In 2015, Wesbart decided to carry out a full review all their products and manufacturing process which involved looking at every aspect of the production process to help improve productivity and reduce costs.

David Patey, Sales Executive at Wesbart tells us the process Wesbart carried out.

Over the last five years we have redesigned our products, re-branded the company, including a new website and catalogue, changed our packaging to offer an easily recyclable solution and set up an in-house anodising process plant. In total the company has invested over £1.7million.

One of the main processes which required investment was the folding process. All aluminium and stainless steel parts are folded using a manual system with an operator. Due to the increase in orders it was necessary to use subcontractors to meet demand. Our production runs could range from 150 parts up to 5,000+. The solution was to look at an automated folding process, many of which are available. We started to look to see what systems were available however we noticed the bending cells on the market were either too large for very big components or designed for much smaller parts all of which took up a lot of valuable floor space.

We carried out some testing of various options and found the parts would need to be fed into the cell on a conveyor system.

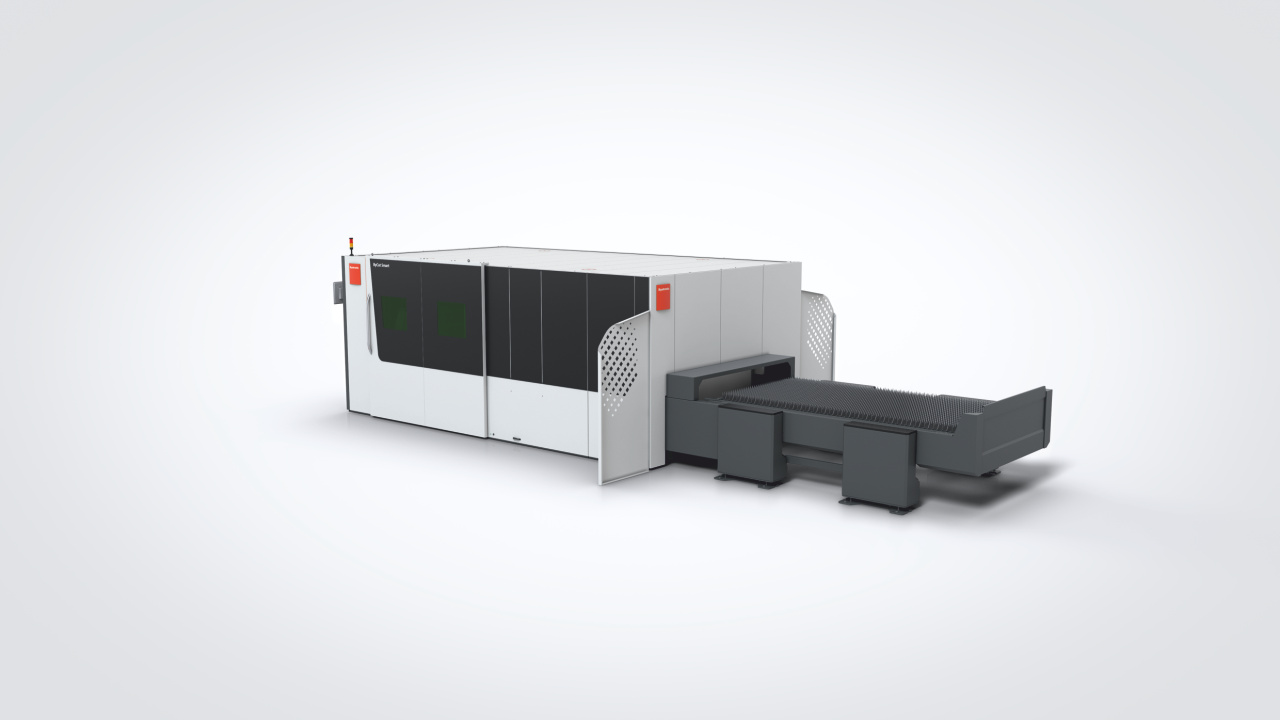

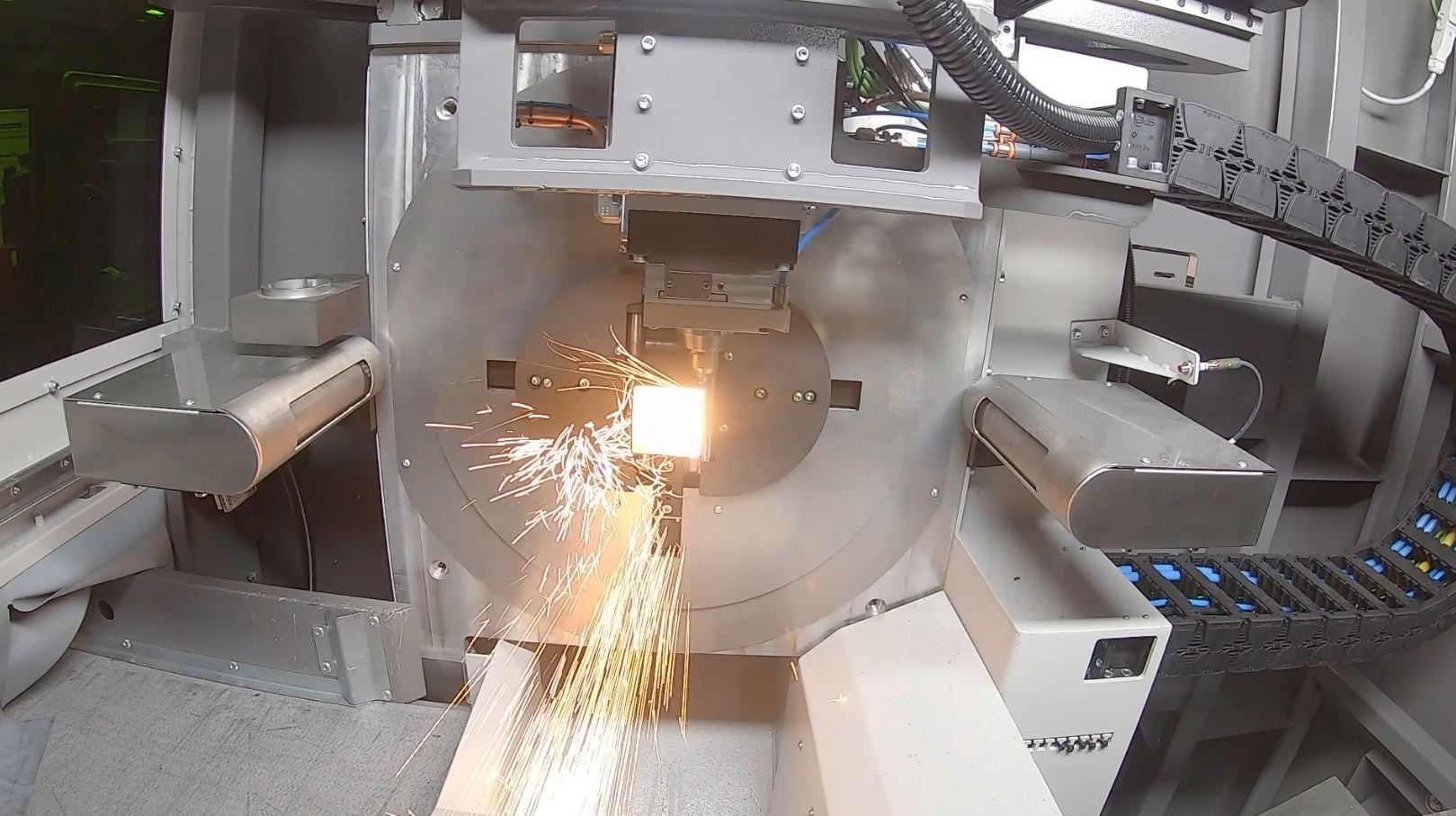

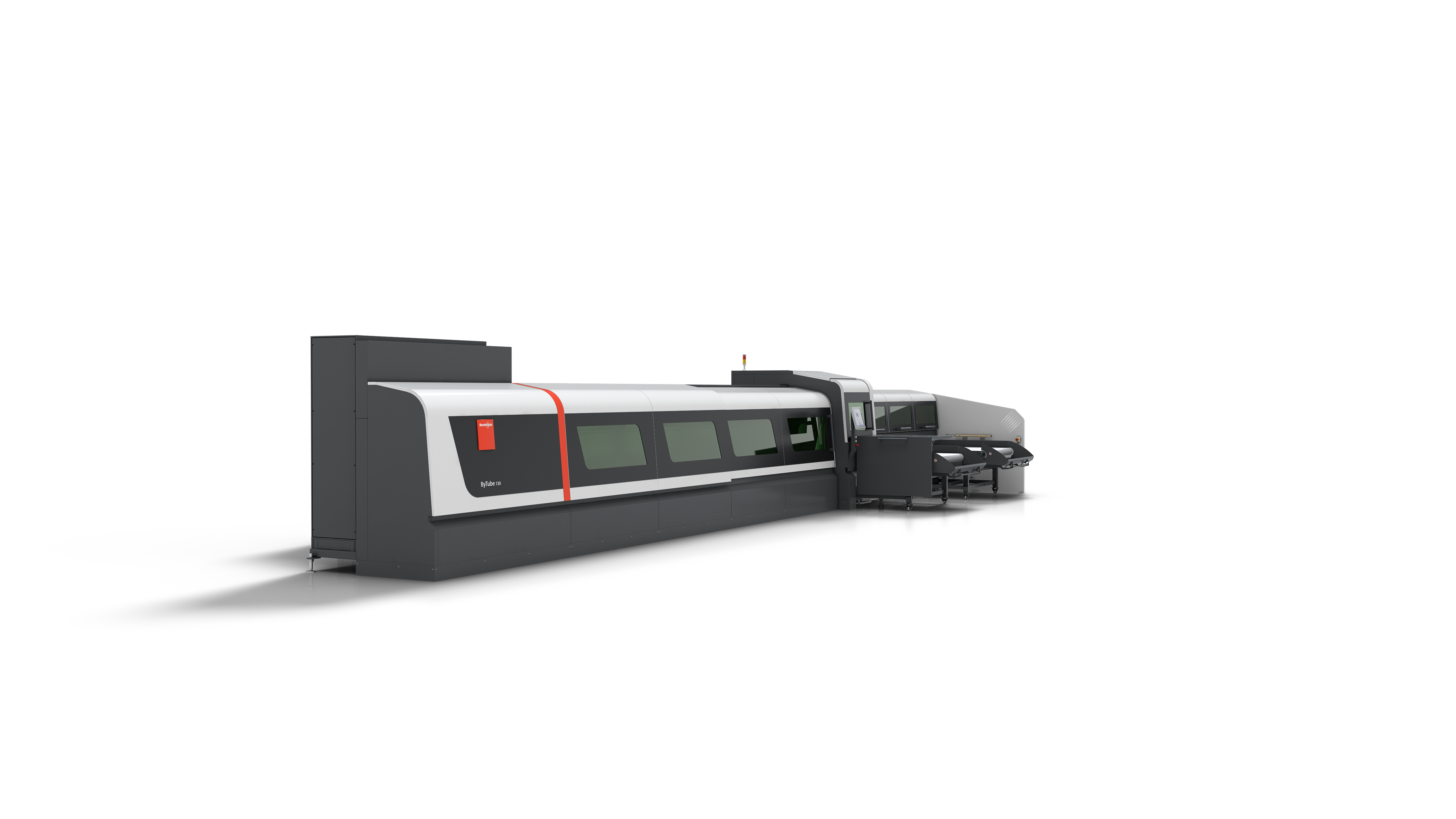

We contacted a locally based robot integration company (ICS Robotics and Automation) to work with Bystronic and develop a suitable system. We chose to use the KUKA robots and the Xpert 40 pressbrake, due to their small footprint. ICS designed a bespoke space saving setup using three KUKA robots, one operating each pressbrake with another feeding the parts from the conveyors. A camera system was included to identify the parts and confirm they have been placed on the conveyor correctly.

The system was delivered in January 2021 and has already shown a great deal of potential. The Bystronic pressbrakes are incredibly quick and reliable. The user interface is very easy to operate and helps with robot programming for our products. The space saving design helps free up additional space on the factory floor.

With the investment made in the bending cell we hope to continue to remain a market leader based on the quality, price and lead time of our products and allow us to enter new markets.