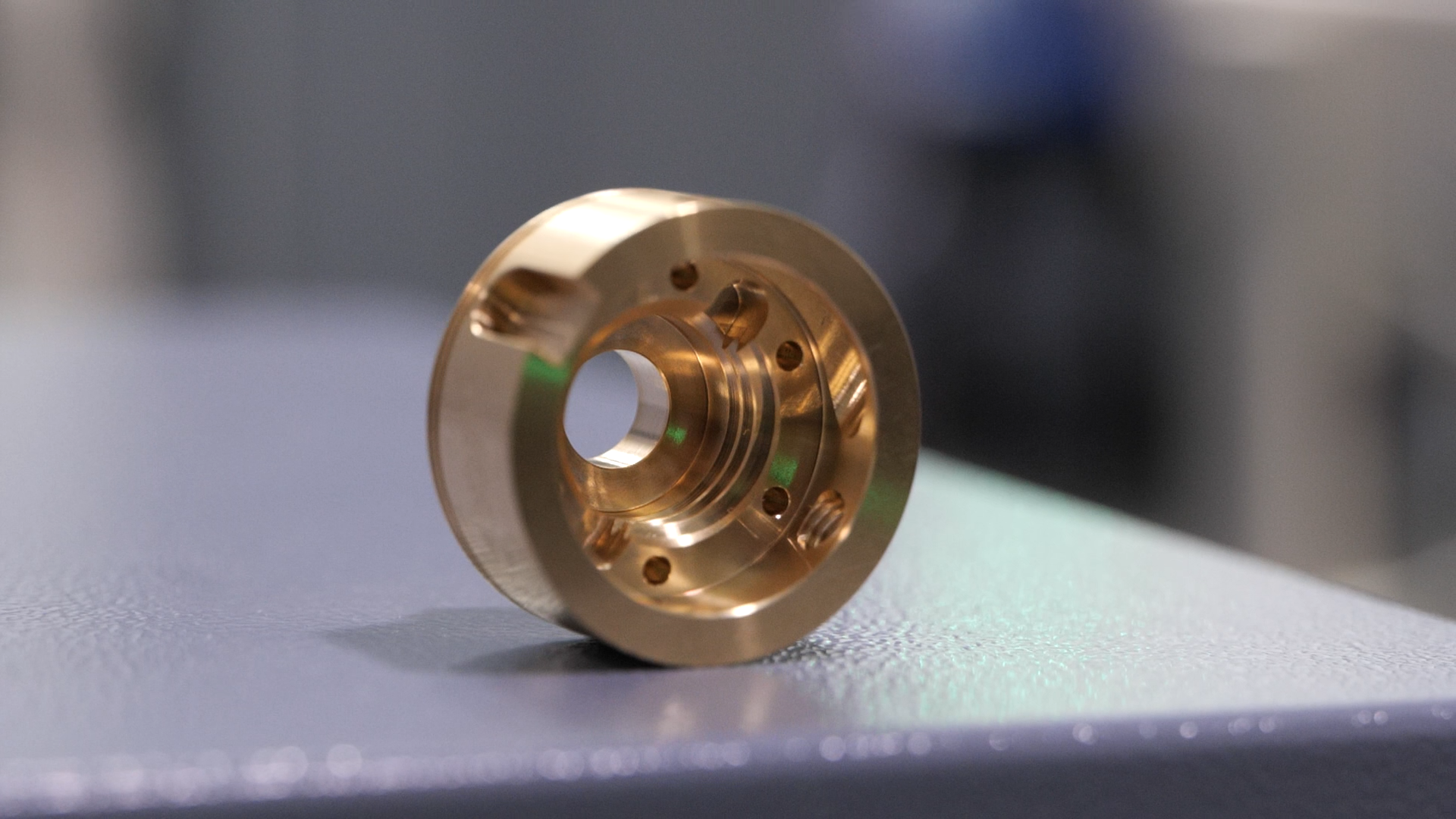

Renishaw was looking for an opportunity to reduce manufacturing cost and scale production for a family of complex parts. The solution wasn’t just buying new machines…

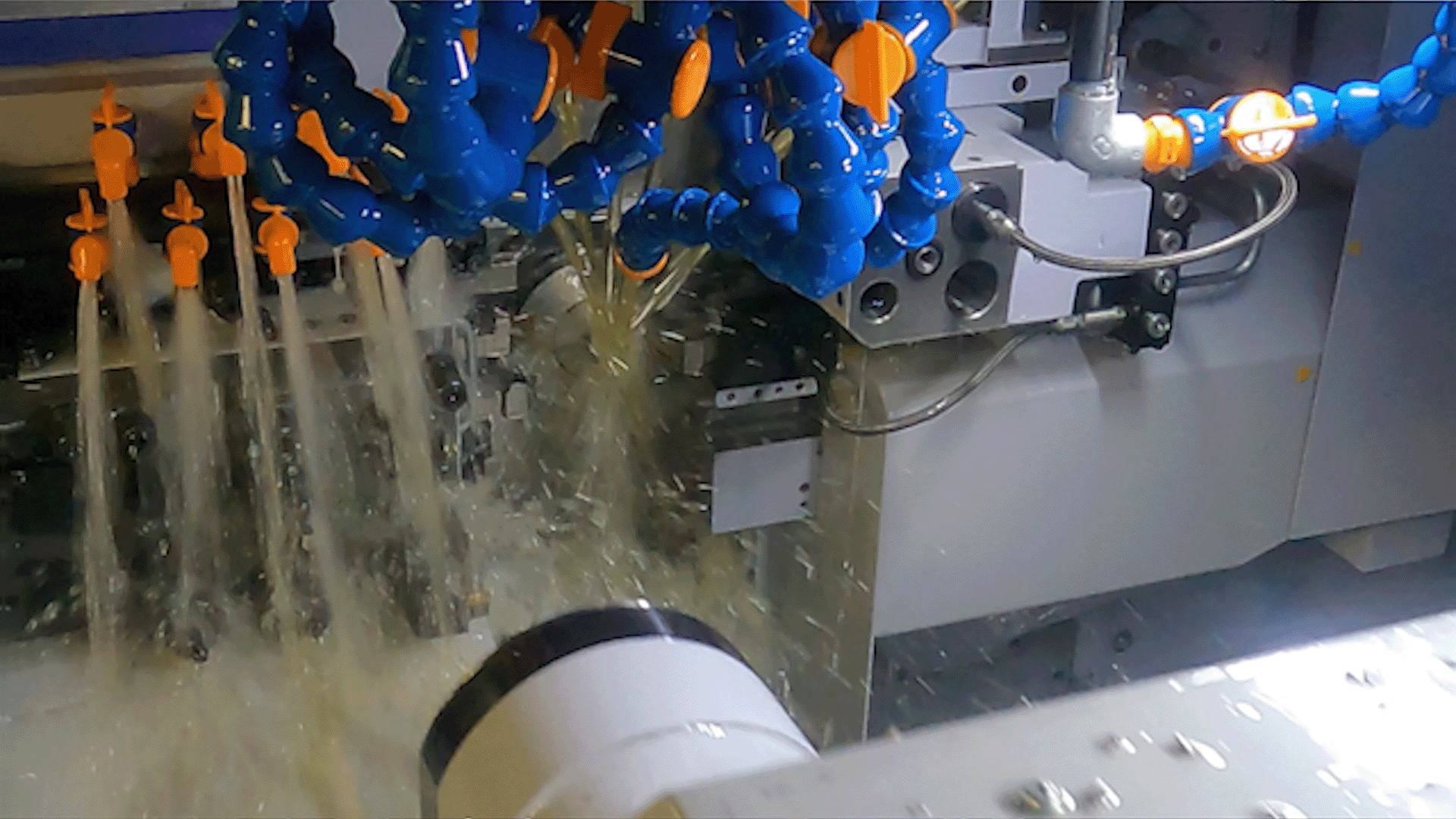

It was a collaboration with StarGB that combined high-performance sliding head lathes, Renishaw’s Equator gauging, Renishaw Central, and data-driven automation.

The result? Setups reduced from over a full shift to just 70 minutes — and operator intervention slashed from an hour each shift to only 7–10 minutes. This is total process control in action! Join Lyndsey Vickers and Paul Jones of MTDCNC as they dive into this groundbreaking project with Renishaw’s David Miles and James Hartley, and Alec Warner of StarGB.