OSG USA Expands Tooling Portfolio with Advanced End Mills, Drills, and Inserts!

By Ashutosh Arora

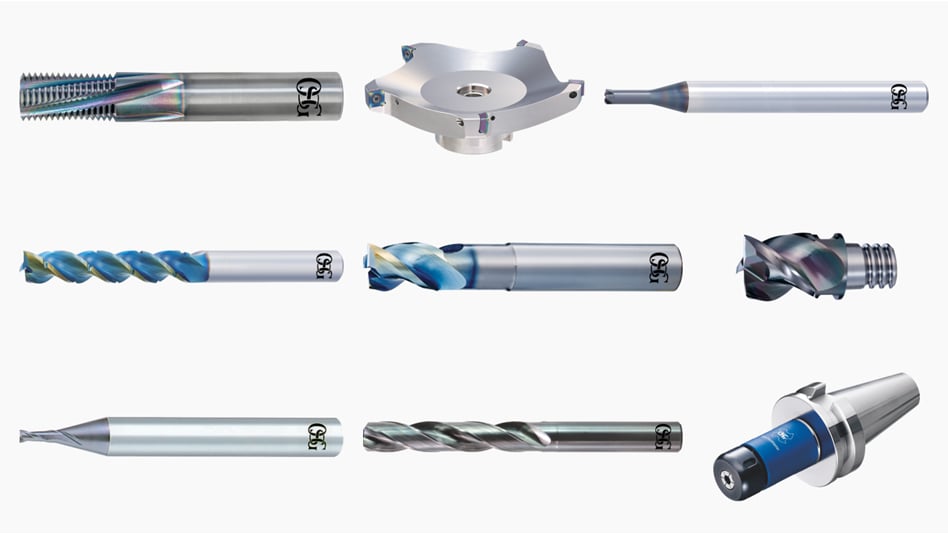

OSG USA Inc. has introduced a significant expansion to its tooling portfolio, unveiling a range of high-performance end mills, drills, and inserts engineered to deliver precision, efficiency, and durability across demanding machining applications. The launch includes new series in the A Brand and Exocarb lines, along with the debut of the Phoenix PSF/PSFL insert for face milling.

The A Brand AE-CPR2-H and AE-CPR4-H End Mill Series are designed specifically for machining hardened steels with exceptional accuracy. The AE-CPR2-H features a 2-flute design for reduced cutting resistance and minimal deflection, ensuring high-quality finishes. Its optimized 3D negative geometry balances sharpness with cutting-edge rigidity, while a flat cutting edge enables precise bottom surface milling. The AE-CPR4-H, on the other hand, offers a 4-flute configuration for high-efficiency milling, enhanced chip evacuation via a new spiral gash, and chatter suppression through unequal index geometry. Both series boast unmatched corner radius accuracy (±0.002 mm) and h4 shank tolerance for secure tool holding.

In addition, OSG has expanded its Exocarb end mill offerings, including the WXL-EBM series made from ultra-fine micro-grain carbide with a proprietary WXL coating for superior wear resistance. These end mills feature high-precision geometry that minimizes rework for mold makers and a thicker core diameter for added rigidity. The company also introduced the Exocarb SEP-EL series, DLC-coated carbide end mills tailored for machining engineering and super engineering plastics. These tools combine sharp cutting edges, low helix angles for reduced cutting forces, and strict dimensional tolerances (0.001″ or better), making them ideal for applications in the semiconductor industry.

The company’s drilling solutions have also been upgraded with additional sizes in the A Brand ADO-40D and 50D Drill Series. These coolant-fed carbide drills, suited for both ferrous and non-ferrous materials, utilize OSG’s EgiAs Nano Coating Technology for enhanced heat and wear resistance. A wavy form cutting edge reduces thrust forces and generates smaller chips for easier processing, while internal coolant holes ensure effective heat dissipation and longer tool life at higher drilling speeds.

Completing the expansion, OSG unveiled the Phoenix PSF and PSFL MCD inserts, designed for 90° indexable shoulder cutters used in face milling. These square inserts feature four cutting edges for extended life and lower cost per edge, compact sizing for lighter depth-of-cut applications, and a sharp 3D chip breaker for reduced cutting forces. Available in both inch and metric styles for end mill and face mill setups, they offer versatile solutions for a range of milling requirements.

With this extensive lineup, OSG USA reinforces its commitment to delivering advanced tooling solutions that meet the evolving needs of industries from mold making to aerospace and semiconductor manufacturing, ensuring machinists can achieve higher productivity, precision, and cost efficiency.