Unlocking Workshop Efficiency: Navigating the Path to Automation with SCHUNK

Nowadays, most workshops seek some level of automation, not just due to the shortage of skilled labor, but also to stay competitive and maximize efficiency. However, shop owners often worry about the complexity and uncertain returns of automation projects.

Implementing automation with a lean approach can mitigate financial risk and save time. Start by addressing improvement opportunities with simple solutions to quickly generate ROI. As confidence grows, shops can explore more complex systems, always opting for the simplest approach that suits their needs.

Machine tending automation extends beyond robots; it’s about maximizing machine uptime. Factors like workpiece complexity, lot size, budget, and experience influence the choice of a cost-effective solution. Technologies like flexible workholding and gripping solutions are crucial for automation, especially in low-volume, high-mix applications.

SCHUNK has been at the forefront of automation projects, offering a range of workpiece holding and handling equipment. Here’s an overview of automation solutions that any shop can adopt to enhance production.

Quick Path to Robotic Loading/Unloading: Starting with robotic machine loading/unloading might seem daunting, but there’s a simple and cost-effective way to begin. Component packages enable the implementation of cobots (collaborative robots) with seamless integration. Cobots are budget-friendly, easy to program, and work safely alongside operators without the need for safety fences.

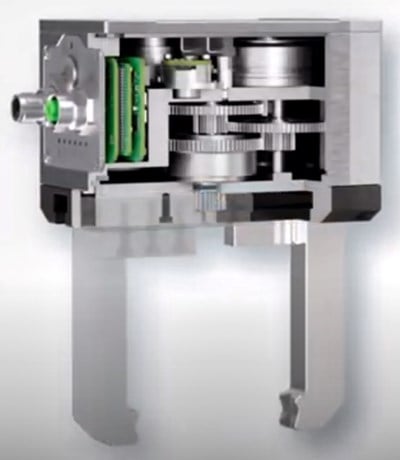

Direct robot loading, accompanied by grippers and automated clamping systems, offers flexibility for larger lot sizes. End-of-arm tooling simplifies setup changes, enhancing flexibility.

Flexible, Pre-packaged Industrial Solutions for Automated Machine Tending: Many machine tool manufacturers offer standard automation options that can be directly added to machines for automated machine tending. Third-party providers like Trinity Automation, Fusion OEM (Robojob), and Gosiger AWR also offer machine-agnostic solutions.

Pallet storage systems are ideal for low lot sizes and high-complexity parts, enabling offline setup and rapid changeover. These solutions offer on-demand machining and unattended operation, meeting the growing demand for contract shops.

Turnkey Solutions: Outsourcing turnkey solutions is an option for complex applications, where providers design and deliver entire systems tailored to specific part and throughput requirements. These solutions can be flexible and adaptable to changing demand volumes and mixes, making them ideal for various applications.

Partnering with professionals who understand automation options and challenges can simplify the process. An ecosystem of automation components facilitates integration, making automation more accessible than ever.

Embarking on automation may seem daunting, but starting with simpler applications can bring immediate benefits. Working with the right partner can streamline the process and ensure automation adds real value to the shop environment.

For more information on automation solutions, visit SCHUNK.com.

Original source from www.mmsonline.com