For Maximum Cutting Performance: Tebis Implements Innovative 5-axis Milling Technology

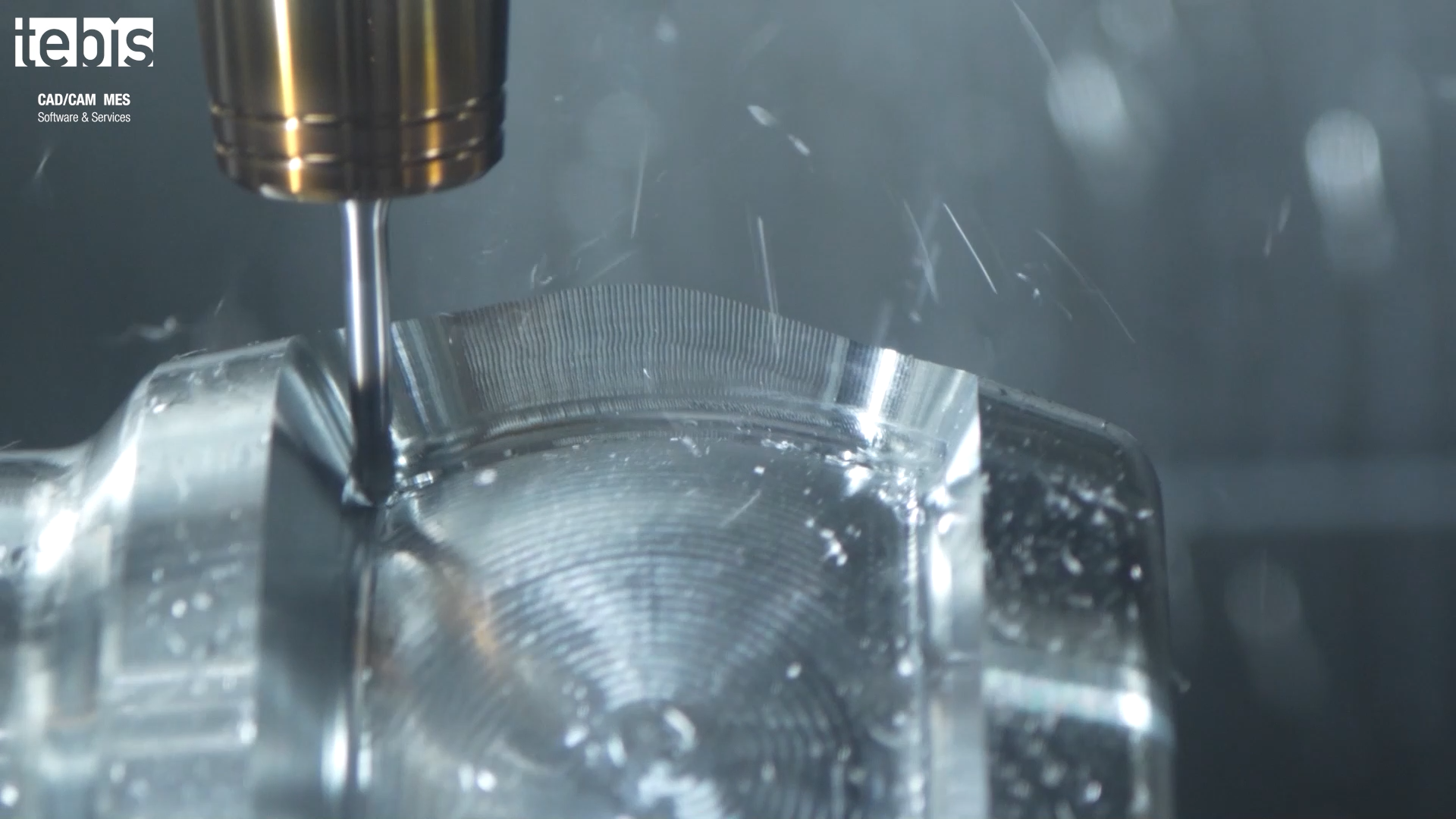

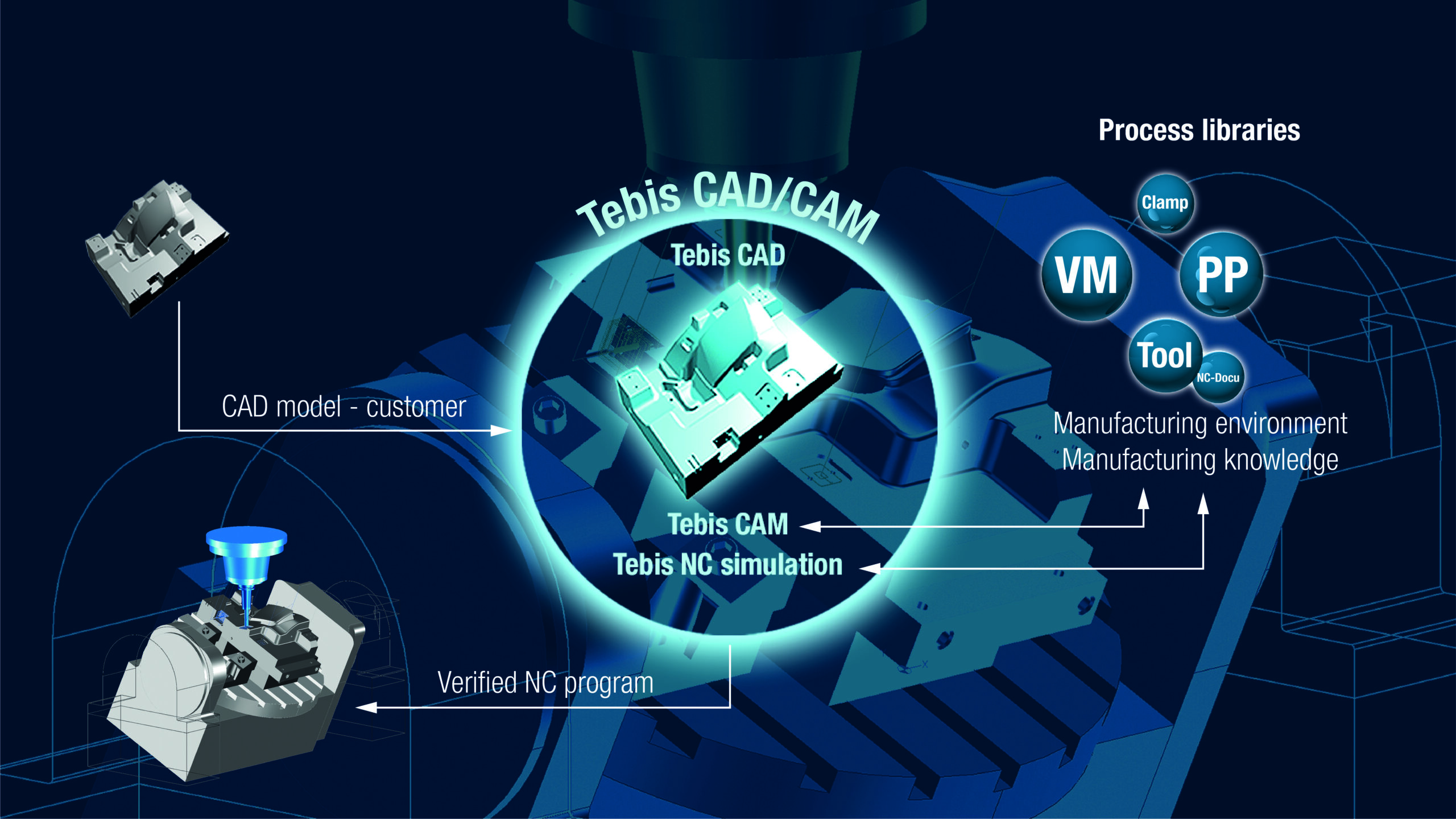

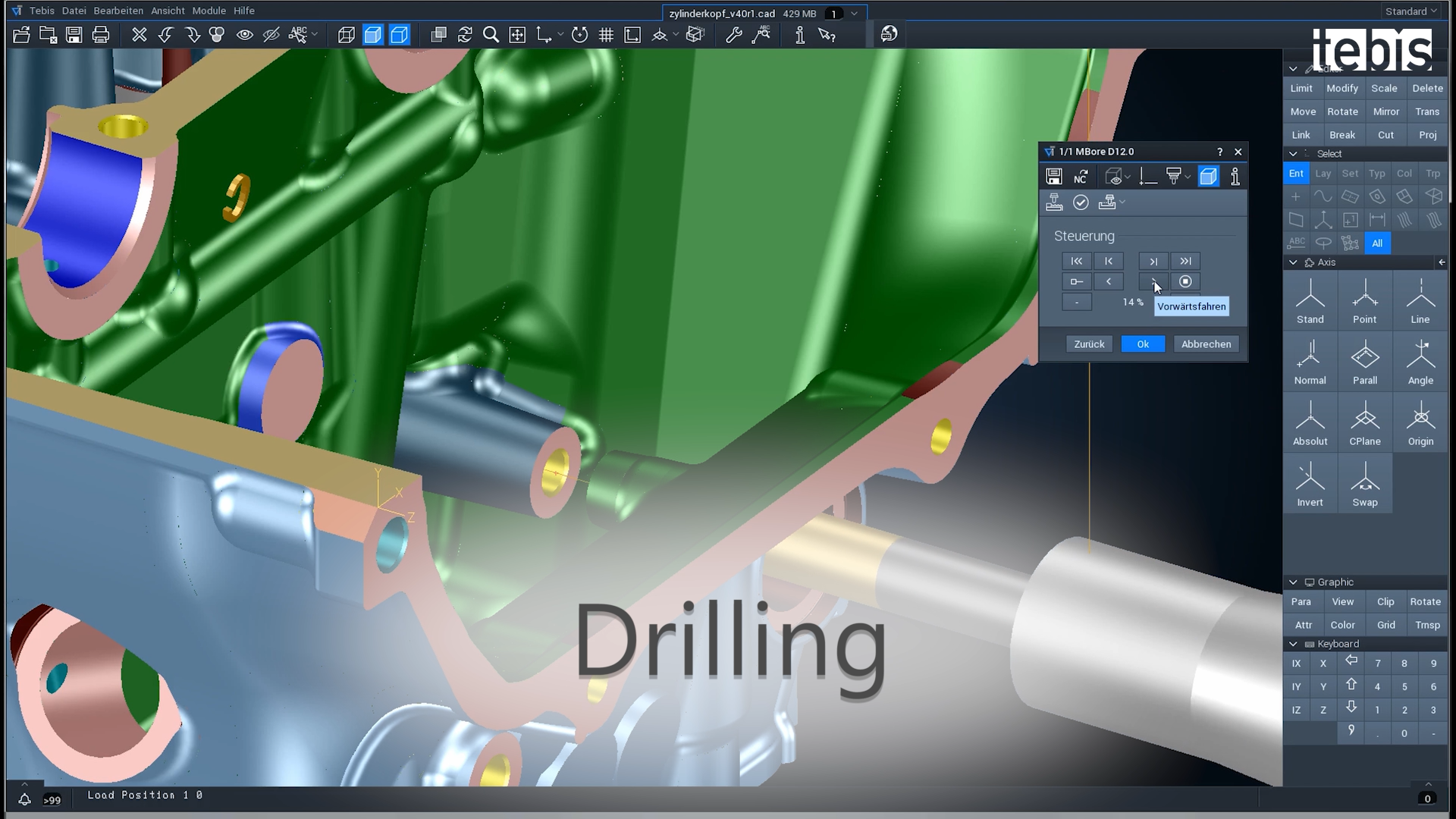

Tebis, a specialist in CAD/CAM and MES process solutions in model, die and mould manufacturing, supports a variety of machine technologies such as milling, turning, drilling, laser cutting and much more in the CAM environment. In the area of milling, the company from Martinsried, Germany, is currently focusing on 5-axis milling and is significantly expanding its spectrum of NC strategies and implementation options.

Bernhard Rindfleisch, Tebis founder and chairman of the board, explains: "Tebis users have been programming 5-axis NC programs for more than 20 years. We’ve continuously developed the technology, but we recognised the need for a change in direction. In the past, creating good 5-axis programs meant a significant amount of design effort and strong expertise in CAD surfaces.

Users have become more specialised

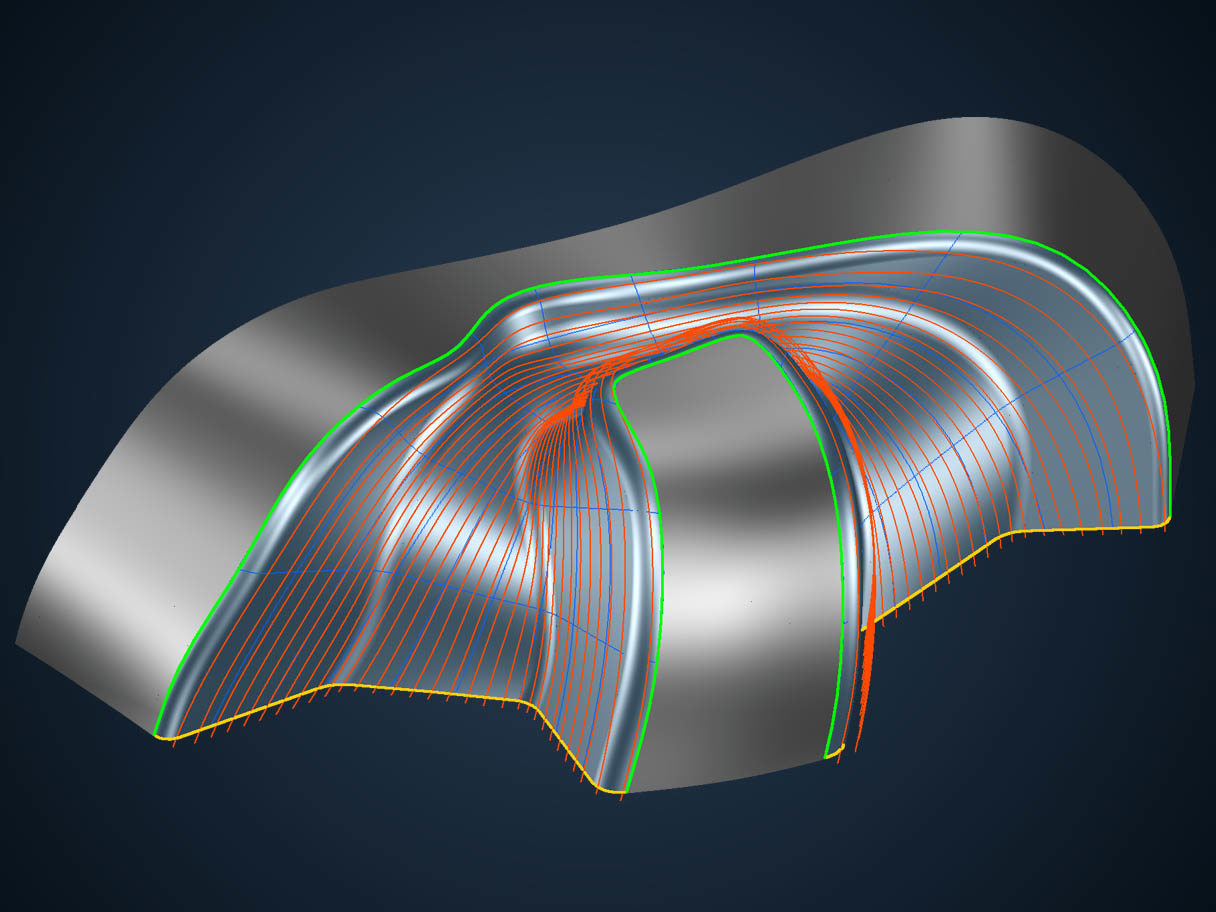

"In many cases, additional guide geometries had to be designed in our software in order to define how the cutters should traverse the part: specifically, their spatial orientation and path distribution," says Rindfleisch. "However, this requires that the NC programmers have the requisite skills, which are becoming increasingly rare. Therefore, we have modified, simplified and extended our 5-axis milling technology over the years."

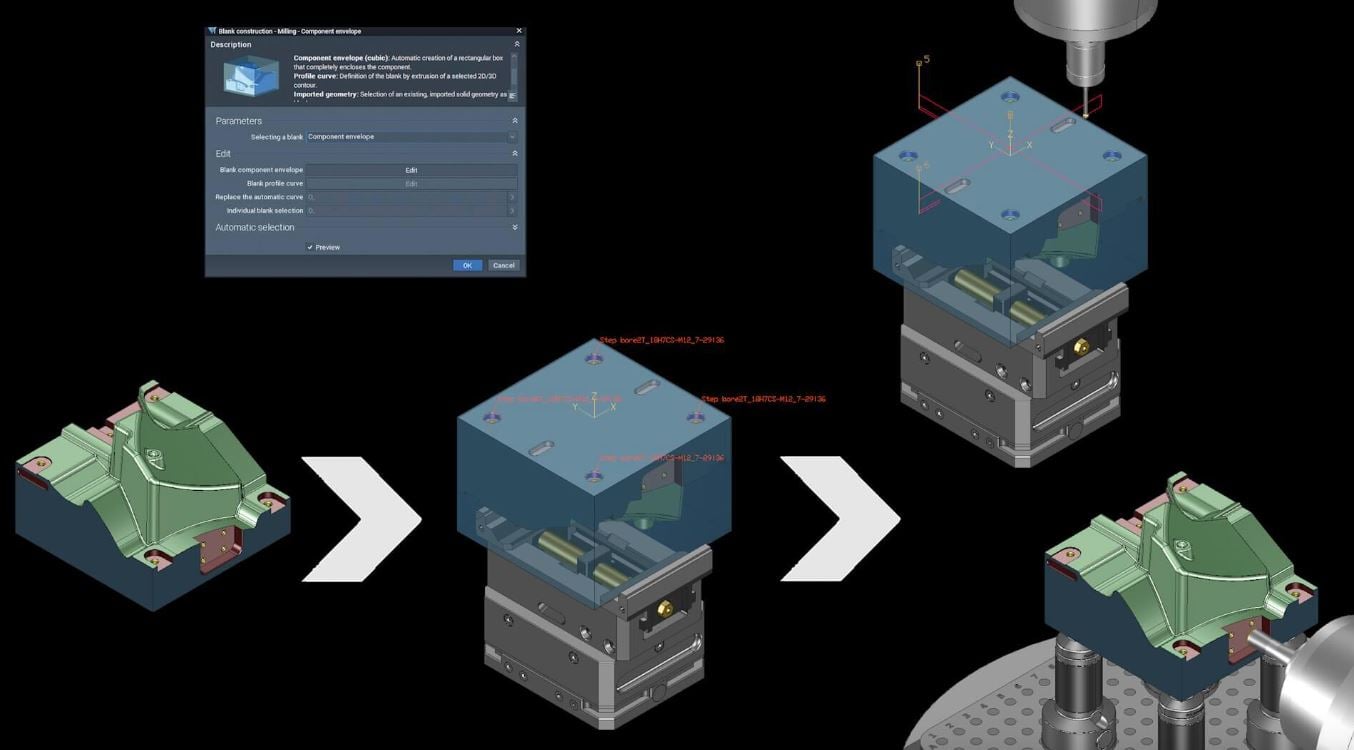

Rindfleisch clarifies: "Now any CAM user with no CAD experience can calculate 5-axis NC programs for roughing, face and side finishing, machining contours and engraving. NC programming is just as easy as for 3-axis machining operations."

Substantial time-savings, thanks to maximised cutting performance

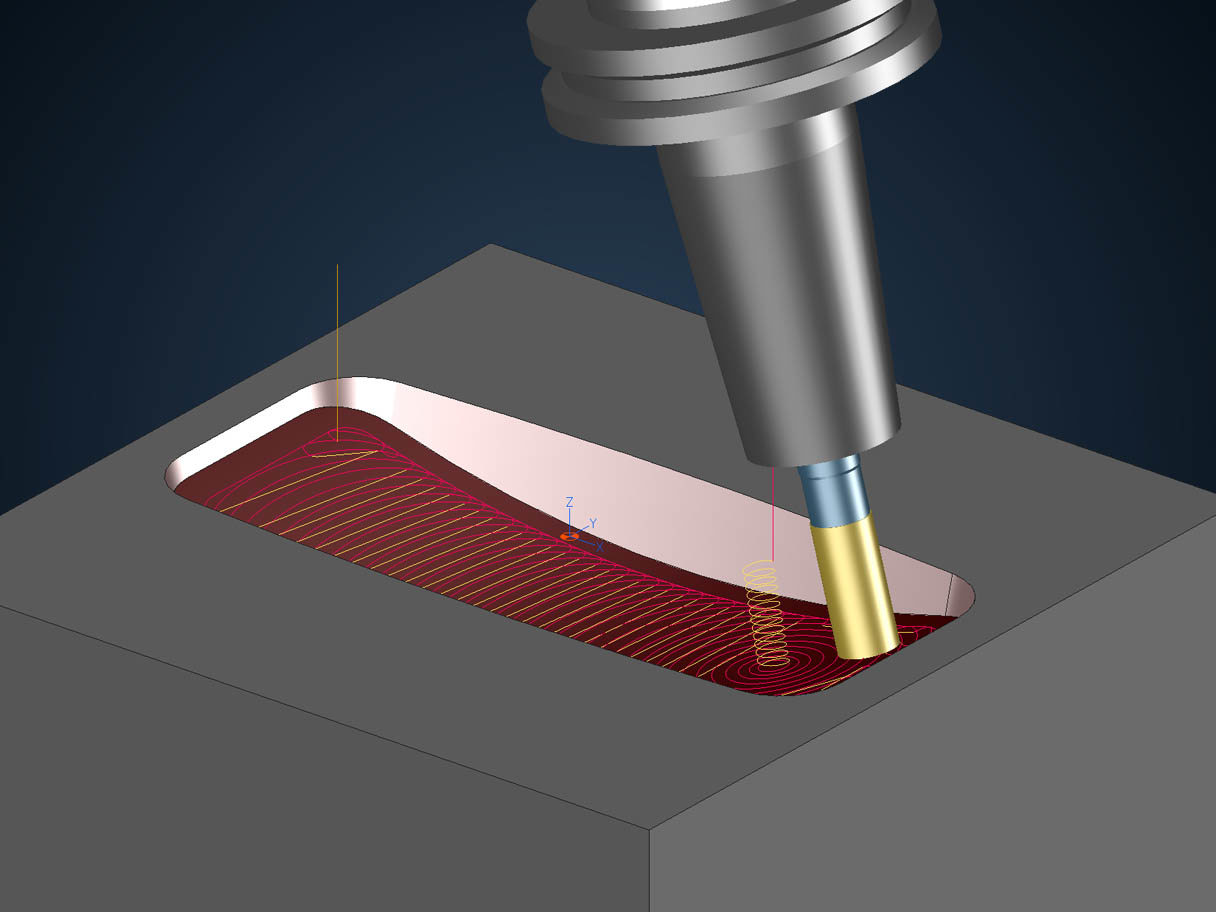

Experience shows that 5-axis NC programs can save a lot of time on the machines, if they are operated with special high-performance cutters like circle-segment cutters. This applies to prismatic 2.5D geometries like pockets as well as 3D free-form geometries.

5-axis machines need 5-axis NC programs

In addition to the X, Y and Z coordinates, 5-axis NC programs have two additional specified axes, typically rotational axes like the A and B axis that are used to define the 3D orientation of the tool. NC programs with specifications for five machine axes are generated in various ways:

• By 3-axis NC programming with constant 3D tool tilt direction. This is also known as multi-sided machining. These are not simultaneous 5-axis programs, because only three axes are traversed simultaneously.

• By 3-axis NC programming with automatic conversion to simultaneous 5-axis programs. The conversion is performed for collision avoidance and to achieve better cutting conditions through a constant change in the tool direction. This is frequently known as 5-axis avoidance milling

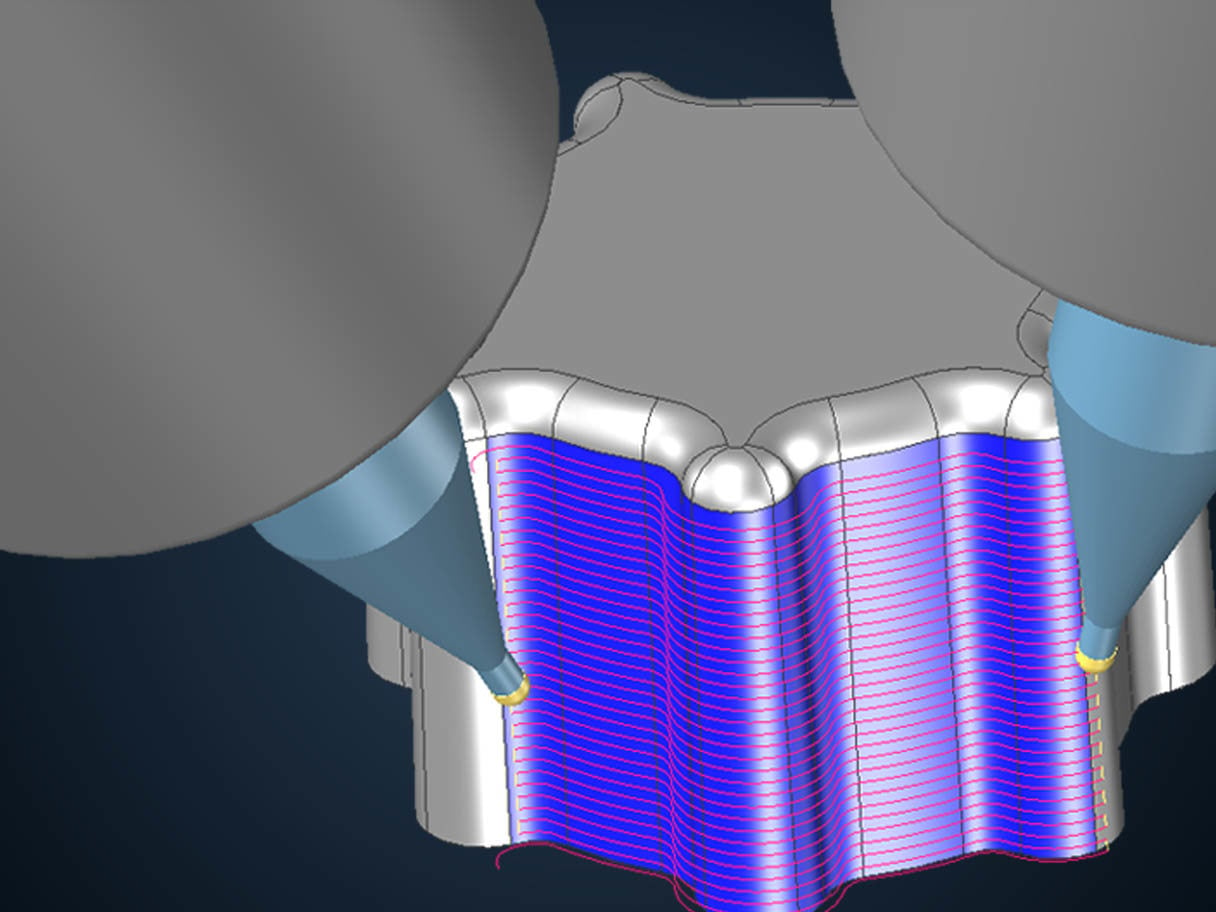

• The third possibility involves using specialised 5-axis simultaneous NC functions. In Tebis, this includes roughing free-form geometries and free-form pockets – also with curved bottoms – milling along contour curves, side and face finishing.

The NC programmer often decides which program will be the most efficient and generates the best surface quality for each application. The availability of milling tools and knowing the correct cutting data like feed rates and speeds are also important. The NC automation (Automill) integrated in Tebis helps to save and optimise programming expertise as well as cutting data in NC templates and make them available on a continuous basis to the NC programmers.

5-axis programming functions as optional add-ons

Tebis software is provided in specialised industry packages. All of the packages are designed for 5-axis NC machine programming and can be upgraded with special add-on modules. Tebis offers add-ons for multi-sided machining, 5-axis collision avoidance, 5-axis roughing, 5-axis finishing, side milling and undercut milling. A large range of cutter types are supported, from ball cutters and lollipop cutters to flat, torus and circle-segment cutters.

Get in touch with the team today to arrange a demonstration! Simply click here and fill out the form. We will be happy to help you.