Founded in 2014, Shropshire Precision Engineering is an ambitious start up venture that deploys its skill set across a host of industry sectors that include the aerospace, power generation, automation, general engineering, motorsport and green energy markets. With a large percentage of the company’s work in the automotive industry, the Shrewsbury based company is employing Tungaloy cutting tools.

Utilising software packages like FeatureCAM with the latest Siemens CNC controls on its CNC machine tools, the small business manufactures anything from simple to complex parts in quantities from one-offs through to small batch production. Company Director Mr Robin Chisnell says: “We are confident that we can machine pretty much anything. Over the last three years we’ve invested heavily in the machine tools and the measuring equipment. We have also invested in the Tungaloy high-feed cutter, which is a great tool for our business.”

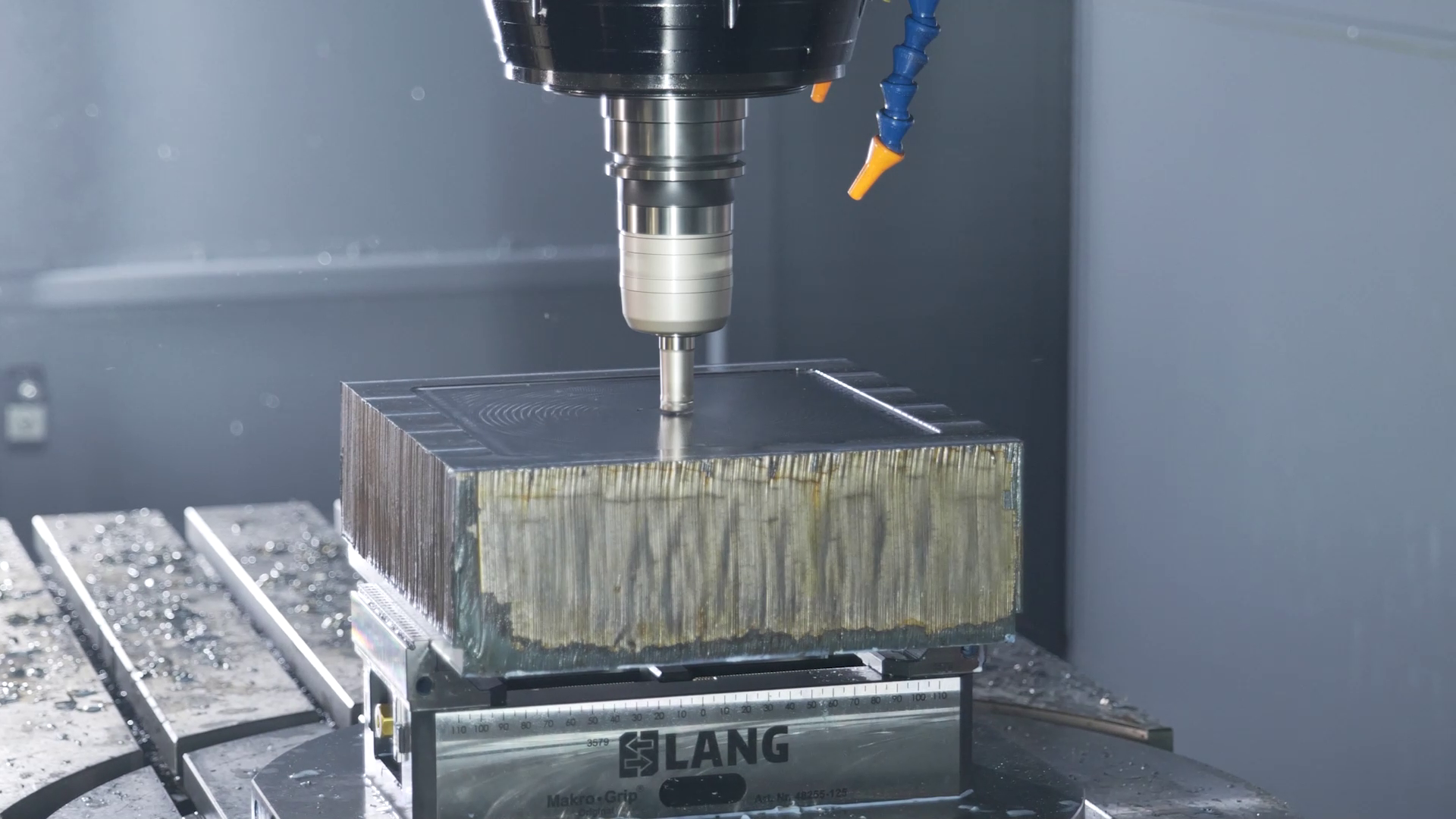

“We have used quite a few high-feed tools in the last few years and the Tungaloy tool has basically outstripped the others. The design of the tool is amazing really. How they have managed to fit 5 tips in a 25mm diameter cutter is amazing. This gives a much higher feed rate and the tool life is amazing too. We are at a stage where we are changing the tips in the morning and they are lasting all day. We can come in the next day, turn the inserts before they get damaged and they will run all-day again with no issues at all.”

Looking at a particular job, Mr Chisnell is asked why a high-feed cutter over a face-mill, he responds: “The traditional approach would be to machine this feature in a single pass with a 45 degree milling cutter, but we have tried to adopt this approach and the component rotates or moves within the vice regardless of what jaws we selected, so we went for a high-feed strategy and we now have a very repeatable, reliable process. This makes a 25mm diameter high-feed cutter the right tool for the job. The tool is running at 0.6mm per tooth at a 1.1mm depth of cut, so it’s just a little shy of 6m/min. We machine this engine component in batches of 150 – 200, so speed and quality of component is of the upmost importance.”

“This is our first trial with Tungaloy and it has worked very well. We will now be looking at tooling for our lathes as well as the milling. We will definitely start switching to Tungaloy. The long term aim of the company is automation, but we must have reliable tooling, especially if we are planning to run overnight production lights-out. We will need cutting tools capable of meeting this need.”