Vargus BellShapeHolder System: The Ultimate Solution for Faster, More Accurate Threading in High-Volume Manufacturing

Vargus UK Ltd, a leading supplier of high-performance cutting tools and threading solutions, has announced the launch of its latest innovation for high-productivity environments: the BellShapeHolder System. Designed to significantly reduce threading cycle times while increasing tool life and accuracy, this new external threading solution sets a new benchmark in CNC turning performance.

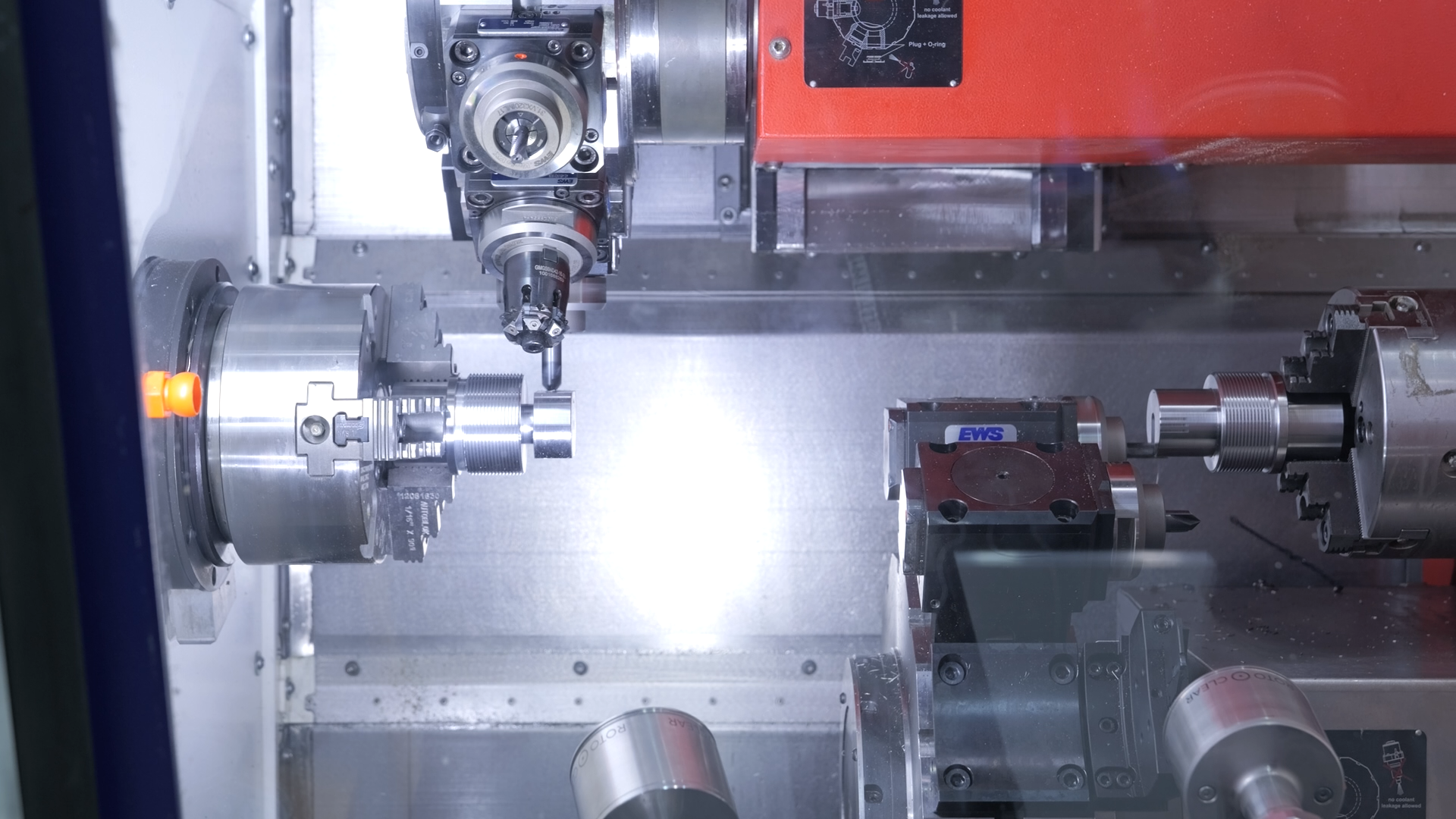

Developed for use in demanding production environments such as automotive, aerospace, and general subcontract manufacturing, the BellShapeHolder System is engineered to deliver faster threading, greater rigidity, and improved chip control — all while maintaining the high precision and repeatability Vargus is known for.

“Cycle time reduction and consistent part quality are non-negotiable in today’s competitive manufacturing world,” said a spokesperson for Vargus UK. “The BellShapeHolder System is our response to that challenge — it’s a fully optimised solution designed from the ground up for speed, accuracy, and reliability.”

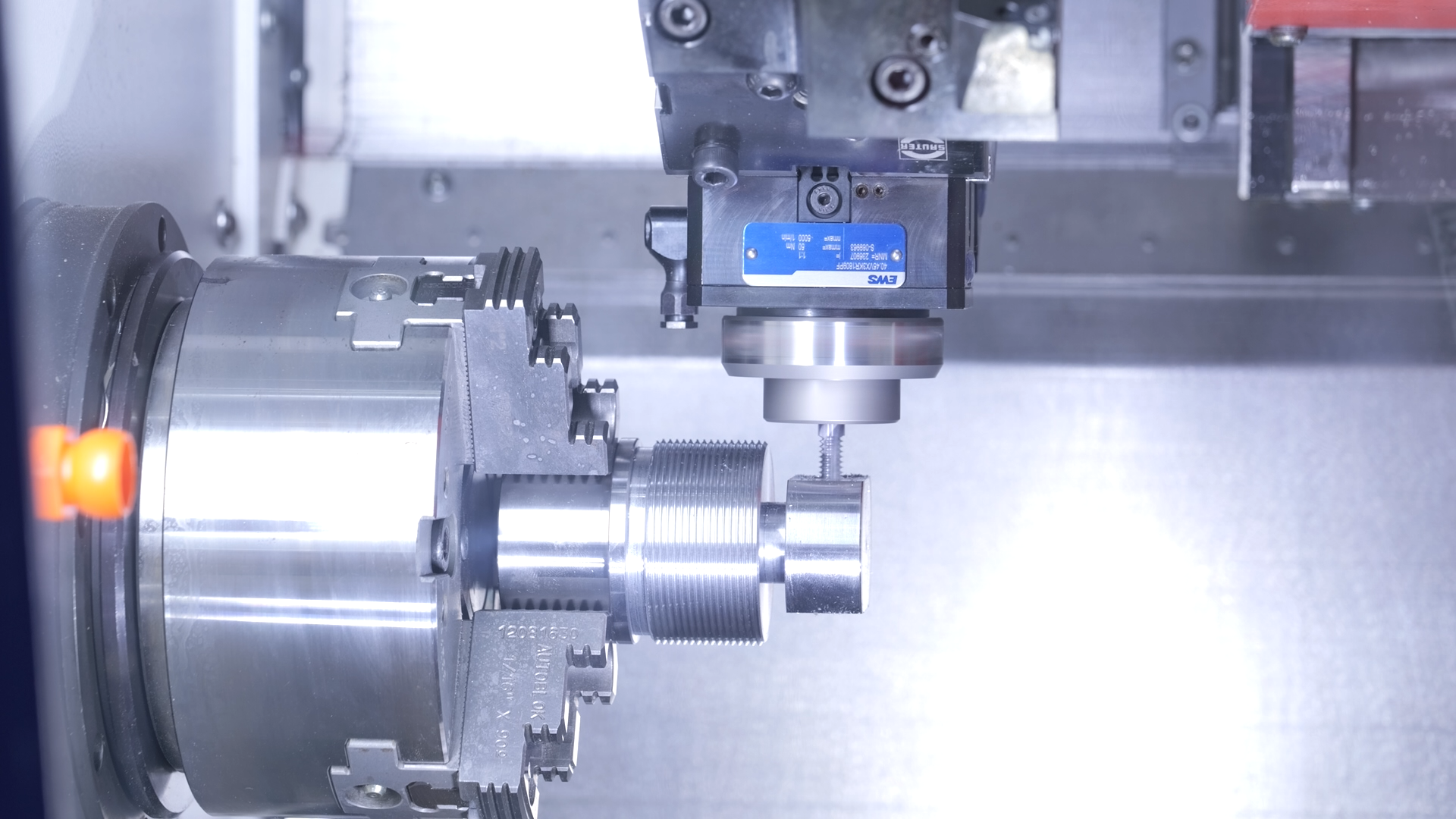

The system features a multi-flute toolholder that enables faster feed rates, contributing to a shorter overall cycle time. An enclosed holder design, coupled with a robust dovetail clamping mechanism, ensures the kind of rigidity and insert stability essential for high-accuracy threading. Vargus has also introduced a new range of specially developed inserts to complement the holder — including a combination insert that performs threading and chamfering in a single pass, reducing the need for tool changes and further boosting productivity.

One of the most notable features is the BellShapeHolder’s through-coolant system, which delivers coolant via 12 targeted outlets — three per insert — to dramatically improve chip evacuation and extend insert life. Each standard insert also offers two cutting edges, enhancing tool value and lowering per-part costs.

The BellShapeHolder System includes:

- Three standard threading inserts

- One combination insert for threading and chamfering

- High-pressure, through-coolant delivery

- Rigid dovetail clamping

Vargus UK is confident the BellShapeHolder will become a game-changer for manufacturers looking to optimise their threading processes.

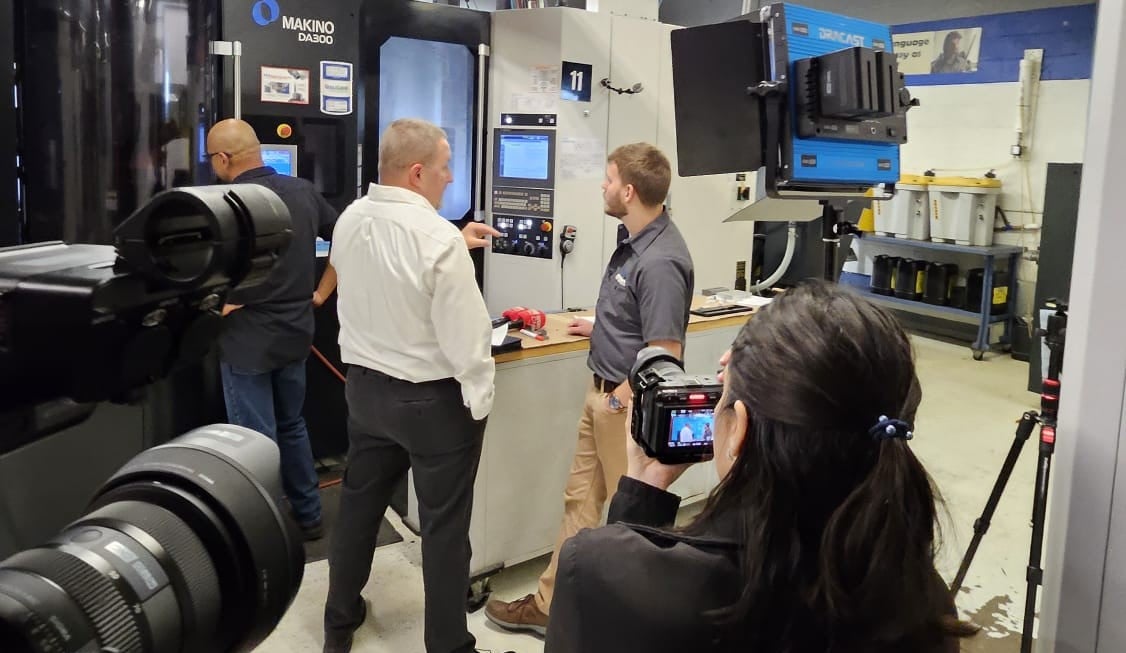

The new system is available now through Vargus UK’s national distribution network, with support and demonstrations available upon request.

For more information or to request a technical consultation, visit: www.vargusuk.co.uk