27 March 2025

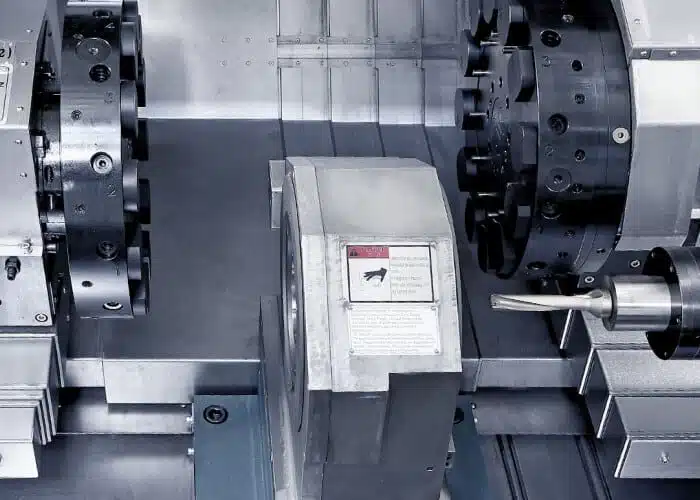

MULTI-SURFACE MILLING – 65NC

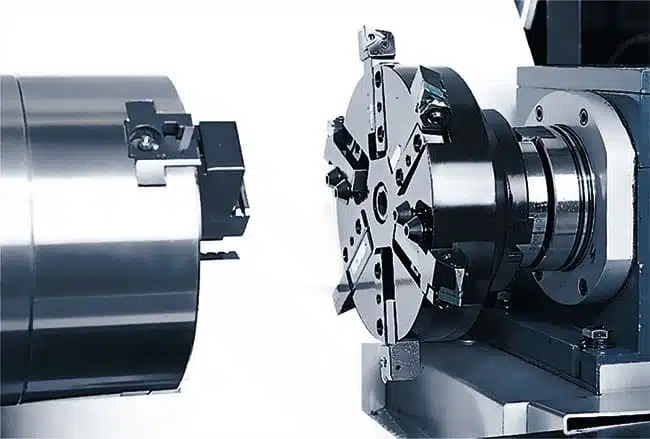

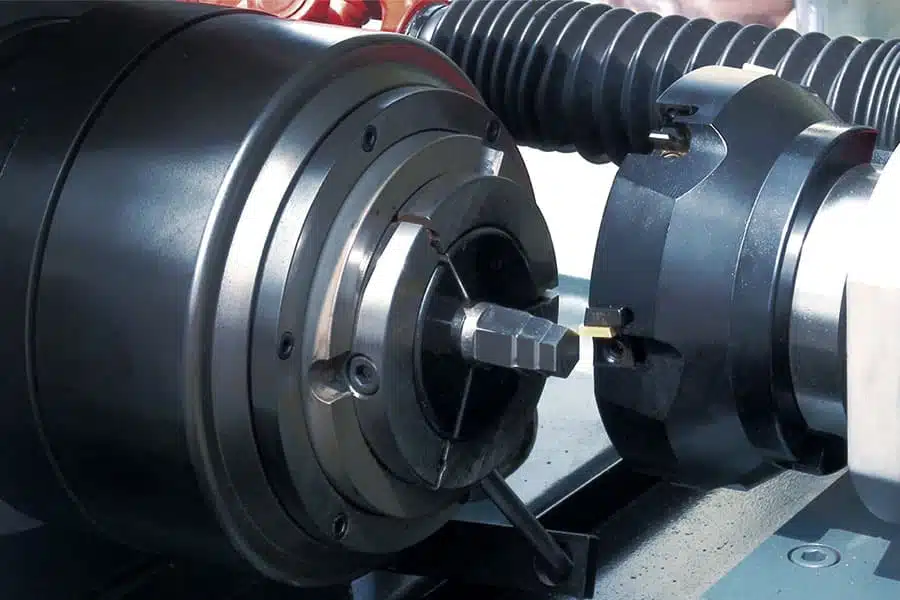

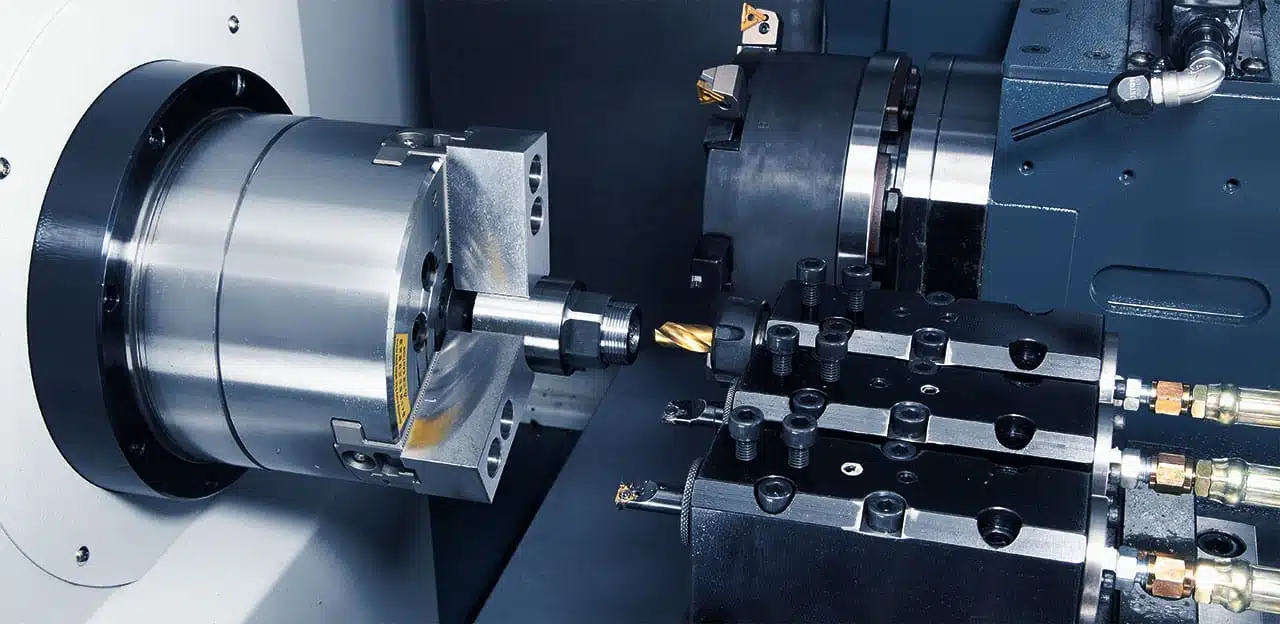

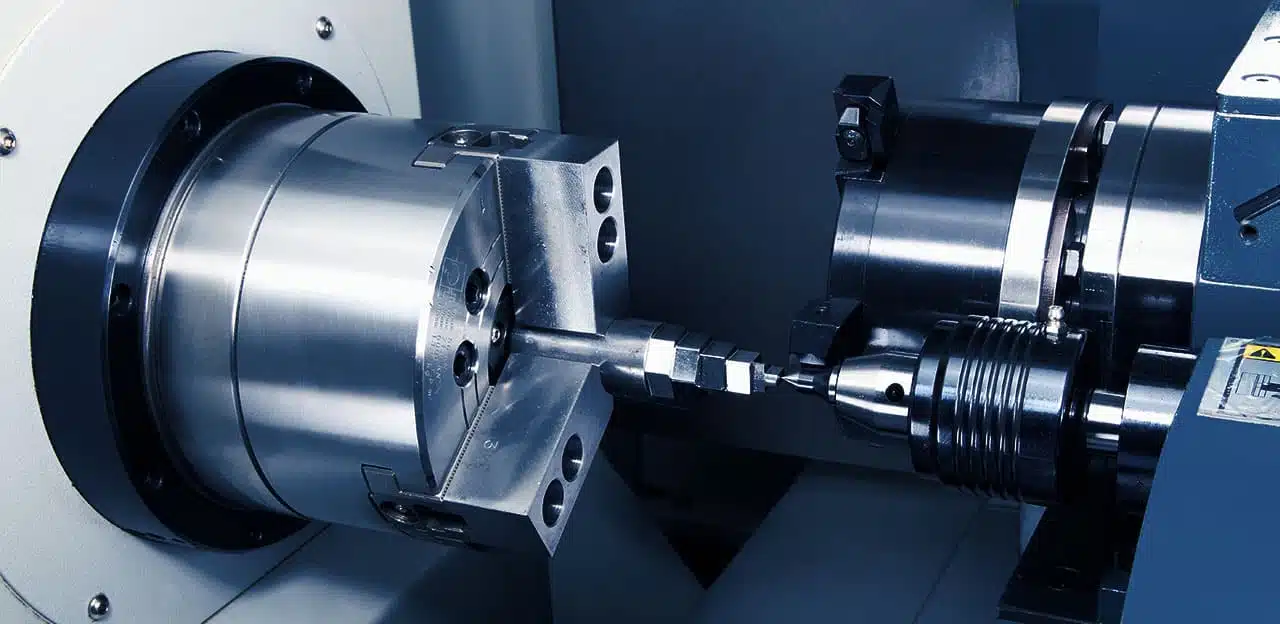

Unique machine design dedicated to Polygon turning.Rigid construction achieves high performance over a wide cutting range which includes an even number of polygons, eccentric and profile cutting as well as dual phase machining. Item Description Spindle Motor 7.5 kW Chuck Hydraulic 3 Jaws / Collet Chuck* Machine Control Fanuc / Syntec Recommended Option Tailstock / Collet Chuck / Auto-Loading / Unloading System Machine Weight 2500 kg Standard Option Standard Cutter Head Cutter Head Inverter Tailstock Half Guard Or Full Guard Automation Part Loader System Hydraulic Power Chuck Central Position Cutting Standard Rear Locator Particular Rear Locator Attached Jaws Linear Encoder

View Product