6

0

Supplier

Iscar

Clapgate Lane, Birmingham, B32 3DE, Engalnd

0121 422 8585

About

Now in its 40th year in the U.K., ISCAR has successfully developed a major presence in the metalworking industry by helping customers to improve their productivity through the application of our innovative leading edge technologies and unique cutting tools. ISCAR's unique headquarters building is conveniently located in the South West outskirts of Birmingham, close to the motorway network. From here, all sales and administration functions are coordinated. In the field, a team of over 50 engineers and over 200 distribution outlets provide on the spot support to customers. Training seminars are regularly conducted in our dedicated, state-of-the-art Training and Seminar Centre. Here a 90 seat auditorium, 450 square meter showroom and demonstration unit housing 4 CNC machines is used to provide top quality courses in the application of new cutting tool technologies. Specially tailored tooling is produced in-house in our new 800 square meter Integrated Design and Manufacturing Centre. ISCAR TOOLS, LIMITED has been certified to BS EN ISO 9001 since 1994 and Investors in People standards since 1996. For additional information, please see our local site on the Internet at http://www.iscaruk.co.uk

Recent Podcasts

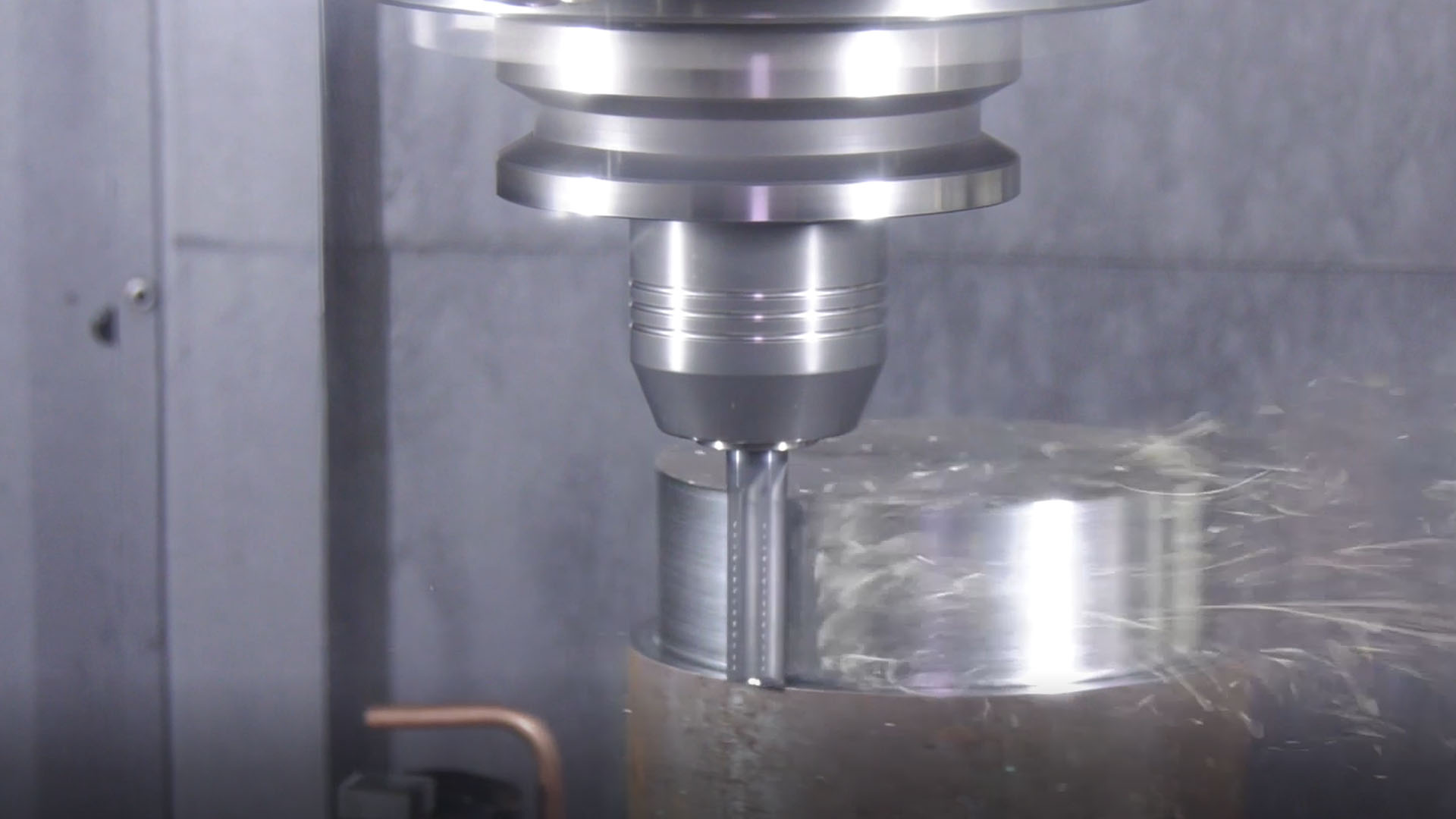

Insert evolution continues to take shape

The introduction of the ISCAR HELIMILL in the 1990s marked a significant milestone for milling tools. It revolutionised the design of milling tools with indexable inserts, establishing a new approach that would shape the industry for years to come. This breakthrough was achieved using a parallelogram-shaped carbide insert, featuring a helical cutting edge formed by the intersection of the insert’s helical side and shaped top surfaces. The HELIMILL concept offers several advantages. Firstly, the consistency of the rake and relief angles along the insert cutting edge when mounted on a tool reduces cutting force variations and ensures a smooth cutting

Innovation never stops

Where Innovation Never Stops! is the slogan that appears on the walls of the production facilities at ISCAR headquarters and has been synonymous with the company for several decades. The Covid-19 pandemic did not interrupt the innovation process, and between 2020-2021 ISCAR introduced the NEOLOGIQ marketing campaign comprised of advanced cutting tools and tooling solutions for modern metalworking. Significant changes in manufacturing, such as intensive digitising, the shift to electric drive in the automotive industry, and growing precise workpiece fabrication, have emerged with new demands for cutting tools. Notwithstanding, the accelerated pace of changes sharpens the demands and requires more

What We Do

Your partner for marketing, media, and events in manufacturing.

Join Thousands of Professionals Staying Ahead with MTD

Sign up to receive the latest videos, insights, and exclusive content from the world of manufacturing