Rowan University’s Digital Engineering Hub Merges AI and Advanced Manufacturing for Next-Gen Innovation!

By Ashutosh Arora

Rowan University is taking a bold step into the future of intelligent manufacturing with the launch of its Digital Engineering Hub (DEHub) — a cutting-edge laboratory designed to merge artificial intelligence (AI) with advanced manufacturing methods. Housed within the Henry M. Rowan College of Engineering’s Rowan Hall, the new facility aims to bridge the gap between smart digital systems and real-world production environments, accelerating innovation across multiple industries.

Directed by Dr. Antonios Kontsos, the Henry M. Rowan Foundation Endowed Professor of Mechanical Engineering, the DEHub is equipped with state-of-the-art tools that enable both the digitization of physical objects and the creation of new designs — whether engineered by humans or generated by AI. The lab features advanced 3D polymer and metal printers, 3D scanners for object digitization, and mechanical sensing and testing systems, providing a full ecosystem for research, design, and fabrication.

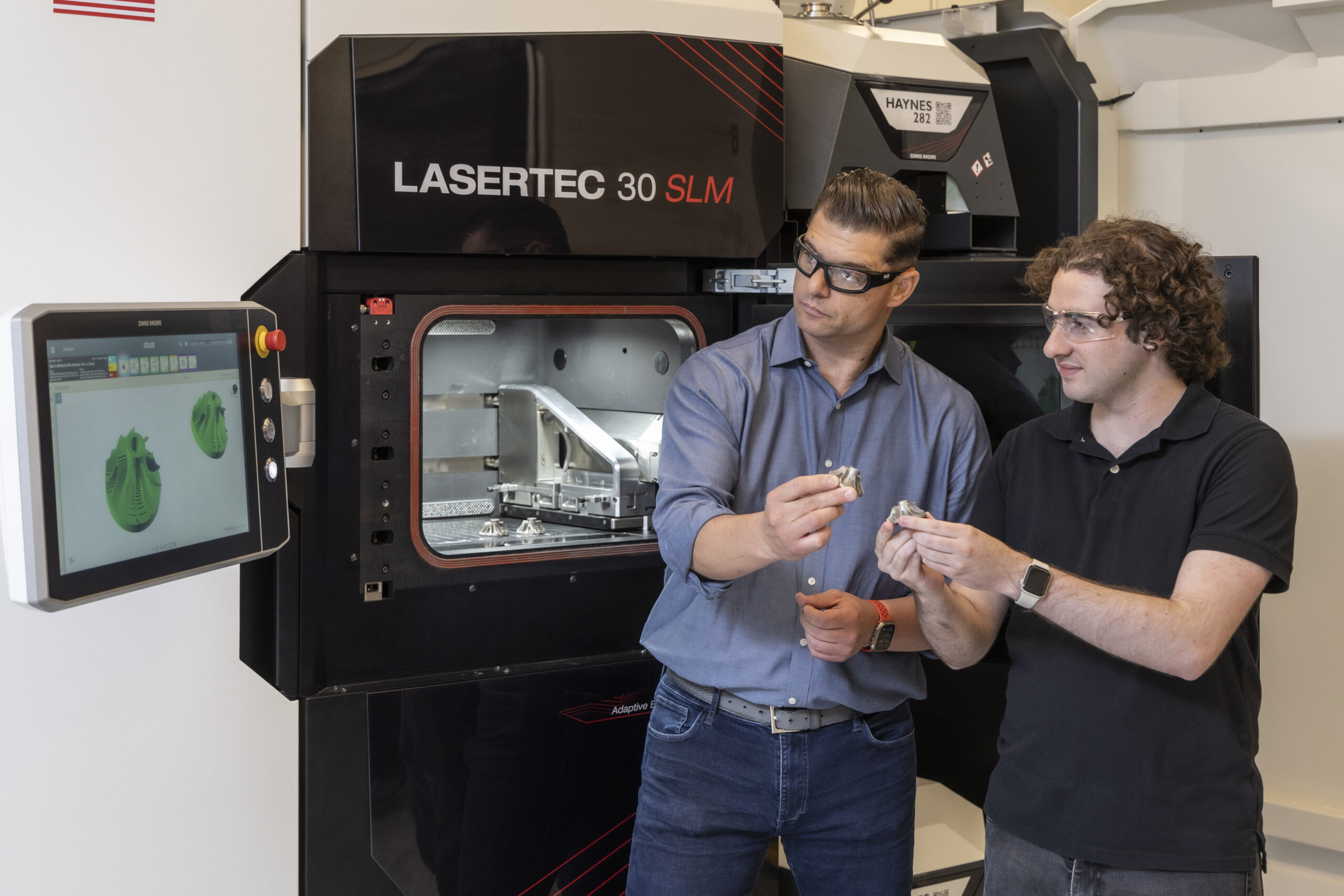

At the heart of DEHub’s technological arsenal lies DMG MORI’s LASERTEC 30 SLM US, a revolutionary 3D metal printer and the first of its kind in the United States. This machine uses a high-powered laser to melt and fuse thin layers of metal powder, producing highly precise, durable components. What sets the LASERTEC 30 SLM apart is its adaptive beam control, real-time process monitoring, and interconnectivity, enabling the detection and correction of manufacturing flaws during the build process — a true leap toward autonomous production.

Powering these advanced systems is Pythia, a supercomputer named after the Oracle of Delphi. Built for high-security, large-scale computation, Pythia processes and analyzes terabytes of data in real time. According to Dr. Kontsos, “We are the first academic research group in the world to connect a supercomputer to this type of machine. The data we’re collecting — such as part temperature and laser activity — requires massive computational power to store and process synchronously.”

This seamless integration of AI, data processing, and additive manufacturing allows researchers and engineers to observe, model, and optimize production processes like never before. The result is a dynamic, data-driven feedback loop that enables smarter manufacturing decisions, predictive quality control, and faster product development cycles.

Initially, DEHub’s research is focused on federally funded projects under the Defense Advanced Research Projects Agency (DARPA), but its long-term vision extends across multiple sectors — including defense, pharmaceuticals, biotechnology, energy, civil infrastructure, and robotics. The lab’s multidisciplinary approach positions it as a key player in shaping the next era of manufacturing innovation.

Interest in the facility has already spread far beyond New Jersey. The DEHub’s launch event drew industry representatives from California, Texas, and even Australia, signaling global attention on Rowan University’s pioneering work in digital manufacturing.

As Dr. Kontsos puts it, “Our goal isn’t just to strengthen the Glassboro economy — it’s to serve as a global resource for advancing smart, AI-driven manufacturing.”

Through DEHub, Rowan University is establishing itself as a national leader in intelligent production systems, combining artificial intelligence, supercomputing, and additive manufacturing to redefine how future products are designed, tested, and built.