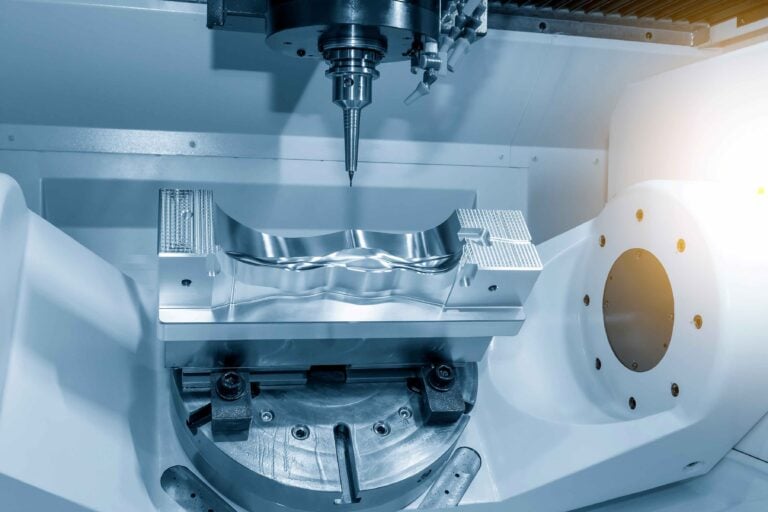

Hexagon’s Manufacturing Intelligence division unveils the HxGN Mould & Die, a comprehensive suite of CAD/CAM, engineering, and automation tools tailored for mould and die manufacturers. Aimed at enhancing efficiency, cutting costs, and ensuring top-quality tools across industries from automotive to aerospace, this suite empowers manufacturers to achieve operational excellence in plastic injection moulds, progressive dies, and similar tooling.

Featuring CAD/CAE capabilities for design engineering, CAM for CNC programming, process simulation, and shop-floor production intelligence, the suite is powered by Nexus, Hexagon’s digital-reality platform, facilitating automation and collaboration. Simulation tools provide actionable insights into the feasibility and cost of mould-making processes, enabling manufacturers to make informed decisions swiftly.

Chuck Mathews, General Manager of Production Software at Hexagon, highlights the suite’s capabilities, emphasizing its integration with Nexus for enhanced automation and collaboration opportunities. Parth Joshi, Chief Product & Technology Officer, underscores the suite’s innovation in addressing customer challenges and accelerating decision-making.

For plastic-injection mould manufacturers, the suite offers comprehensive design and engineering tools, flow simulation, reverse engineering, and CNC machining capabilities. Reverse engineering tools streamline the creation of solid models from scanned data, while plastic flow analysis ensures cost-effective and reliable moulds.

Progressive die manufacturers benefit from a connected workflow with tools for design, simulation, and production. Flexible strip layout capabilities and springback prediction enhance control over the forming process, while advanced machine tool utilisation is facilitated through trusted Hexagon VISI and WORKNC software.

With its array of features and capabilities, the HxGN Mould & Die suite heralds a new era of precision and efficiency in mould and die manufacturing. Explore more at here

Original source Asia Manufacturing News