Schwanog Tooling Lineup Provides Productive Machining of Precision Parts!

By Ashutosh Arora

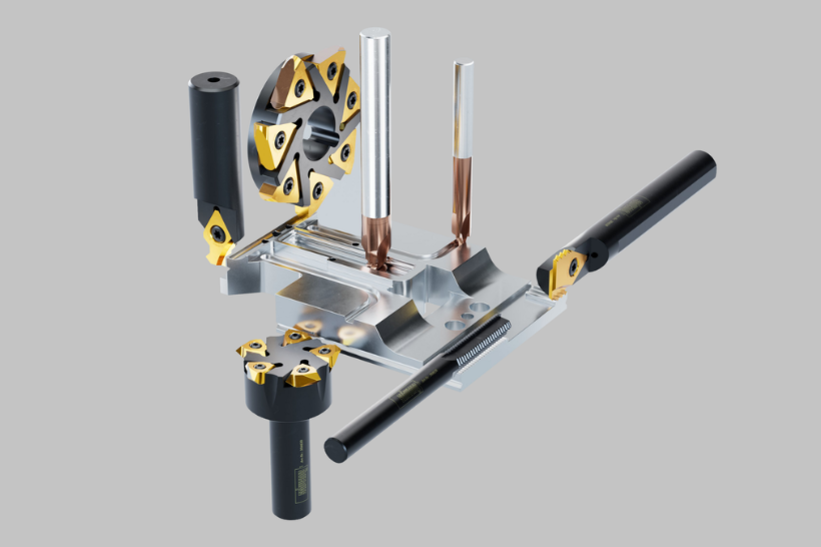

Schwanog continues to expand its reputation as a provider of specialized tooling solutions for high-precision part production. The company’s comprehensive lineup of milling and grooving tools is designed to address a wide range of applications, offering customers efficient, customized solutions that improve both productivity and accuracy. For manufacturers operating in industries that require exact tolerances and high repeatability, Schwanog’s systems present a practical and proven path to achieving consistent results.

The company’s milling cutters play a central role in its tooling range. These tools are particularly well suited for machining threads and internal contours on finishing machines, making them ideal for applications where accuracy and surface quality are critical. Schwanog offers the cutters in a variety of diameter sizes and tooth configurations, giving customers the flexibility to match the tool to their specific requirements. The adaptability of these cutters ensures that they can be integrated into diverse manufacturing environments while maintaining high levels of performance.

For applications that demand the machining of serrations, Schwanog offers its PWP system. This solution is particularly effective in cases requiring high tensile strength and is designed to produce grooves with exceptional precision. The system utilizes a two-edged exchangeable insert that allows grooves to be milled with an accuracy of ±0.01 millimeter. Beyond accuracy, the PWP system also delivers efficiency. Thanks to its quick-change capability and high changeover accuracy, machining can typically resume immediately following a tool change, eliminating the need for readjustment. This reduces downtime, improves throughput, and enhances overall cost-effectiveness for the user.

Another highlight of Schwanog’s lineup is its range of VHM solid carbide milling cutters. These tools are engineered for demanding applications such as machining external gears, outside grooves, and specialized forms on the outer diameter of components. Designed for use in materials with tensile strengths between 1,100 and 1,300 megapascals, the cutters deliver durability and cutting efficiency even under challenging conditions. Depending on the tool’s runout, up to five cutting edges may be available, further extending tool life and improving machining economics. Importantly, the cutters enable finish machining directly on machines equipped with a C-axis, allowing manufacturers to streamline processes by eliminating secondary finishing operations.

By combining high-performance carbide grades, innovative insert designs, and precise tool geometries, Schwanog has developed a tooling portfolio that addresses the needs of modern precision manufacturing. Whether the task involves milling intricate threads, producing highly accurate grooves, or machining complex external features in tough materials, the company provides solutions that balance accuracy, efficiency, and flexibility.

The benefits of Schwanog’s tooling extend beyond the parts themselves. With a focus on quick-change systems and high repeatability, the company enables manufacturers to minimize setup times and maximize spindle utilization. This not only improves productivity but also contributes to more stable and predictable production processes. For industries where precision parts play a critical role—such as automotive, aerospace, and medical—these capabilities translate directly into better quality control and stronger competitiveness in global markets.

Through its ongoing innovations in milling and grooving tools, Schwanog continues to demonstrate its commitment to advancing the productivity of precision machining. The company’s solutions reflect a deep understanding of industry requirements and provide manufacturers with the tools they need to meet the growing demands of high-performance part production.