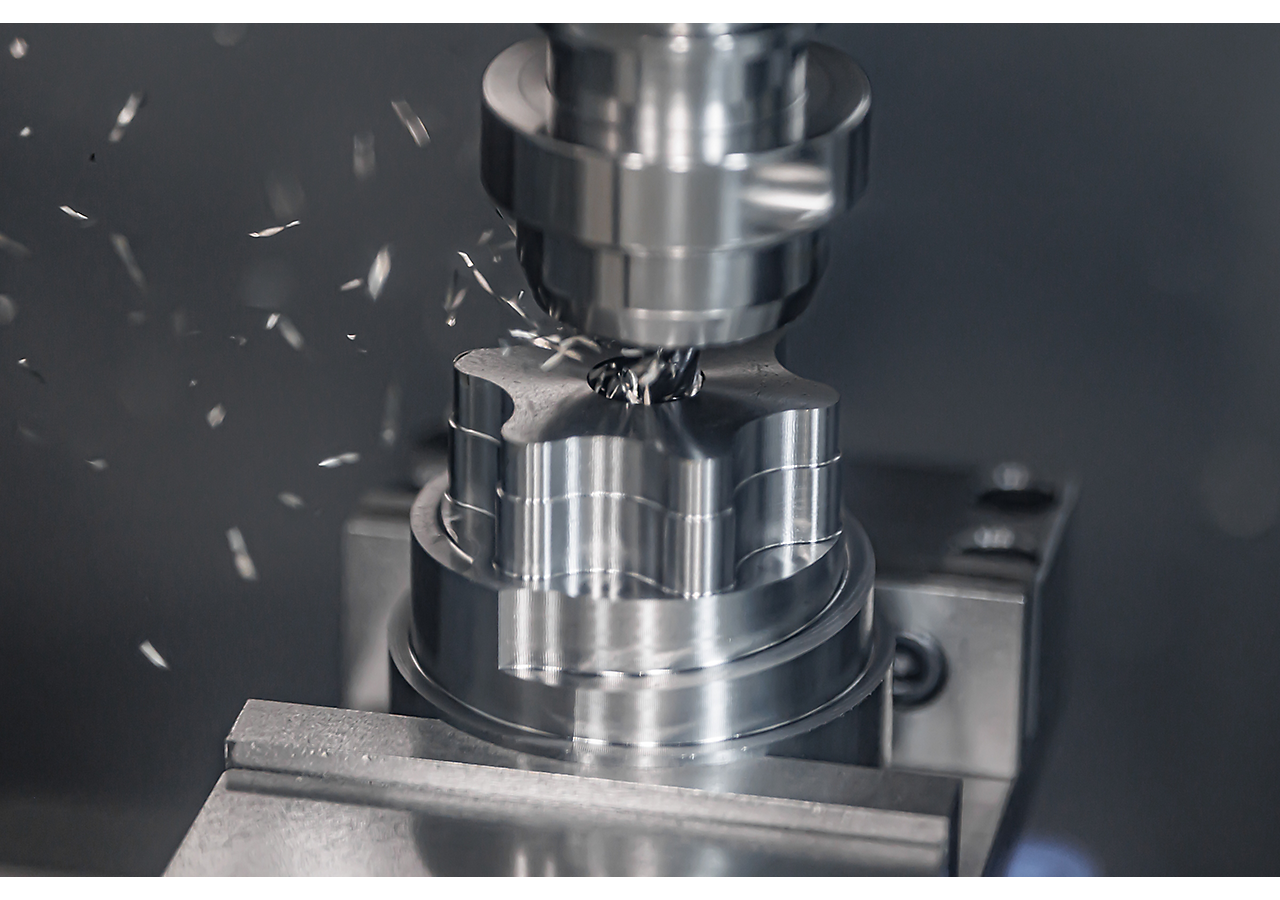

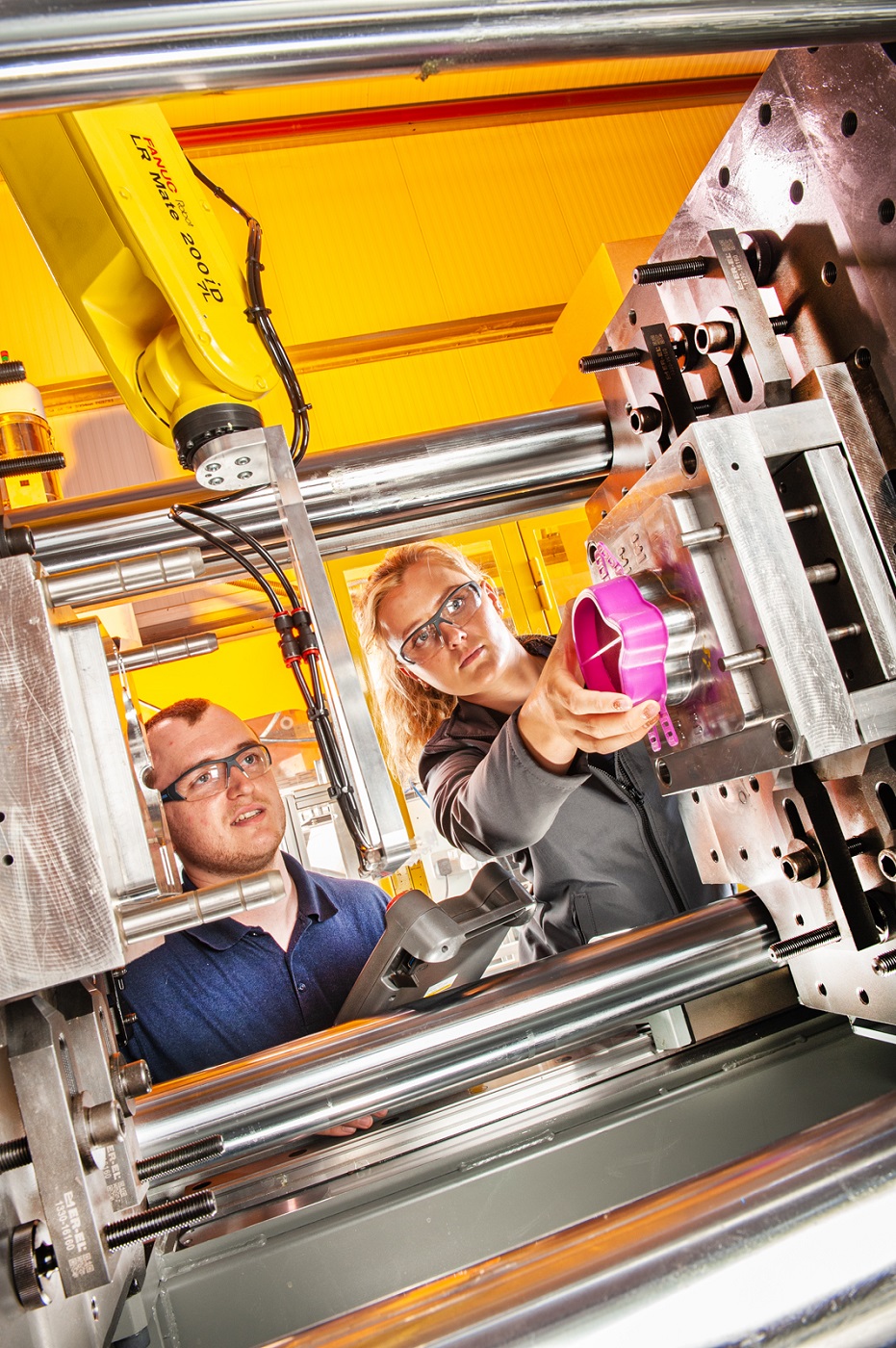

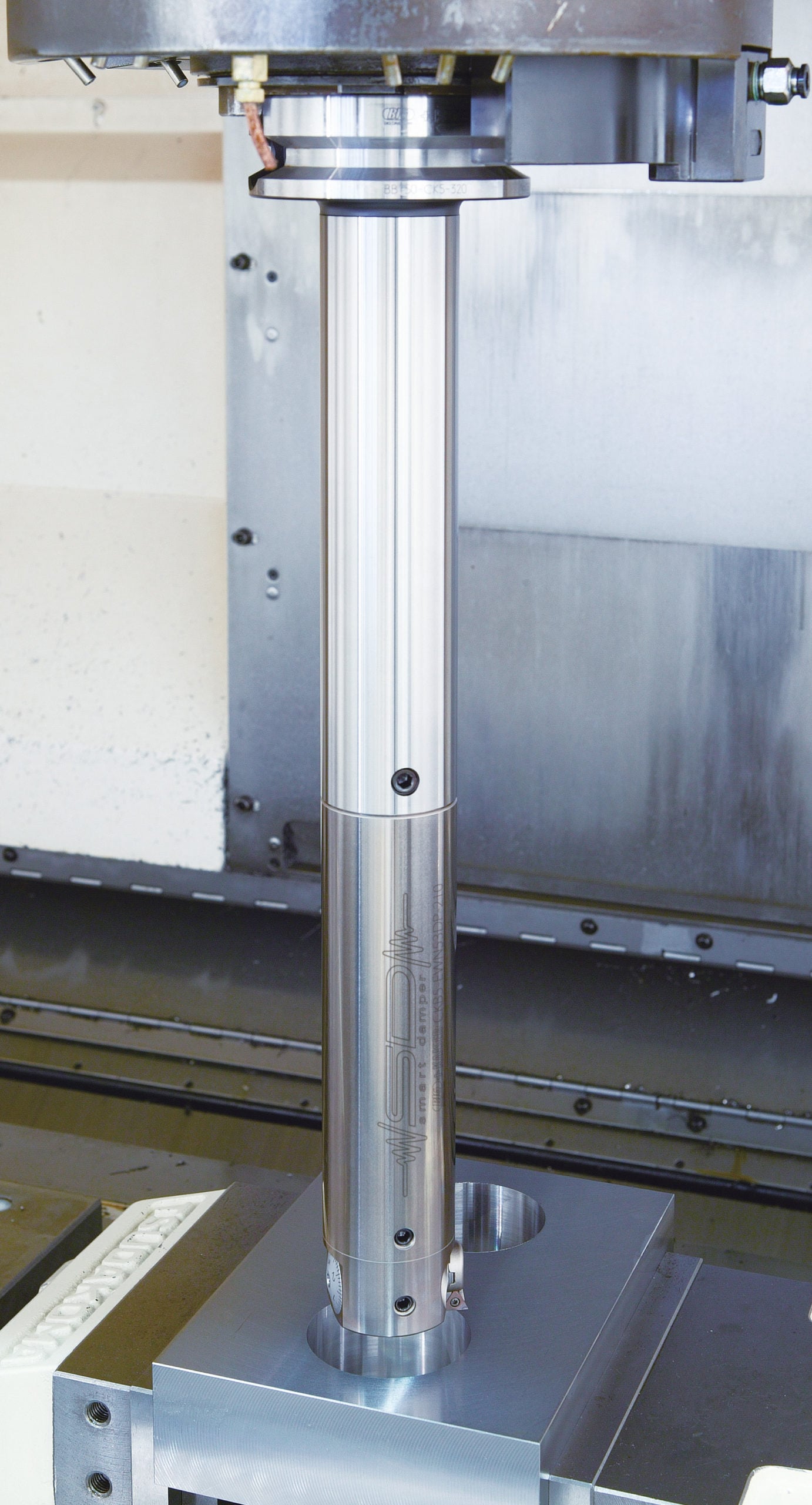

In today’s Technical Corner Ben Morgan from specialist tooling supplier ITC tells us about their BIG KAISER range of products. As Joe Reynolds from MTDCNC discovers all BIG KAISER products are face & taper giving them the ultimate in dual contact performance. As BIG KAISER manufacture the gauge that face & taper spindles are made to ensure that their products are the truest on the market. Their high-power HNC milling chucks are precision ground and balanced for high-speed machining and very rigid for heavy cutting giving security against pullout. BIG KAISER collet chucks have a guaranteed concentricity at the collet nose of less than 0.001 and less than 0.003µ at 4xD and are available for all machine tool spindle systems. Clamping sizes range from 3mm -32mm in various lengths, and collects are available for axial or through coolant systems. The MEGA Synchro Tapping system is perfect for high-performance rigid tapping on CNC machines. It improves thread quality and tool life by reducing thrust loads caused by synchronisation errors by up to 90%. BIG KAISER – big benefits.