This laser-wire 3D printer is changing the rules of metal manufacturing.

By Arthur Field

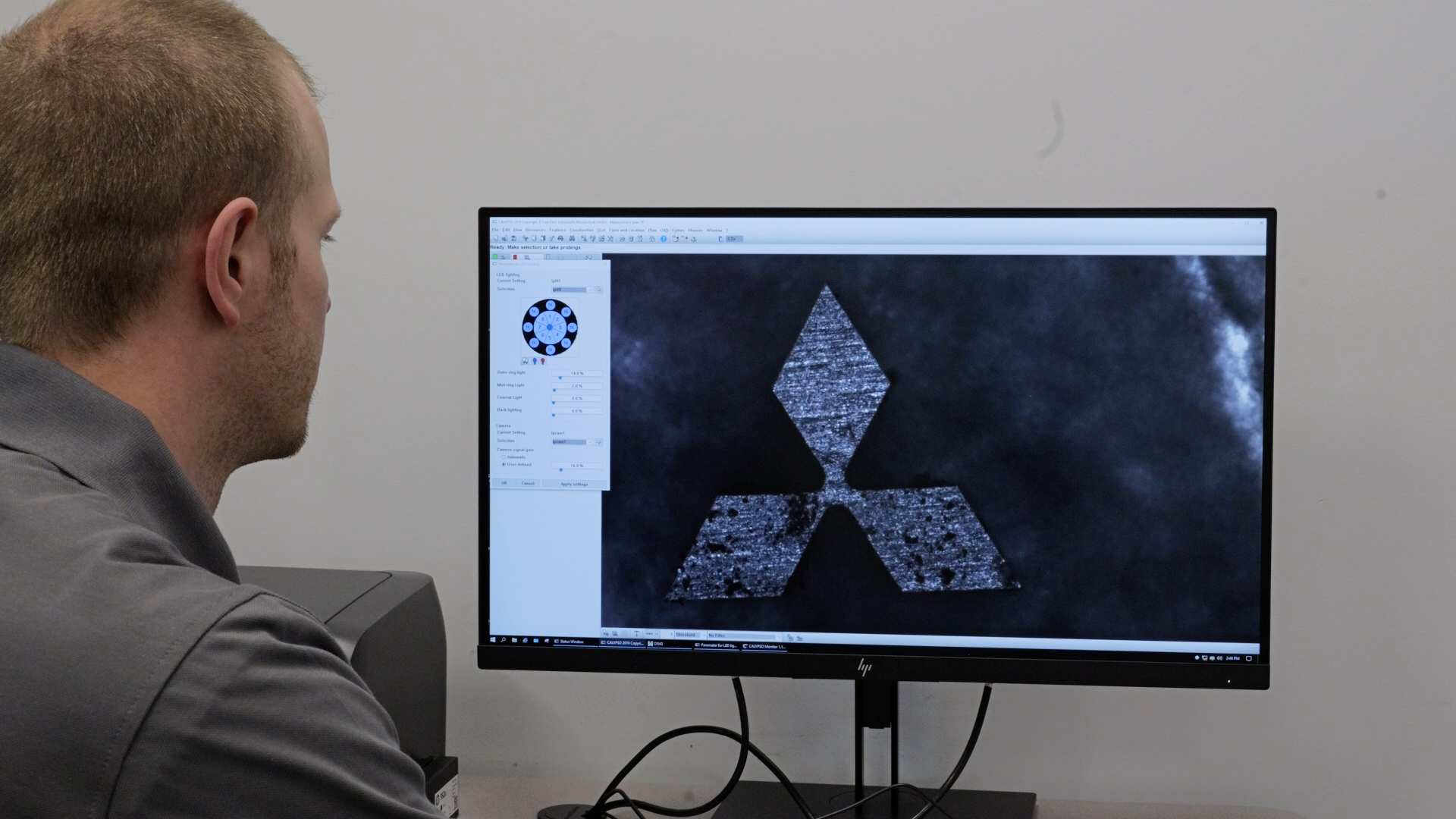

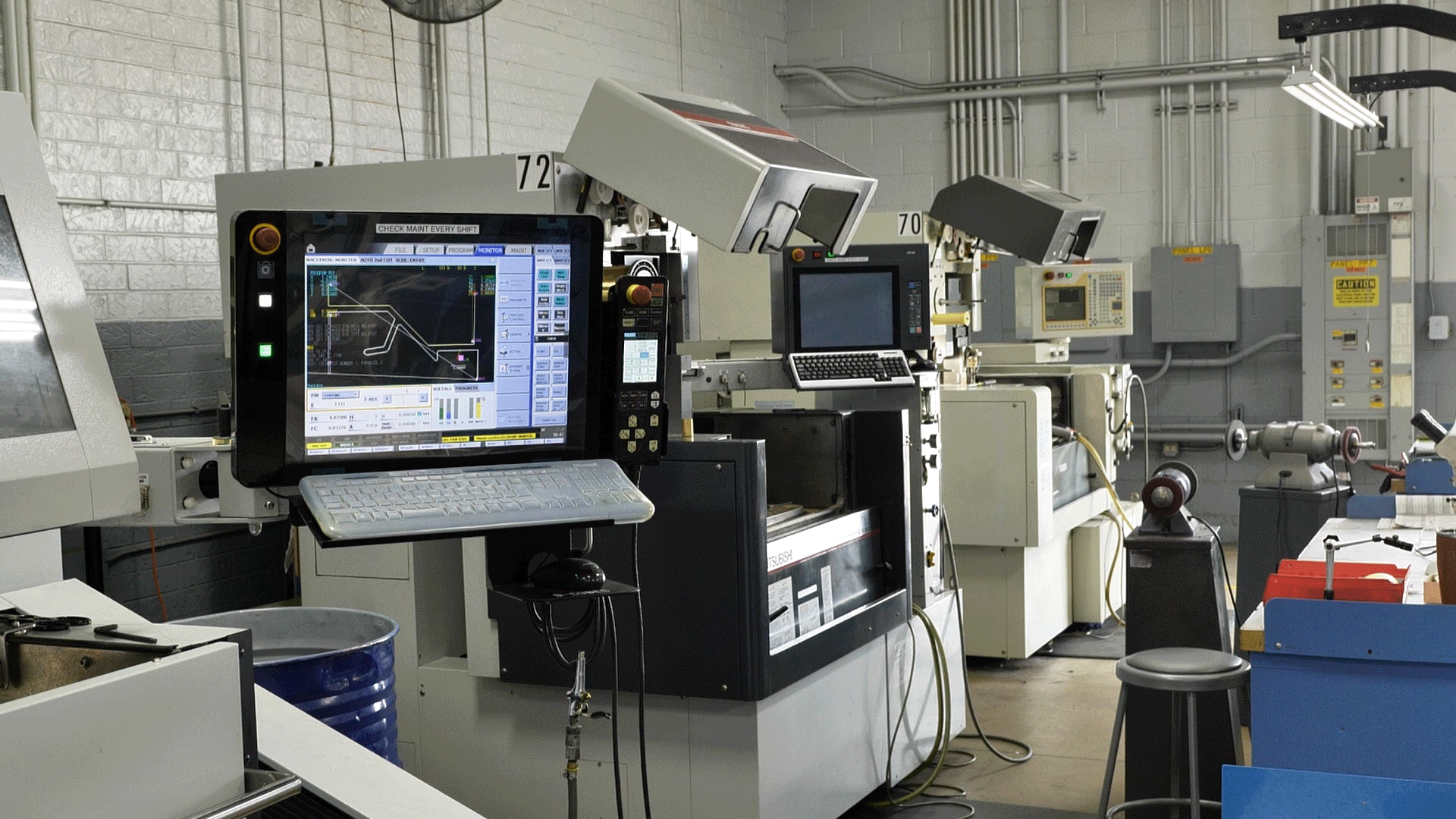

Forget powder. Forget long lead times. The Mitsubishi AZ600 from MC Machinery uses wire-fed laser DED to 3D print metal parts with incredible consistency.

Why is it a game-changer?

The AZ600 prints complex metal parts using pure wire — no coatings, no flux — making it a safer, cleaner alternative to powder-based systems. It drastically reduces porosity, waste, and post-processing. Perfect for mold repairs, exotic alloys, impellers, and one-off legacy parts, it also eliminates long tooling lead times thanks to its fully digital workflow. Best of all – you can build, machine, and even switch materials all in one seamless process.

Cladding, repairs, prototypes — all done with repeatable precision and five-axis flexibility. This is additive manufacturing evolved. Tune in with Arthur Field of MTDCNC and John Petti of MC Machinery Systems to learn more.