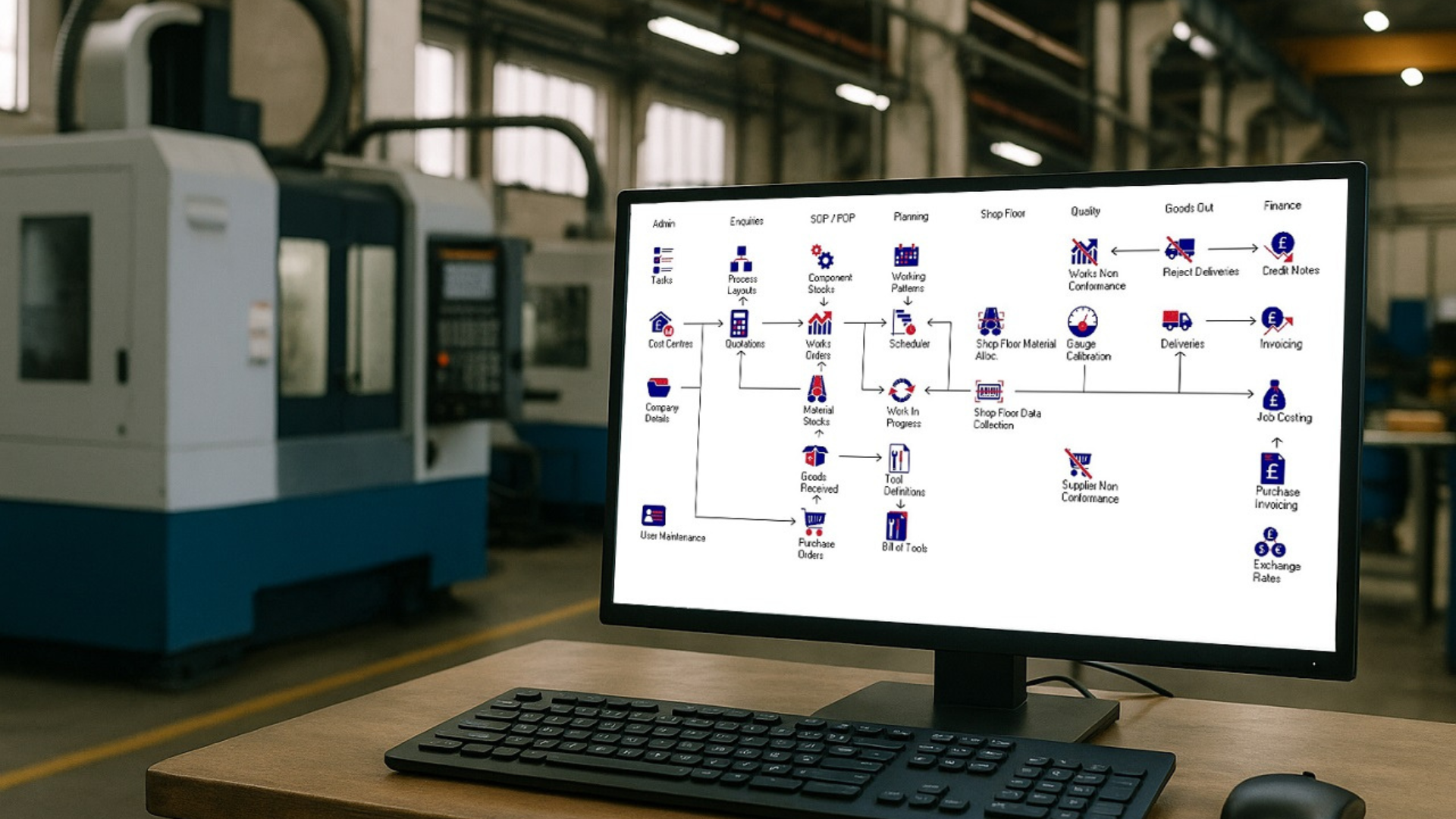

Inventory Management for Precision Engineering: How PSL Datatrack Can Help

Effective inventory control is essential in the world of subcontract precision engineering, where accuracy, traceability and cost-efficiency are critical elements for growth and success. Choosing the right inventory management software can significantly impact your ability to meet tight deadlines, maintain quality standards and improve profitability, year-on-year.

Why Inventory Management Matters in Precision Engineering

Precision engineering businesses often deal with complex assemblies, tight tolerances and high customer expectations. A misplaced or missing material can bring production to a halt, delay delivery schedules or even jeopardise customer relationships. That’s why real-time inventory control is a necessity, not a luxury.

Strong inventory management software provides clear visibility of what stock is available, where it is, how much is in use and what needs to be reordered. For subcontract manufacturers, this translates to fewer errors, better resource planning and maintenance of a steady cash flow.

Key Features of PSL Datatrack’s Inventory Management Capabilities

PSL Datatrack offers dedicated modules tailored to the needs of precision engineering businesses, including:

Material Stocks

- Real-time tracking of raw materials (whether bars, billets, sheets, pieces or coils), part-used bars and certified stock

- Full traceability of material certificates for ISO 9001 compliance

- Management of stock by size, length, grade and supplier

- Storage location tracking to ensure quick and easy retrieval

Click here to find out more about the Material Stocks module

Purchase Orders

- Generate purchase orders based on stock levels and job requirements

- Automatically link materials to works orders for accurate planning

- Maintain supplier records for cost comparison and procurement efficiency

- Ensure materials are ordered just in time to reduce excess stock

Click here to find out more about the Purchase Orders module

Component Stocks

- Complete traceability of every stocked component for quality assurance and ISO compliance

- Track the origin, usage and movement of each item for accurate inventory records

- Maintain optimal stock levels with minimum quantity prompts to avoid production delays

- Improve production efficiency by ensuring components are always available when needed

Click here to find out more about the Component Stocks module

These features ensure your inventory management software works hand-in-hand with production planning, making your business more agile and responsive.

Benefits for Subcontract Precision Engineers

- Improved traceability with integrated certificate and batch tracking

- Reduced stockholding costs thanks to smart purchasing and usage details

- Minimal errors through systemised control of stock movements

- Enhanced efficiency with instant visibility of material availability

Conclusion

If you operate in the precision engineering sector, investing in the right inventory management software is crucial. PSL Datatrack’s Material Stocks, Purchase Orders and Component Stocks modules offer an integrated solution designed specifically for subcontract manufacturers.

PSL Datatrack delivers the tools you need to improve traceability, manage costs and streamline stock control – and so much more. Whether you’re focused on staying audit-ready, managing costs or supporting business growth, the system is built to keep you competitive at every stage.

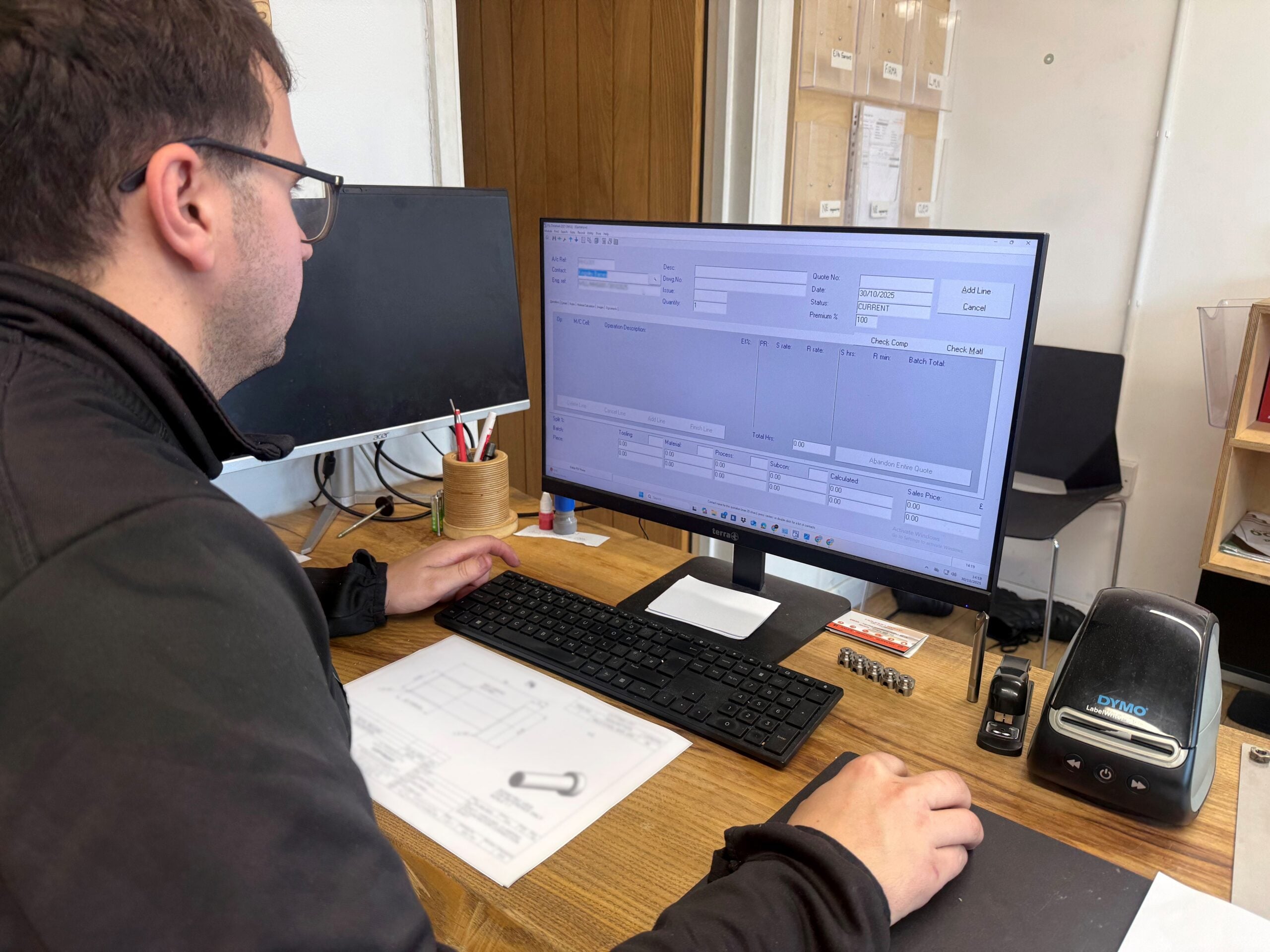

Want to see how it works in action? Explore our vast range of customer success stories and testimonial videos.