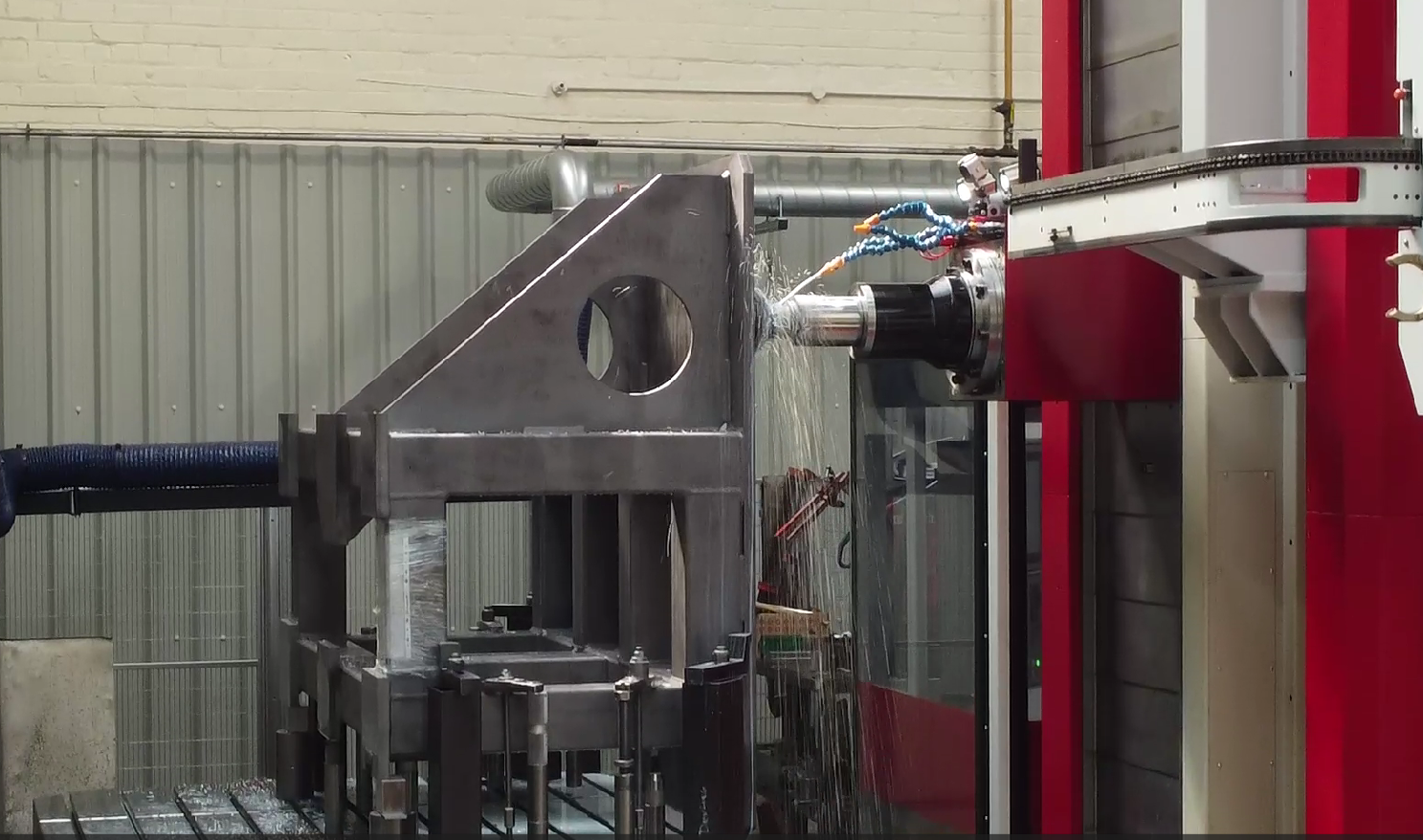

We are pleased to announce the arrival of the Gruppo Parpas Roller. The machine will be installed in an engineering company which already has a most impressive and sophisticated machining portfolio. This additional capacity is required to meet ever an increasing order book which has given them the confidence in investing in yet another top quality 5-axis machine from Parpas.

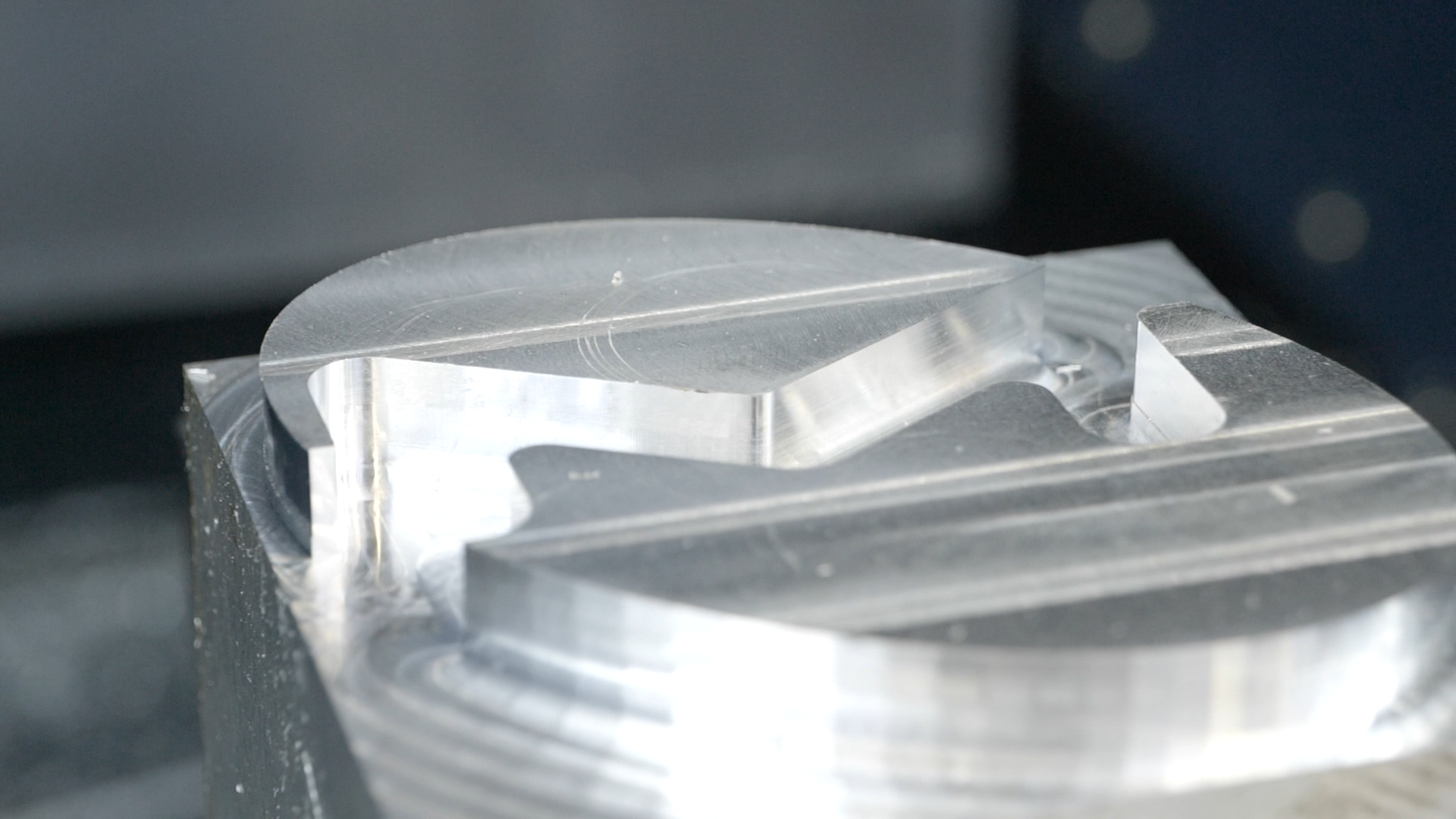

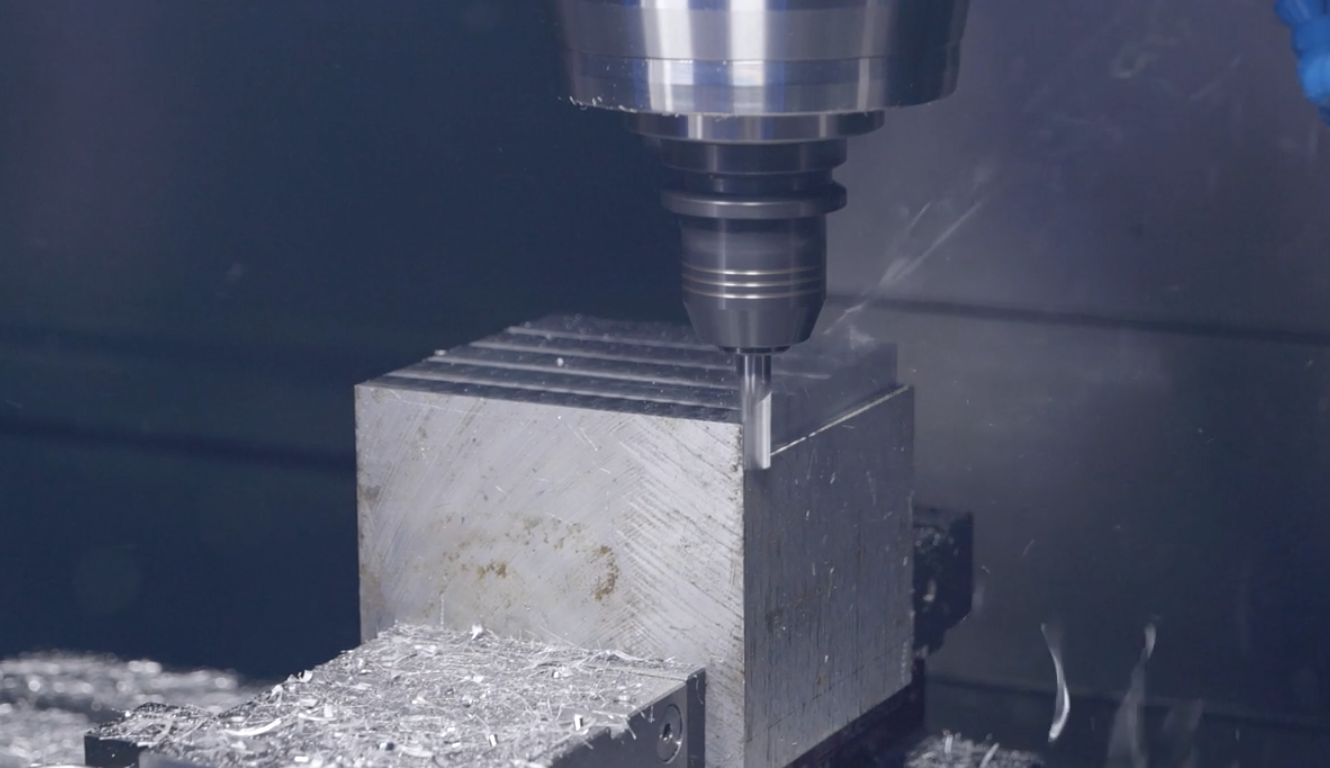

The Roller is one of many impressive machines available from Gruppo Parpas and is perfect for U.K. manufacturers in aerospace, power generation, automotive and die/mould sectors. The Roller is a 5-axis high-speed portal-type machining centre that uses linear motor drives in all axes, providing rapid movement at 60M/min with no vibration or wear due to the elimination of a mechanical drive. To control thermal growth of the spindle carrier and maintain absolute accuracy at the tool point, the linear motor assembly is cooled by four separate chilling circuits.

Similarly, the HSK spindle, likewise chilled and thermally controlled, is driven by a powerful torque motor with a speed of 18,000rpm and 37kW of power. The machine is fitted with a full rotary table, 42 tools, tool measurement, spindle probe and high-pressure coolant.

The Heidenhain 640 control includes Dynamic Collision Monitoring which prevents accidental collisions between the components of the machine tool. The Kinematic function independently measures the rotary axes using a probing cycle and the CNC control automatically compensates the machine static accuracy and axes orientation, storing the geometry of the machine in a kinematics table.