When farrier Alfred Högg founded his forge in Lichtensteig in 1905, he could not have imagined that his company would one day span four generations. Today, almost 120 years later, Högg AG Produktionstechnik is located in a state-of-the-art production facility in nearby Wattwil and is a quality company in the metalworking industry, renowned far beyond Eastern Switzerland, with over 50 CNC machines on a 10,000 square meter production area. The machines are all from renowned manufacturers. For cylindrical grinding, Högg has relied on the Swiss grinding specialist Kellenberger for years.

Högg AG Produktionstechnik is one of three pillars of the family-run Högg Group. The company processes around 100 t of steel, 100 t of chrome steel, and 200 t of aluminum every year, and the trend is rising. The products – high-precision parts, custom-made profiles, and assembled assemblies – are used in sectors such as general mechanical engineering, the energy sector, the textile machinery industry, aerospace, micromechanics, sensor and medical technology, and the laser industry. From this powerful foundation, Högg Liftsysteme AG developed in 1990, followed in 2012 by Simplify Engineering AG, a systems provider specializing in the transport of people and goods. The three companies are managed independently but work in a networked manner, leveraging the synergies that arise from their collaboration, such as stairlifts, whose components are designed by simplify engineering AG and manufactured by Högg Produktionstechnik. The entire group employs 160 people, 110 of whom work at Högg Produktionstechnik alone.

Brothers Ivo and Roman Högg are the fourth generation to be responsible for the interests of the entire group and the individual companies. For CEO Ivo Högg, the company’s success factors lie primarily in an open mind, which leads to opportunities being recognized and seized. The mechanical engineer explains: “We are constantly working to define innovations that ensure the company’s success. In an owner-managed family business, long-term strategies can be implemented very well. This creates stability and continuity for customers and employees, and ultimately also for suppliers. Our employees are a key factor. Many have been with us for a very long time, and all are characterized by their high level of professional competence and customer focus.” To ensure this remains the case, Högg has been training its own junior staff for many years.

CEO Ivo Högg, here at the Prix SVC awards ceremony

Stefan Kaufmann has headed production at Högg Produktionstechnik since 2014. He and his 85 highly qualified production employees are proficient in all machining processes, such as turning, drilling, milling, and grinding. In addition to the usual materials such as steel, aluminum, and brass, the company is also equipped to process ceramic parts, for example, for the region’s strong textile industry, and difficult materials such as INVAR, an iron-nickel alloy, which requires special tools for machining.The range extends from smaller workpieces to 6 m long milled special profiles. Batch sizes typically range from 50 to 2000, but single-item production and large series are also not uncommon.The production hall therefore contains a very wide variety of lathes, milling machines and grinding machines.

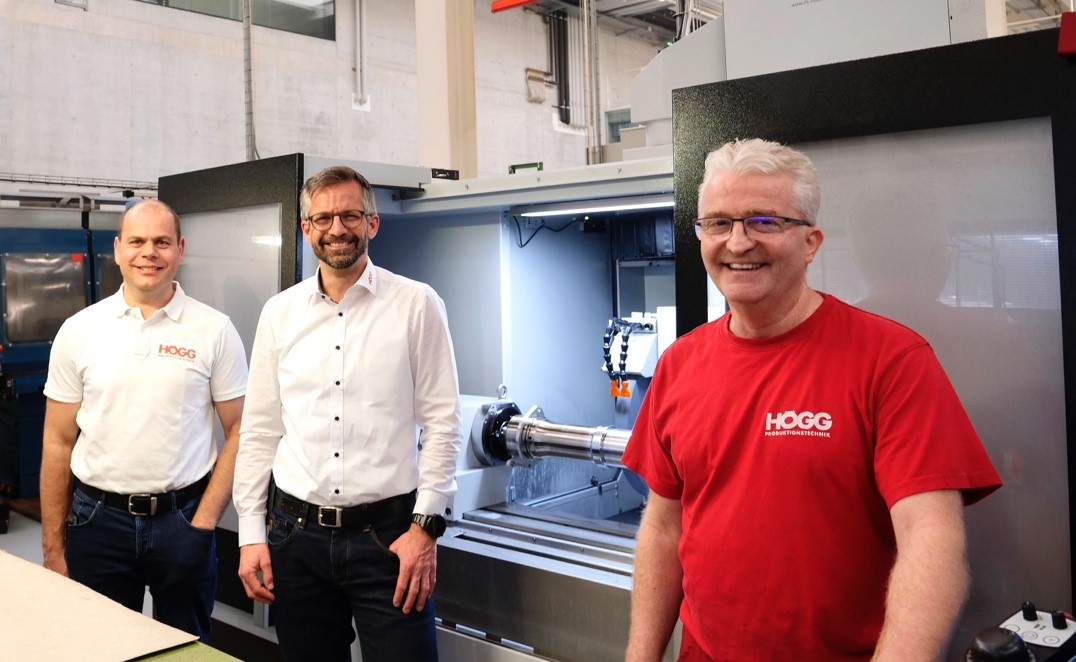

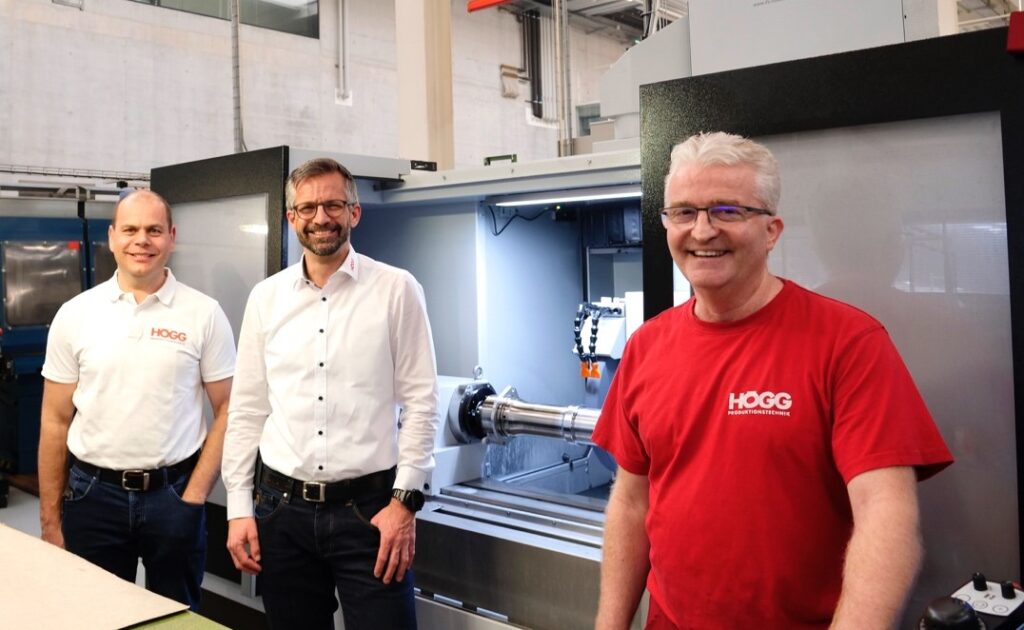

Production Manager Stefan Kaufmann, CEO Ivo Högg, and programmer/fitter Andreas Hausmann have a good laugh. The KELLENBERGER K100 delivers high-precision workpieces and is easy to program.

Grinding technology from Eastern Switzerland

A total of seven grinding machines are located in the grinding area, including two Kellenberger universal cylindrical grinding machines, one of originally two KEL-Varia and, as the most recent addition, aKELLENBERGERK100, which was purchased in 2021. The KEL-Varia universal cylindrical grinding machine – the predecessor of today’s premium Kellenberger K1000 series – stands for the highest machining and surface quality. Its high static and dynamic rigidity and stability form the basis for high precision and high productivity. The performance spectrum of this machine is geared towards the quality requirements of precision manufacturing of prototypes as well as small and medium series.

When purchasing the new cylindrical grinding machineOnly Kellenberger was contacted. Stefan Kaufmann explains the reasons for this: “We attach great importance to considering suppliers from the region whenever possible. The advantage of geographical proximity for us is, of course, that service is available quickly when needed. However, we already do a lot with KEL-Remote, Kellenberger’s online service module. We’re very satisfied with it.”

TheKELLENBERGERK100 is a modular platform solutionwith which different machine concepts can be realized with strong customer orientation.The machine is available with center distances of 1000/600 mm and a center height of 200 mm and is designed for workpiece weights up to 150 kg. The high drive power of the grinding wheel ensures increased productivity, while the newly developed Z-guide ensures high profile accuracy. The C-axis with direct drive provides greater precision in non-circular grinding. This is very important for workpieces such as cam disks, which are manufactured at Högg.

Typical workpiece: Cylinder during grinding on the KELLENBERGER K100. Material: hard-chrome-plated steel, batch sizes typically 1 to 100

The technical highlights of the machine include an innovative compact grinding head (10 grinding head variants, 11.5 kW drive power, 500 mm wheel, up to 63 m/s, HF spindles for internal grinding including diagonal and tandem arrangement), a collision-free universal head with three tool and one measuring position as well as a new measuring probe arrangement without a swivel mechanism for increased measuring accuracy.The reinforced casing allows for the largest grinding wheel diameters for internal grinding (up to 125 mm).

Polymechanic Andreas Hausmann has been working for the company for over 40 years, starting as an apprentice in 1981 and operating and programming Kellenberger machines, among others. He says: “AtKELLENBERGERWe were impressed not only by the K100’s machining quality with an accuracy of 2/100ths, the linear guides, and the good thermal conductivity, but also by the improved accessibility to the well-structured work area and the wider spacing between the spindles. The grinding head, equipped with two internal grinding spindles, is also better arranged.

The KELLENBERGER K100 is equipped with the new Fanuc 31i CNC control with 19″ touch screen. AndreasHausmann appreciates the ease of programming, which is possible directly on the machine with the new BLUE Solution software developed by Kellenberger: “Due to the part specifications, we usually program externally using Kellenberger’s BLACK CAM Solution software, which was developed specifically for non-circular grinding. The control also features a scrap minimization function, which identifies influencing or disruptive factors during a test run.”

TheThe KELLENBERGER K100 is ideally suited for a wide variety of automation solutions. However, even though approximately 30% of all machines at Högg are already automated, they don’t see any need for the KELLENBERGER K100. “That may change, but at the moment, the workpieces don’t allow for it,” says Stefan Kaufmann.

The KELLENBERGER K100 at Högg is configured with a center distance of 1000 mm and a center height of 200 mm and is equipped with a standard tailstock. A synchronized tailstock is available as an option. The machine also impresses with its easy access to the spacious work area.

The consistent attention Högg pays to the highest quality is demonstrated by theSeparation of production areas into steel processing and aluminum processing. Stefan Kaufmann explains: “Aluminum parts are sensitive. However, the surfaces of the machined workpieces, such as cylinder tubes or pistons, must be flawless. Therefore, we pay extreme attention to cleanliness and prevent any flying chips. In particular,Aluminum shavings are critical and should be left in place.“Högg also has a clean room available for the assembly of components for sensitive industries such as the vacuum, semiconductor and solar industries.

Sustainability plays a very important role in the company. From the photovoltaic system on the roof to the groundwater for theHeating orFrom cooling the production hall to the circular economy of materials, everything at Högg is exemplary.100% of electrical energy now comes from renewable sources. The goal is to achieve completely climate-neutral production.

It’s therefore no surprise that the company was not only nominated for the Prix SVC Eastern Switzerland 2022, but also placed among the top 6 and was awarded a diploma. The prize is awarded every two years by the SME network Swiss Venture Club and recognizes exemplary Swiss companies. The key factors for the nomination were the company’s innovative spirit and regional roots. And, of course, its performance. All three aspects are beyond doubt at the Högg Group.