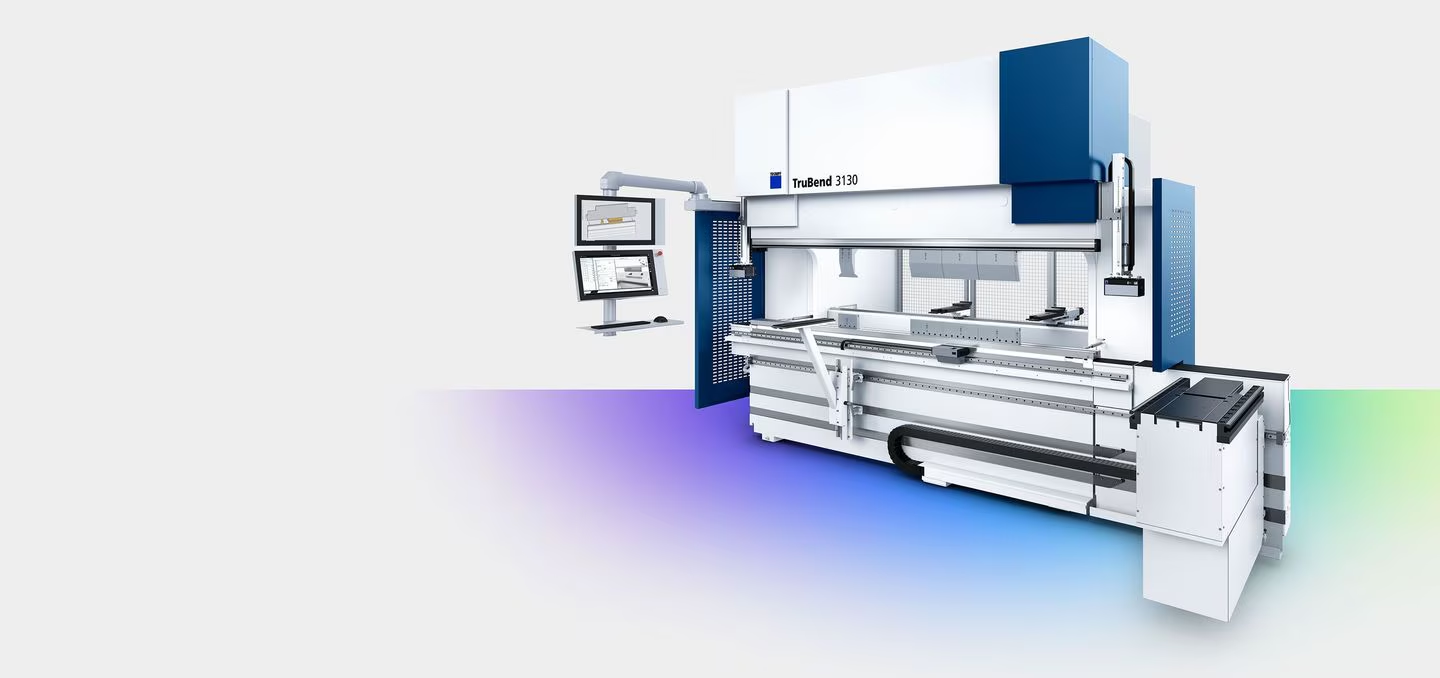

TRUMPF’s New TruBend 3000 Series Cuts Throughput Time by Up to 40%!

By Ashutosh Arora

TRUMPF has introduced the latest generation of its TruBend 3000 series bending machines, delivering a significant performance boost with an estimated 40% reduction in throughput time compared to previous models. Engineered to meet the needs of small and medium-sized manufacturers, contract fabricators, and production shops, the new TruBend 3000 series combines power, precision, safety, and digital connectivity in a single, versatile press brake platform.

Depending on the model, the new TruBend 3000 offers press forces ranging from 93 to 253.5 tons and bending lengths between 6.5 and 13 feet, enabling users to handle a broad spectrum of part sizes and material thicknesses. TRUMPF has focused heavily on precision improvements in this updated series, integrating the ACB Laser automatic angle measuring system to deliver consistent, high-quality results from the very first part. The ACB Laser utilizes a camera and laser sensors to measure the bend angle before each operation. If the angle deviates from the value specified in the software, the machine automatically adjusts the press beam to correct the error — even when dealing with material batch variations. This level of automation not only ensures excellent repeatability but also reduces scrap and downstream rework.

Enhanced productivity is further supported by TRUMPF’s TecZone Bend offline programming software. This solution allows operators to program new jobs while the machine is actively bending parts, significantly improving overall efficiency. TecZone Bend streamlines the programming workflow with intuitive controls — users simply upload a 2D or 3D model, and within moments, the software automatically generates the optimal bending sequence and tool selection, complete with collision detection. Operators can even perform programming directly from the machine’s touchpad, making job setup fast and accessible even for those with less programming experience.

Energy efficiency is another strong feature of the new series. With the speed-controlled On-Demand Servo Drive, the machine’s motor runs only during actual bending operations. This reduces energy consumption by up to 30% compared to traditional hydraulic drives, helping shops lower operating costs without compromising performance.

Safety remains a top priority, and the TruBend 3000 series incorporates TRUMPF’s advanced BendGuard protection system. Using matrix sensors and integrated cameras, BendGuard continuously monitors the work area. If an object — such as an operator’s hand — enters the danger zone, the machine immediately stops. The operator can quickly resume work by resetting the system using the foot switch, ensuring maximum protection while maintaining minimal interruption to production.

The TruBend 3000 series also supports TRUMPF’s digital ecosystem and can be seamlessly connected to other TRUMPF automation solutions, such as automated storage and smart factory modules. This makes it a future-ready choice for manufacturers looking to enhance efficiency, standardize production, and integrate into more sophisticated digital workflows.

Offering rapid throughput, high precision, reduced energy usage, and operator-focused safety features, the new TruBend 3000 series sets a new benchmark for performance and reliability in modern bending operations.