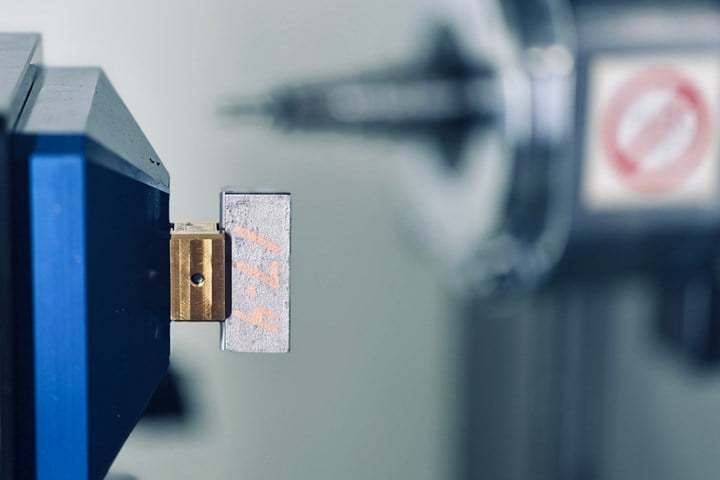

Decoding Stainless Steel Machining: Tips and Tricks for Tool Wear Management

In the realm of machining, stainless steel stands out as one of the most intricate materials to comprehend. Unlike nonferrous materials that are generally easy to work with or iron and carbon steels that offer predictability, stainless steel presents a diverse array of alloys, each with its unique set of machining characteristics. From being soft to super hard, free machining to gummy, and affordable to pricey, stainless steel encompasses a broad spectrum of properties that demand careful consideration.

To navigate the complexities of machining stainless steel effectively, it’s crucial to delve deeper into its classification, special characteristics, forming type, and hardness. Understanding these facets allows for a more nuanced approach to selecting the right tools and optimizing cutting parameters.

Once equipped with the necessary insights, attention should shift to addressing process-specific challenges. From coolant selection and delivery methods to tooling considerations, every aspect plays a pivotal role in combating tool wear and maximizing efficiency.

Furthermore, adopting a proactive approach by investing in spare tooling, allowing ample time for job execution, and prioritizing employee training can significantly streamline the transition to mastering stainless steel machining. By embracing these strategies, shops can enhance their proficiency in working with this challenging yet rewarding material.

Original source mmsonline.com