Tungaloy UK has now expanded its DoTwistBall profile milling line to include new insert radii. In addition to the renowned 04 (R4.0) style insert, Tungaloy has now added the 05 (R5.0) and 06 (R6.0) style inserts to the standard line. The expanded DoTwistBall incorporates an innovative design that allows two different types of inserts to fit the same shank, each dedicated to profiling and high feed application.

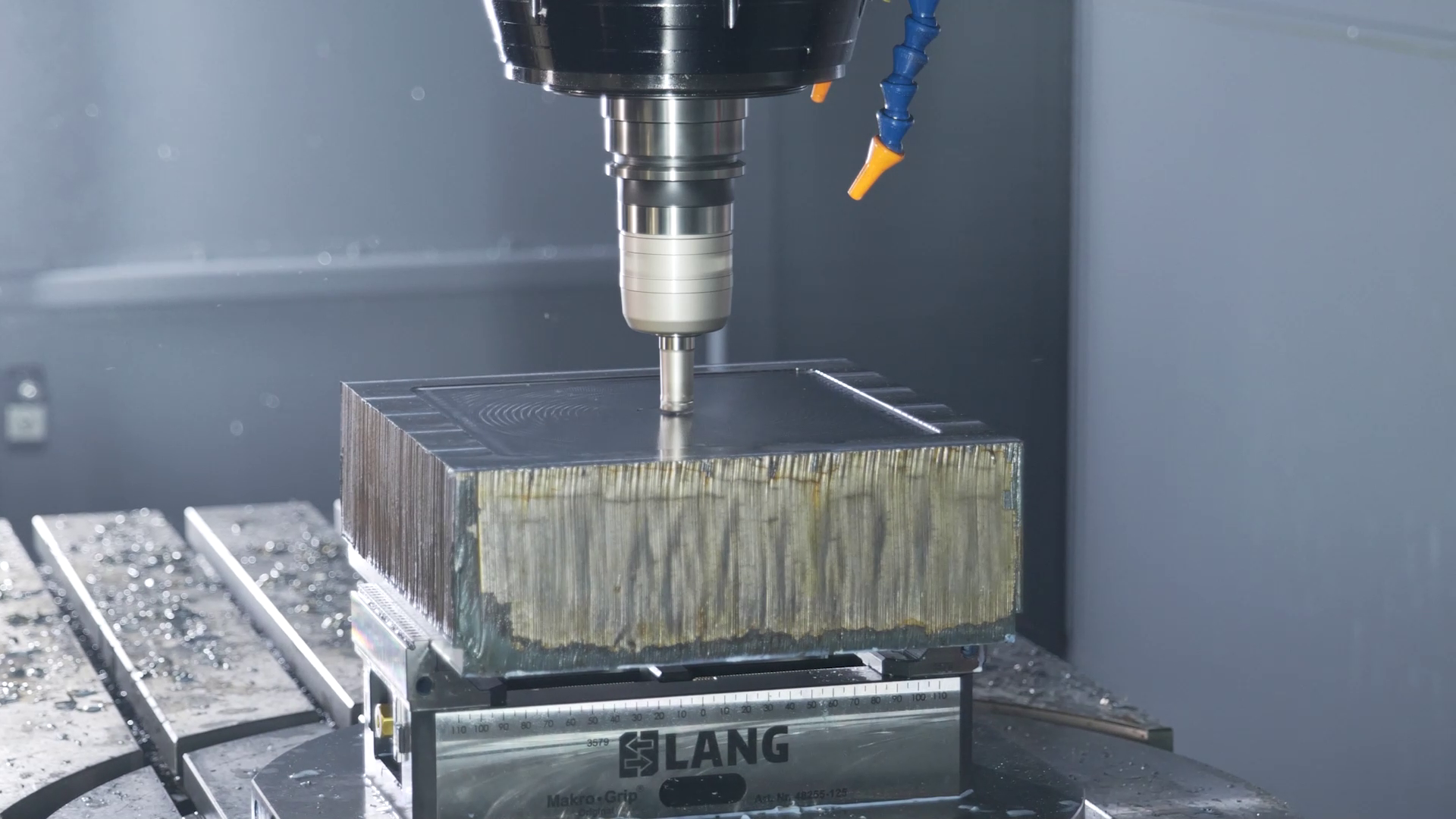

The insert is constructed in a helically twisted structure that fits the seat pocket constructed in a matching helical profile. This Twist Clamp system helps maximise insert retention, making DoTwistBall an ideal tool for stable machining in demanding 3D profiling and high feed applications.

The MJ radius insert geometry is popular among manufacturers profiling mould and die parts. The insert features a large cross section that has been designed to absorb the cutting forces, providing higher reliability and performance over conventional round inserts. The cutting edge integrates a large inclination angle to promote smooth chip evacuation. The addition of the both 05 and 06 styles will further broaden the ability of the series.

The high-feed HJ geometry insert promotes highly efficient machining through 30% greater cutting depth and feed rate over conventional high feed inserts. The maximum depth of cut for the existing 04 insert is 1.3mm while the new 06 insert is suitable for cutting at a depth of 2mm per pass, making the tool perfect for various operations including shouldering, facing, slotting, pocketing and helical interpolating.

Two standard grades are available and these include the AH3135 for steel and stainless steel as well as the AH120 for cast iron machining. The cutter body lineup is available with a shank type, modular type and bore type for all three insert sizes with various choices of tool reaches.