Keyence WM-6000 Handheld CMM Simplifies Dimensional Measurement for Quality Control!

By Ashutosh Arora

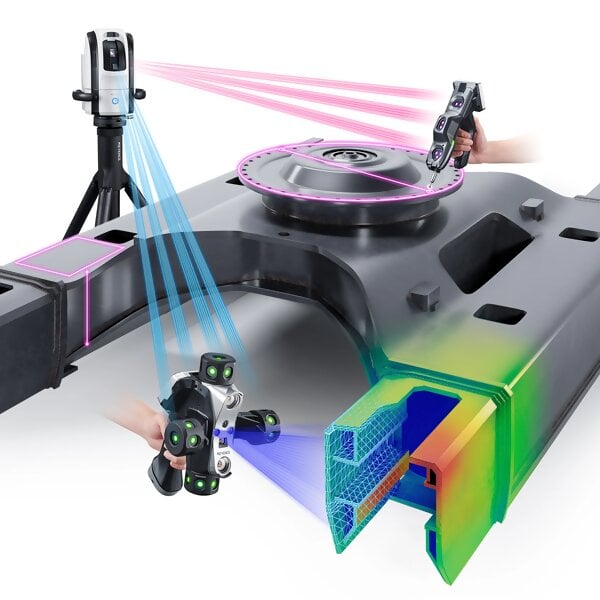

At Eastec 2025, Keyence introduced its versatile WM-6000 Series, a portable, handheld Coordinate Measuring Machine (CMM) and 3D scanner that provides comprehensive measurement capabilities. Designed for use across industries, the WM-6000 is ideal for everything from R&D to quality control. This wide-area CMM allows for easy dimensional measurement and 3D scanning of large parts, offering manufacturers a convenient and efficient tool for maintaining product quality across the production process.

The WM-6000 features an intuitive probe that simplifies the measurement of complex features, such as flatness and straightness. This ease of use ensures that even those with minimal experience in CMM operation can quickly and accurately measure components, enhancing productivity and reducing the likelihood of errors. The system is highly versatile, with applications ranging from automotive parts to medical devices, providing manufacturers with a reliable tool for a broad range of dimensional measurement tasks.

One of the standout features of the WM-6000 is its full-CMM and CAD capabilities, which enable a wide array of advanced measurement functions. This includes 3D/GD&T measurements, contour profile checks, CAD comparison, and even reverse-engineering. These features make it possible to perform comprehensive inspections, ensuring that products meet exact specifications at various stages of production.

The WM-6000’s CAD software can be seamlessly integrated with other industry-standard software tools, such as Polyworks, to streamline workflows and improve the overall efficiency of the quality control process. This integration allows manufacturers to easily transition between design, prototyping, production, and final inspection, ensuring that quality standards are met from start to finish.

With its portable design and robust capabilities, the WM-6000 is an ideal solution for manufacturers looking to enhance their quality control processes. Its ability to scan and measure large parts with precision makes it an essential tool for a wide range of industries, from automotive to medical device manufacturing. By providing manufacturers with the ability to quickly verify product specifications, the WM-6000 helps reduce defects, improve product consistency, and ensure compliance with industry standards.

In summary, the Keyence WM-6000 Series is a powerful, portable tool that offers full CMM and CAD capabilities, enabling efficient and accurate dimensional measurements across a variety of industries. From 3D scanning to reverse-engineering, this handheld system is a game-changer for quality control, offering manufacturers an easy-to-use, reliable solution for ensuring that products meet the highest standards of quality.