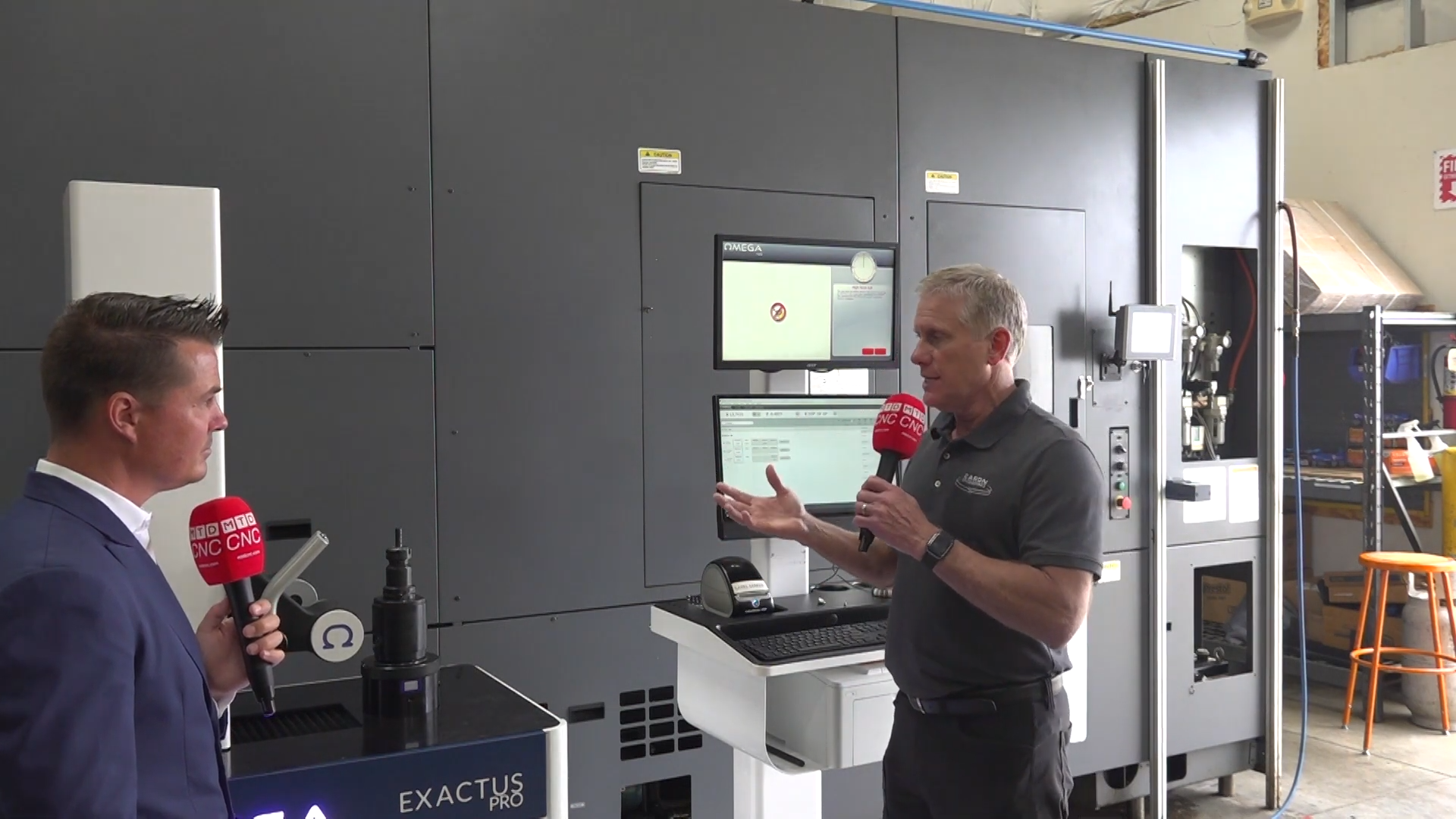

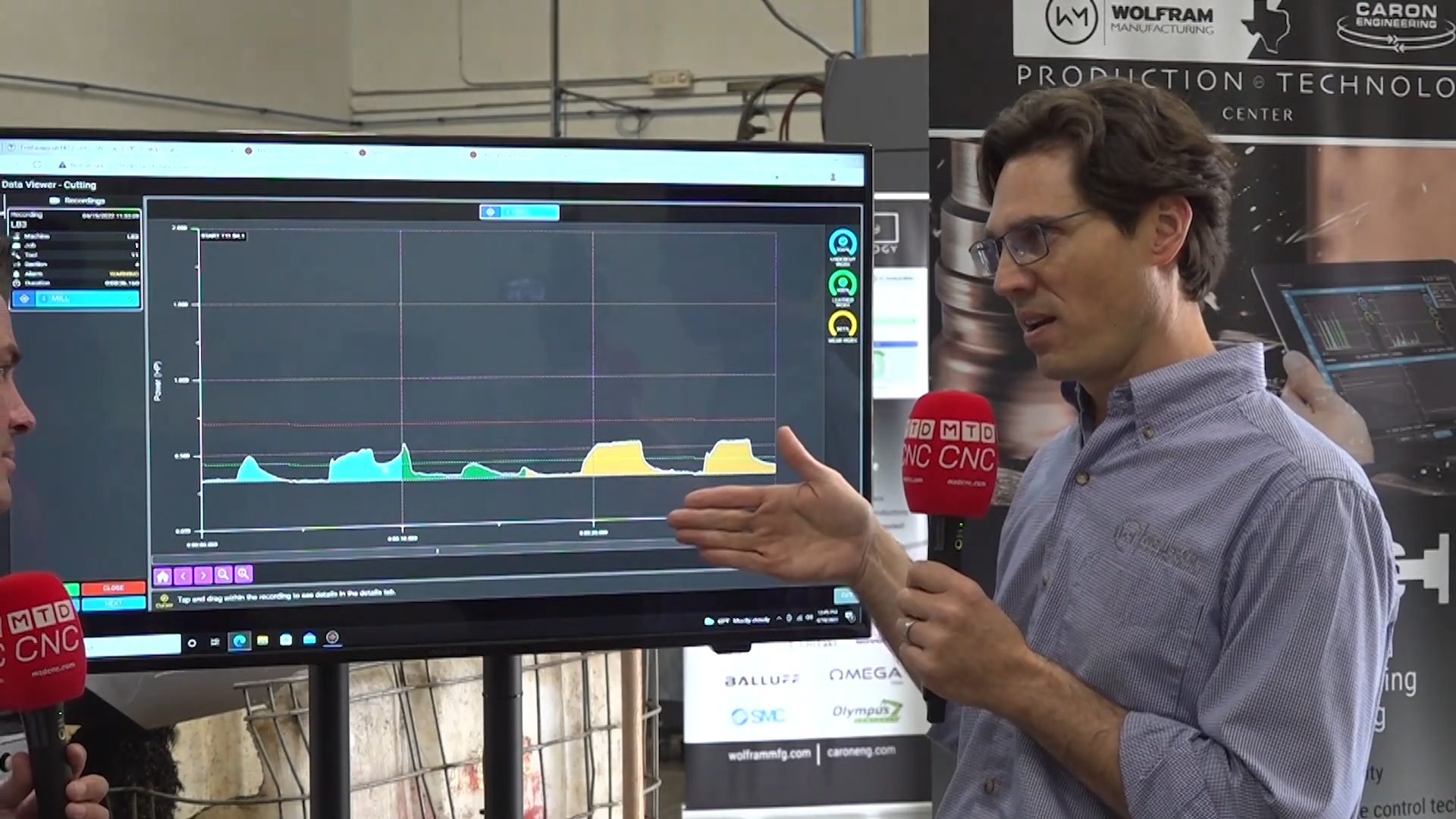

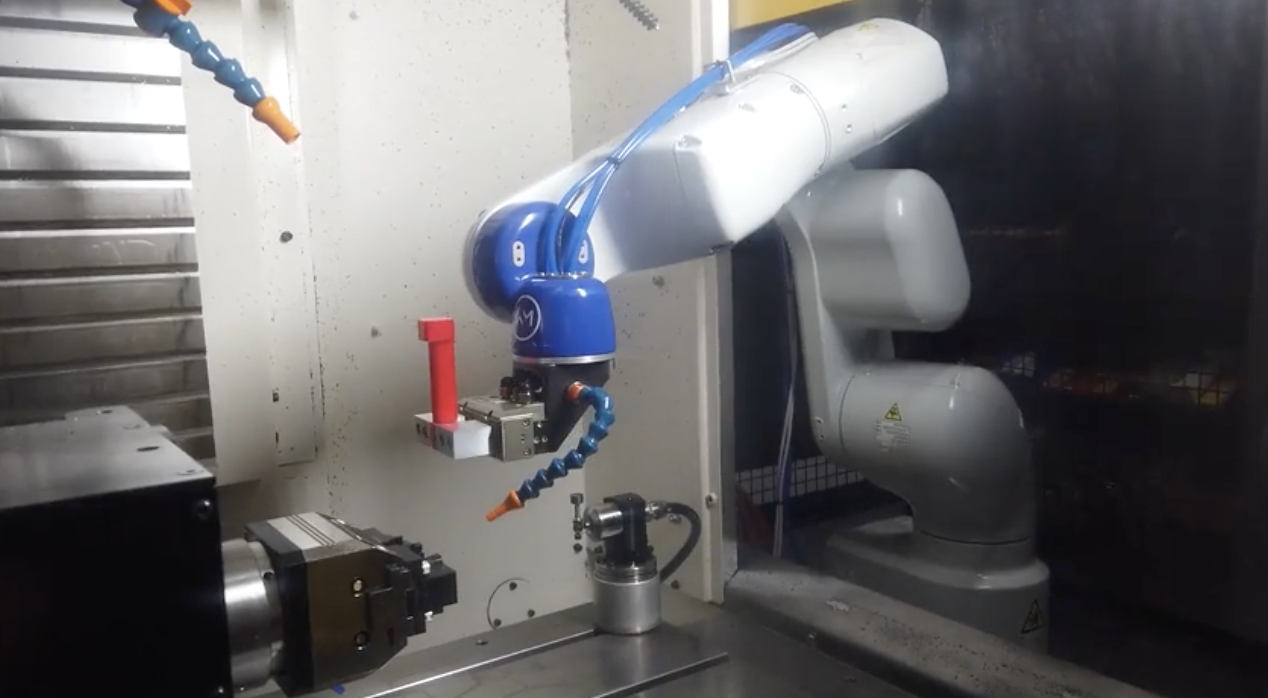

Rob Caron from Caron Engineering explains why Wolfram Manufacturing are using their DTect-IT CNC Sensor Analysis System on their bar feeders. DTect-IT combines high-precision sensor technology with advanced analysis capability to detect, in this case, vibration caused by bar whip and corrects anomalies occurring in the machining process preventing scrapped parts & reduced tool life. Using a multitude of sensor options, the user can monitor specific parameters to alarm and signal the CNC when irregularities are present. All data is recorded and accessible in the historical viewer to analyse and trend data over time. As MTDCNC’s Tony Gunn discovers Wolfram are also using another Caron Engineering product to help them run more efficiently, AutoComp, an automated tool wear compensation software package. AutoComp is a Windows based software application that eliminates human error by processing measurement data from almost any electronic gauging device, it reads the part measurement file and automatically calculates and updates tool offsets in the CNC control. No manual data entry needed! Two great products ideal for use in automation from Caron Engineering keeping the spindles turning at Wolfram Manufacturing.