Dugard has announced the arrival of three new ZOPO V8P machining centres at its showroom, all set to embark on their journey to various production facilities. The Zopo V-Series is gaining popularity as one of the most sought-after vertical machining centres, renowned for its efficiency in moving swiftly into active production environments.

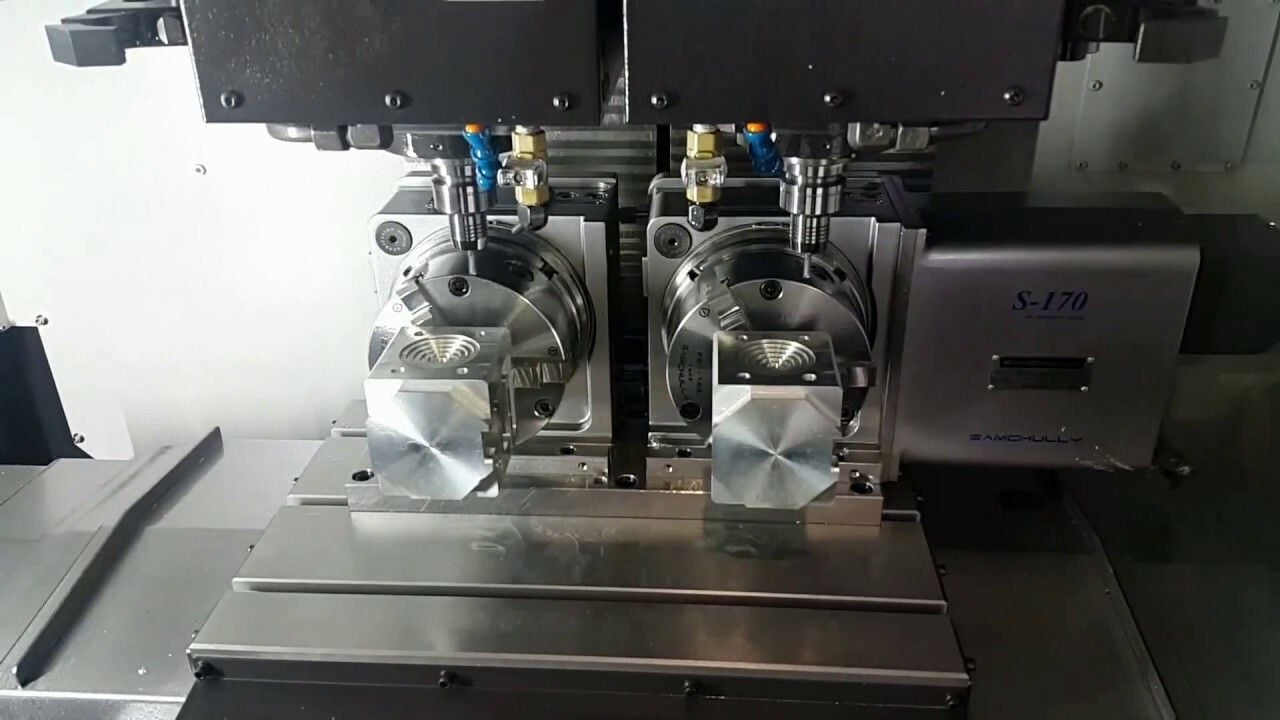

These high-performance machines boast a significant table size of 500 × 1000 mm and travel dimensions of 850 / 500 / 550 mm, with a load capacity of 500 kg. This setup is particularly beneficial for handling heavy and bulky workpieces. The V8P models are equipped with a high-speed direct-drive spindle capable of reaching 12,000 rpm, with an optional upgrade to 15,000 rpm.

The machining centres feature a BBT40 spindle taper and a 24-station automatic tool changer, with an option to expand to 30 stations. Built with high-rigidity hybrid roller-linear-guideways and solid cast iron construction, these machines have been designed for optimal stability and speed through finite-element analysis.

The ZOPO V8P is ideal for producing parts in sectors such as automotive, aerospace, medical, and general subcontract work. Its combination of premium performance and cost-effectiveness makes it a smart investment for both high-mix job shops and volume-driven production lines.

For those interested in a demonstration or securing one of these technologically advanced machines, Dugard encourages potential buyers to contact their sales team.

Dugard continues to support the manufacturing industry with cutting-edge solutions designed to enhance productivity and efficiency in production environments.