OSG Expands Cutting Tool Portfolio with Advanced End Mills, Drills, and Indexable Inserts!

By Ashutosh Arora

OSG USA Inc. has announced an expansion of its cutting tool portfolio, strengthening its lineup of end mills, drills, and indexable tooling solutions designed to meet the evolving needs of precision manufacturing. The additions enhance performance in milling, drilling, and holemaking applications, particularly for hardened steels and high-demand machining environments. With this rollout, OSG continues its commitment to providing advanced solutions that maximize productivity, extend tool life, and deliver superior surface finishes.

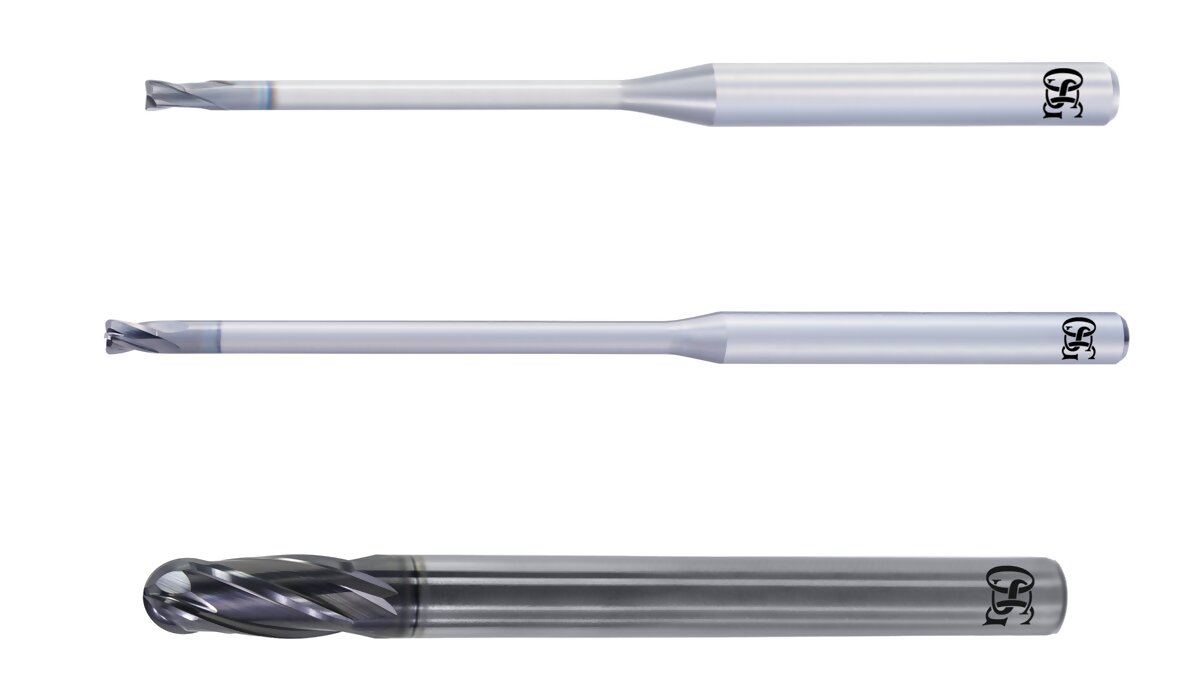

Among the highlights is the A Brand AE-CPR2-H series, a collection of advanced, two-fluted, long-neck corner-radius end mills engineered specifically for hardened steels. These tools feature a two-flute design that reduces cutting resistance, minimizing tool deflection and producing smoother, high-quality surfaces. OSG has incorporated optimized 3D negative geometry to balance sharpness with edge rigidity, while flat cutting edges improve bottom surface milling with minimal wear. The tools also deliver precision through corner radius accuracy within ±0.002 mm and h4 shank tolerance, ensuring secure toolholding in demanding setups.

Building on this, OSG has also expanded its A Brand AE-CPR4-H lineup. This four-fluted, long-neck series enables high-efficiency milling across multiple sizes and configurations. The spiral gash design supports improved chip evacuation, while the unequal index helps suppress chatter for stable, deep-reach milling. With optimized corner radii and high-precision shank tolerances, the AE-CPR4-H series provides consistent performance for intricate part geometries and longer tool life in hardened steels.

For mold makers and precision machining professionals, OSG has extended its Exocarb WXL-EBM end mill series. Manufactured with ultra-fine micro-grain carbide—the hardest, most wear-resistant substrate available—the Exocarb WXL-EBM delivers exceptional durability under extreme cutting conditions. A thicker core diameter enhances strength and rigidity, while OSG’s proprietary WXL coating boosts oxidation resistance and hardness, making it ideal for extended tool life in tough applications. With precise geometry that minimizes rework, the series is positioned as a premium choice for high-end milling.

In holemaking, OSG has expanded its A Brand ADO-40D and 50D drill series. These coolant-fed carbide drills, designed for both ferrous and non-ferrous materials, now include additional sizes. The drills incorporate OSG’s advanced EgiAs nano-coating technology, which increases wear resistance and cutting performance under heat-intensive conditions. A wavy form cutting edge design reduces thrust forces and generates smaller chips, simplifying hole processing while extending tool life. Internal coolant holes further enhance chip evacuation and enable faster, more efficient drilling cycles.

The expansion also extends to OSG’s Phoenix indexable tooling family, with the introduction of the Phoenix PSF and PSFL MCD inserts. These 90-degree indexable shoulder cutters are optimized for face milling and provide high performance at a low cost per edge. Each square insert offers four cutting edges, extending tool life while reducing per-part costs. A compact insert size makes them well suited for lighter depths of cut, while a sharp 3D chip breaker design reduces cutting forces for efficient, reliable material removal.

By broadening its milling, drilling, and indexable solutions, OSG USA Inc. is reinforcing its reputation as a global leader in cutting tool innovation. The company’s continued investment in high-precision geometries, advanced coatings, and optimized designs ensures manufacturers have the tools required to meet today’s toughest machining challenges with confidence and efficiency.