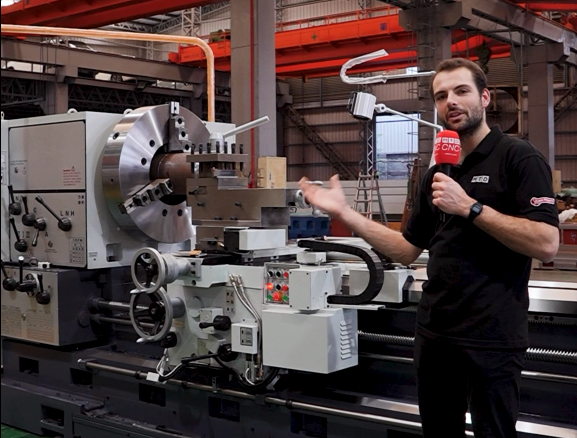

Posthumus, a Dutch manufacturing company, has made significant strides in long-part machining with the introduction of the MYDAY SGF 4-Axis Long-Bed Heavy-Duty Lathe. This new equipment is set to transform the company’s capabilities, enabling them to machine oversized components with greater efficiency and precision.

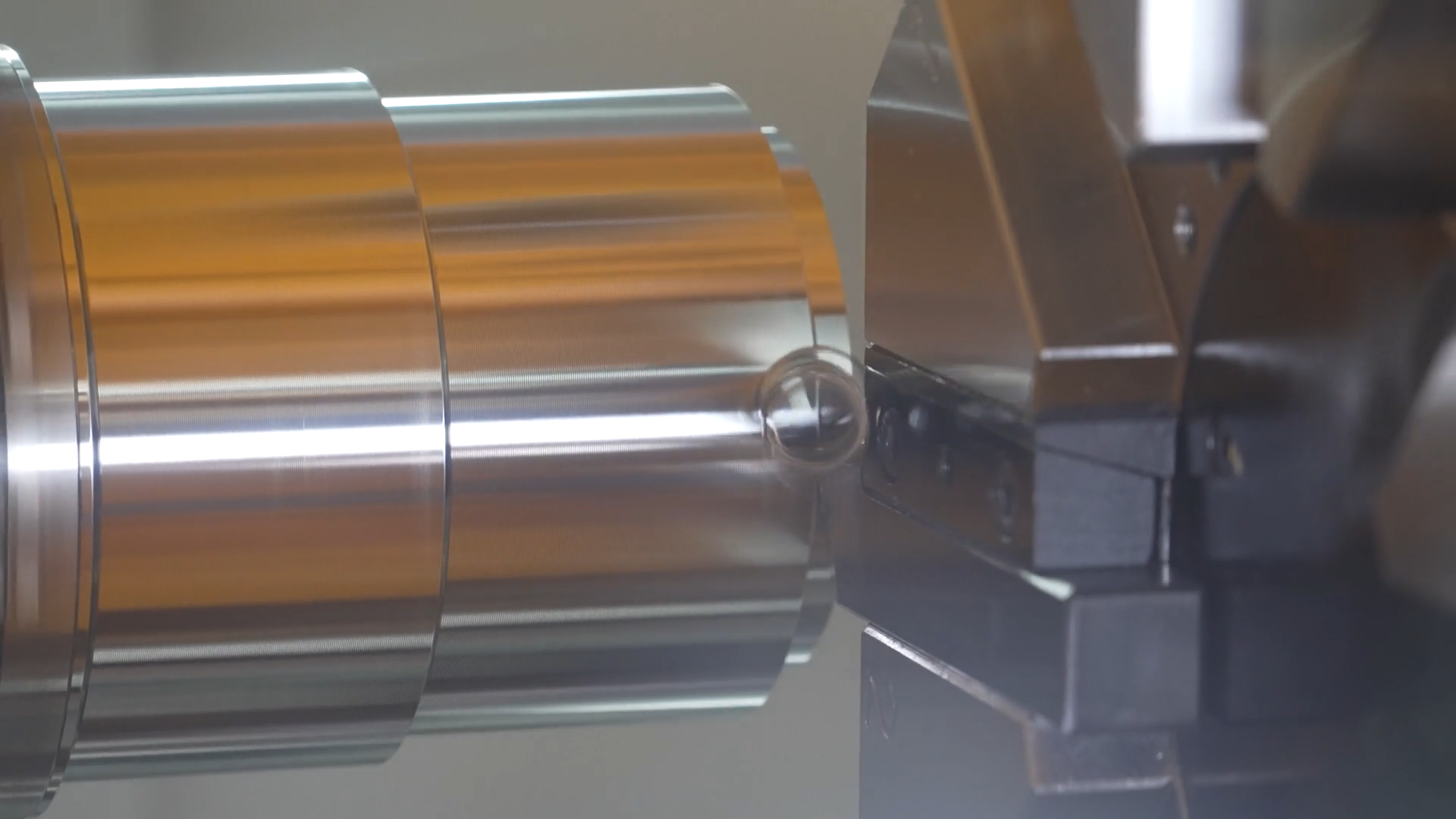

With a massive capacity of handling workpieces up to 2250mm in diameter and 10 meters in length, the MYDAY lathe is designed to accommodate the demands of heavy-duty machining. Its innovative 4-guideway design provides rock-solid rigidity, allowing for precise operations even for extended components that require turning past the center.

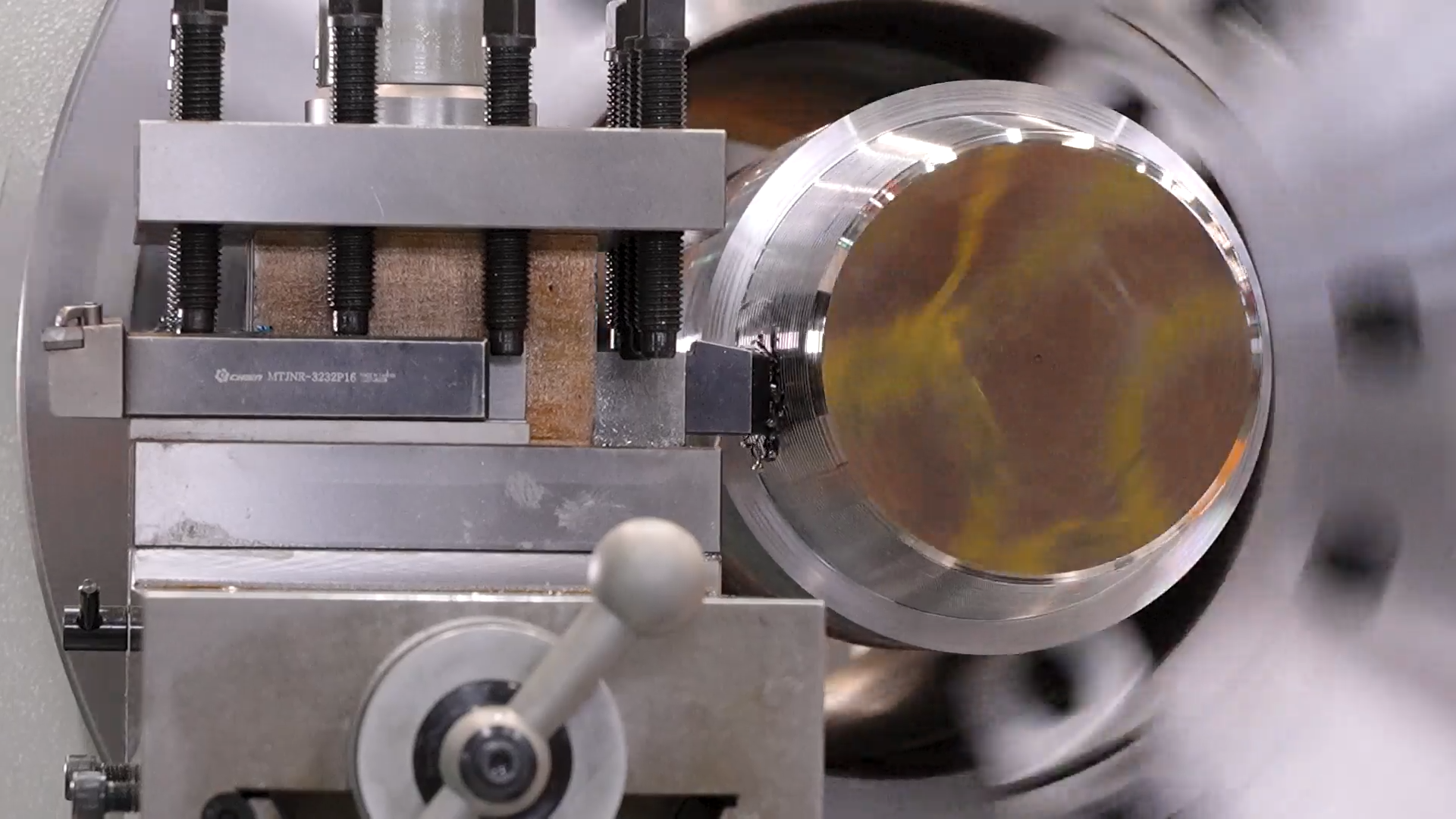

The machine’s operator-friendly features include a Siemens control system and a custom 8-jaw chuck, making it adept at handling complex shapes. Furthermore, the integration of quick-change Capto tooling and a chip conveyor enhances operational efficiency by minimizing downtime.

This upgrade promises immediate production readiness and stability for high-volume machining tasks. As a result, Posthumus has reported an increase in inquiries from large-part customers, unlocking new business opportunities in the process.

Johan Cats, a representative at Posthumus, remarked that the MYDAY SGF lathe truly realizes the potential of long-part machining for the company. With this advancement, Posthumus is poised to set new standards in the industry.

Posthumus continues to solidify its status as a leader in the manufacturing sector by adopting cutting-edge machinery that addresses the growing demand for oversized machining solutions.