Tungaloy Expands AH3225 PVD-Coated Grade for Broader Milling Applications!

By Ashutosh Arora

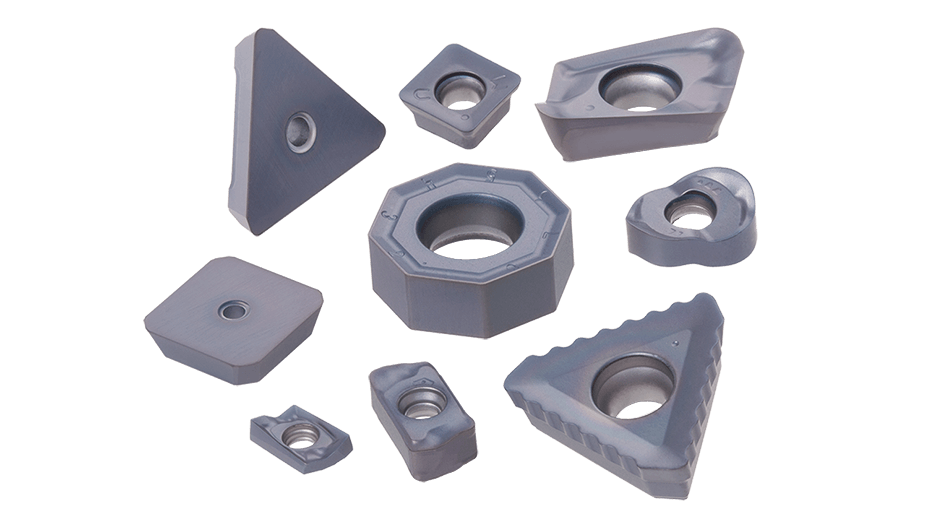

Tungaloy Corporation has announced the expansion of its AH3225 PVD-coated grade across a wider portfolio of milling tools, enhancing its versatility and enabling manufacturers to take advantage of its proven performance in more applications. The AH3225 grade, originally developed for demanding steel machining, is now available for high-feed cutters such as MillQuadFeed, face milling cutters like DoOcto, shoulder milling cutters including TungTriShred, and ISO insert geometries such as SDKN42 and TEEN32.

Engineered with Tungaloy’s proprietary “Triple Nano Coating” technology, AH3225 provides a unique balance of wear resistance, fracture toughness, and oxidation resistance. This combination ensures reliable cutting performance in ISO P steel applications, where maintaining tool life and machining consistency can be challenging under high-speed and high-feed conditions.

The coating technology significantly improves resistance to crater wear and flank wear, two of the most common issues that shorten tool life and compromise machining stability. By mitigating these wear mechanisms, AH3225 extends tool longevity, minimizes dimensional variation, and maintains surface finish quality throughout long production runs. For manufacturers, this translates into fewer tool changes, greater process stability, and more consistent part quality across batches.

The AH3225 grade also allows higher cutting speeds and feed rates without compromising tool integrity. By supporting aggressive machining parameters, it reduces cycle times and overall production costs while helping shops achieve tighter tolerances and stable finishes. These advantages make it an optimal choice for industries with high-volume steel machining requirements, including automotive, heavy equipment, general engineering, and contract manufacturing.

According to Tungaloy, the expansion of AH3225 into more milling tool lines provides customers with a broader set of options for optimizing productivity. Whether using high-feed milling strategies for roughing, face milling for large surface finishing, or shoulder milling for complex geometries, operators can now apply AH3225 with confidence that they will achieve longer tool life, greater efficiency, and reliable quality.

With this expansion, Tungaloy continues to strengthen its position as a global leader in cutting tool innovation. The company remains focused on developing advanced materials and coatings that enable manufacturers to push machining performance further while reducing operational costs.