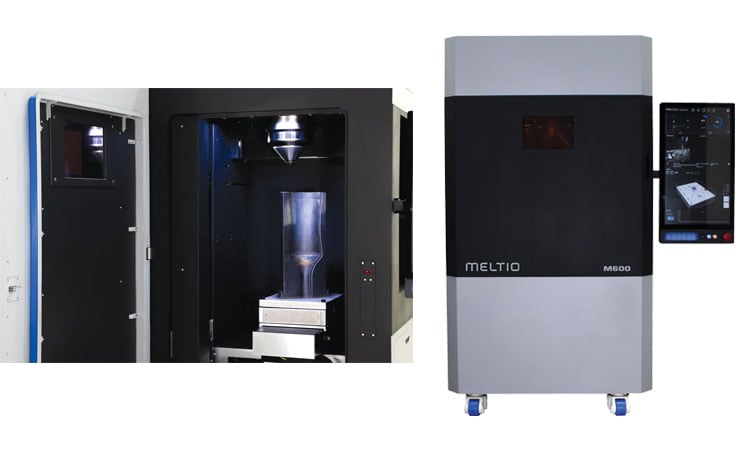

Revolutionizing Industrial Manufacturing: Introducing the Meltio M600 Metal 3D Printer

Unlocking a new era in industrial manufacturing, the Meltio M600 metal 3D printer heralds a transformative leap forward. This cutting-edge technology seamlessly integrates wire deposition, Blue Lasers, and a spacious, inert workspace, setting a new standard in large-scale metal part printing.

Designed to meet the exacting demands of industrial production, the Meltio M600 boasts a robust build volume of 300x400x600mm (X, Y, Z), tailored perfectly for 24/7 production cycles. Its smart sensors and versatile capabilities empower the processing of a wide array of materials, from Titanium to Copper and Aluminium alloys, including stainless steels, tool steels, nickel, invar, and Inconel.

More than just a 3D printer, the Meltio M600 seamlessly integrates into existing machine shops and production environments. It facilitates not only the creation of entire metal parts but also the enhancement of existing components and surface repairs. Equipped with a built-in 3-axis touch probe and support for various workholding solutions, such as zero-point clamping, it offers unparalleled flexibility.

The brainchild of Meltio, a pioneering manufacturer of wire-laser metal deposition systems, the Meltio M600 addresses critical challenges faced by modern manufacturing. By reducing lead times, minimizing inventory costs, and enhancing supply chain resilience, this innovative system revolutionizes production dynamics. Its autonomous operation ensures minimal operator intervention, while its advanced technology enhances productivity and reduces manufacturing costs.

Lukas Hoppe, Research & Development Director at Meltio, envisions the Meltio M600 as the epitome of a 3D printer tailored for machine shop integration. By bridging the gap between additive and traditional manufacturing, it offers a holistic solution to the evolving needs of the manufacturing industry.

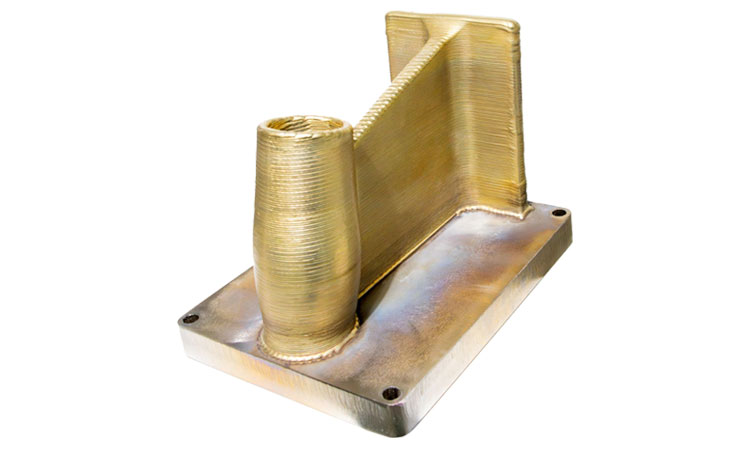

The Meltio M600 introduces a paradigm shift in metal additive manufacturing. Unlike traditional powder-based printers, it utilizes welding wire as feedstock, offering cost-effectiveness and safety advantages. Its Blue Laser deposition head enhances printing speed and energy efficiency, ensuring superior results across a diverse range of materials. Moreover, its fully inert workspace and advanced sensor solutions guarantee exceptional print quality and reliability.

Embraced by sectors ranging from automotive to aerospace, the Meltio M600 transcends boundaries, offering unprecedented value and versatility. Its seamless integration into machine shops and CNC environments streamlines workflows, reduces material waste, and accelerates production timelines.

Cementos La Cruz, a Spanish cement company, exemplifies the transformative impact of the Meltio M600. Leveraging this technology, they’ve revolutionized their manufacturing process, producing sustainable metal parts with unparalleled precision and efficiency.

The success story of Cementos La Cruz underscores the game-changing potential of the Meltio M600 in industrial manufacturing. As the industry embraces additive manufacturing as a cornerstone of future production, the Meltio M600 stands at the forefront, heralding a new era of innovation and efficiency.

Original source from Machine Tools World