Inside CMZ’s New Automated Plant for High-Accuracy Cylindrical Parts

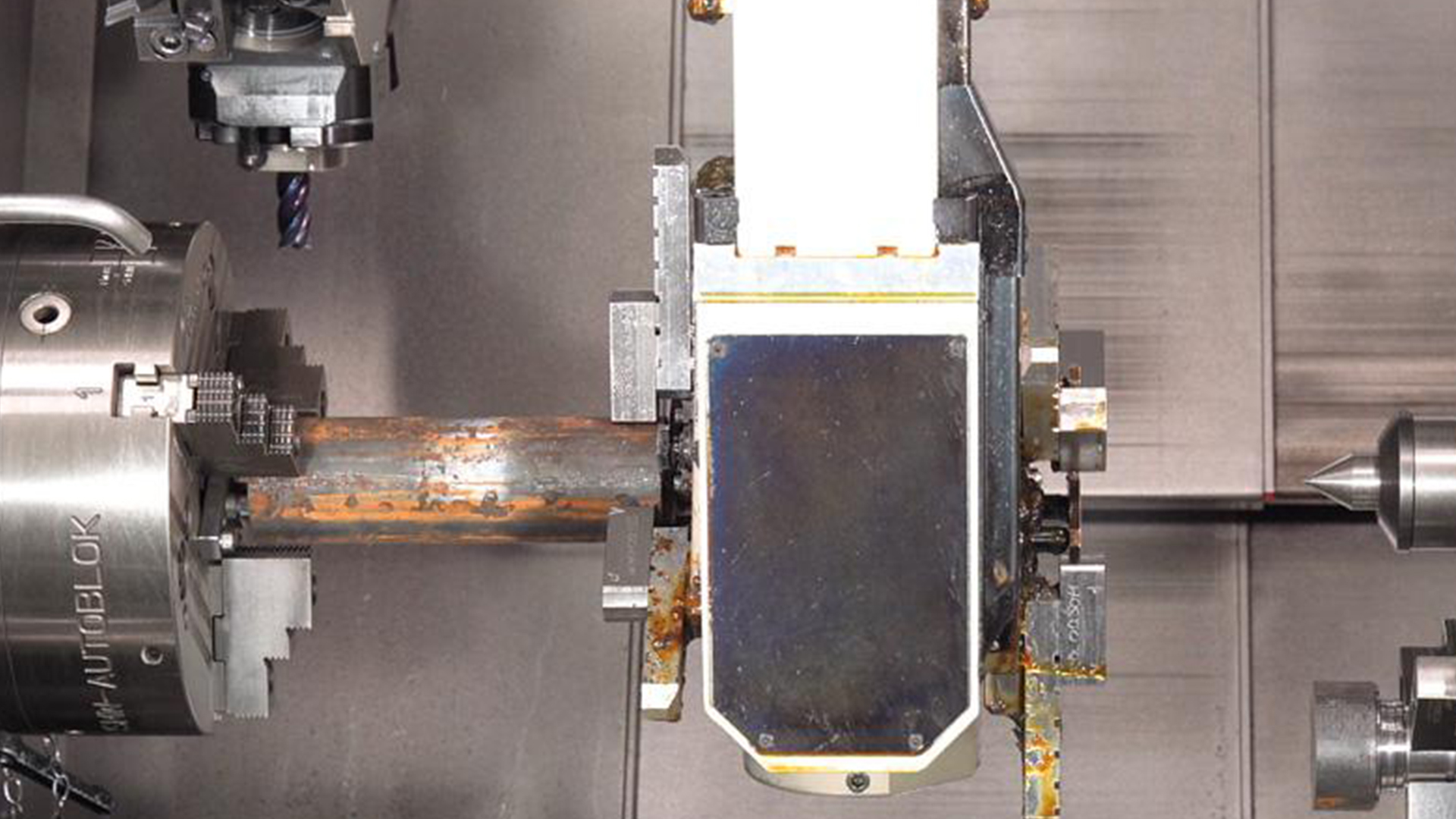

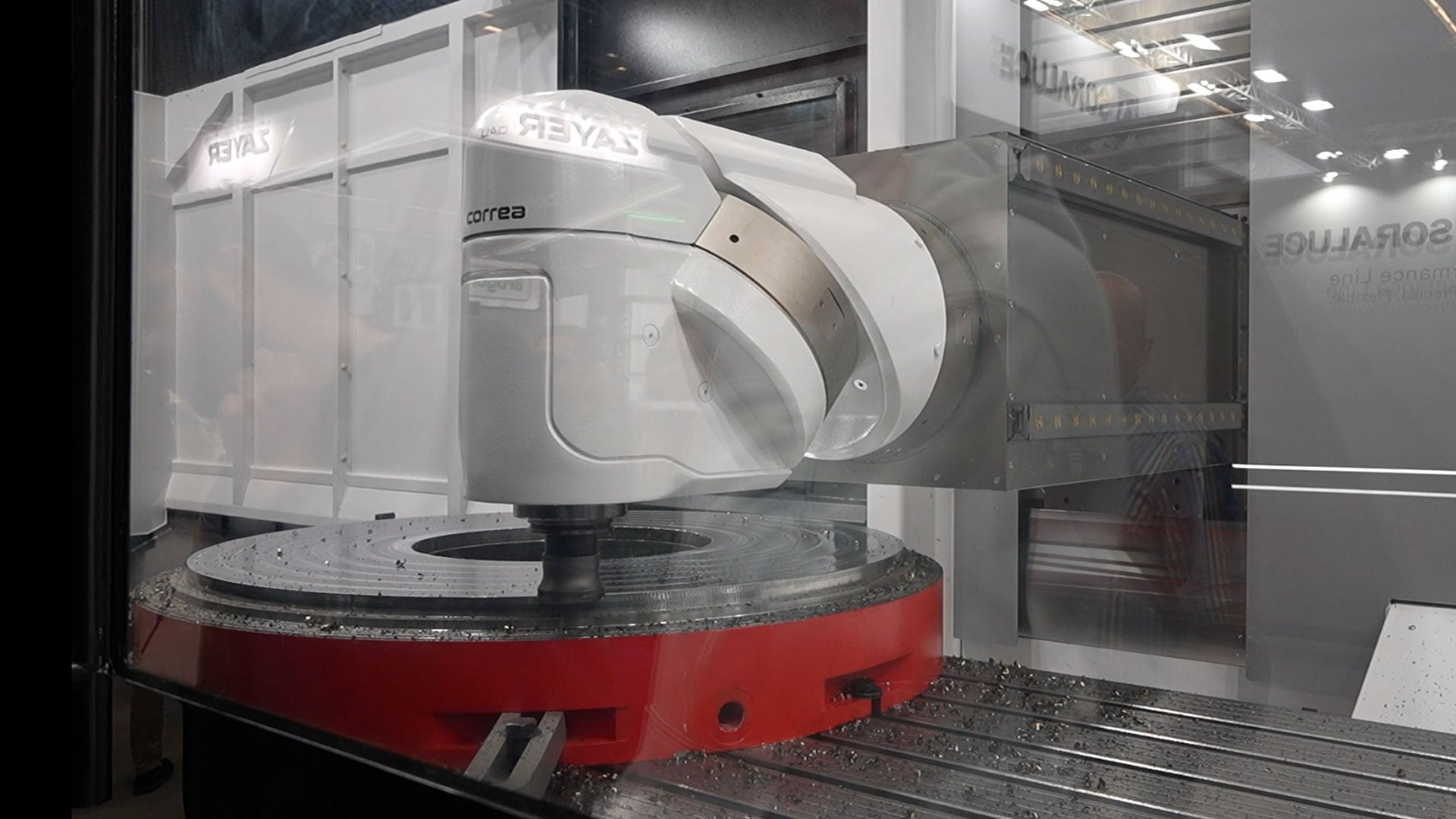

Precitor, CMZ‘s latest plant dedicated to machining high-accuracy cylindrical parts, boasts over 2,000m² of temperature-controlled workspace (±1°C). Here, spindle shafts for driven tool holders are produced using a multi-turret CNC lathe with a tailstock. Thanks to the Gantry Robot Loader, the process is fully automated, significantly reducing cycle time.

The spindle shaft manufacturing process involves several key stages:

- Loading: The gantry loader retrieves raw material from the workstocker.

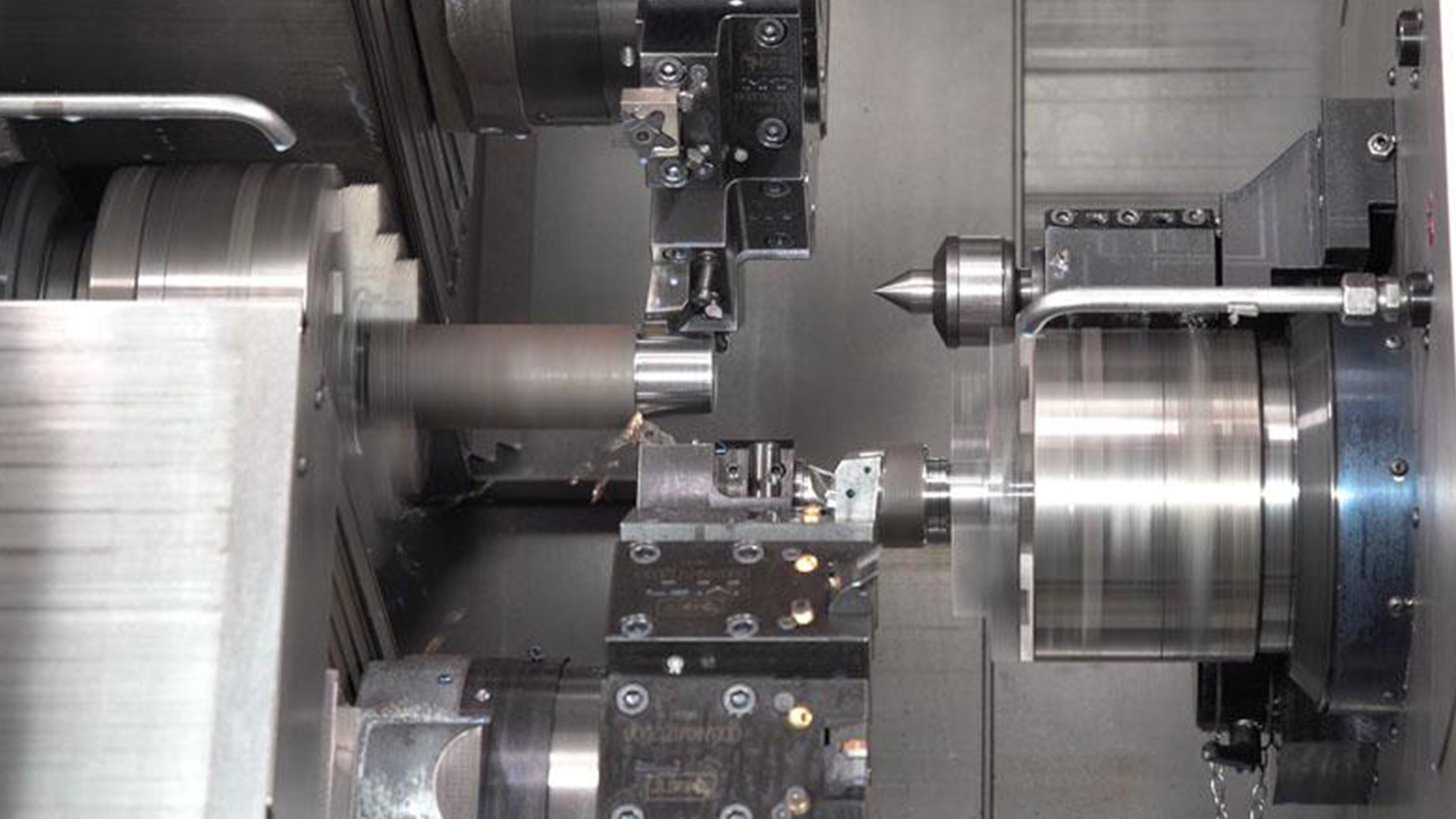

- Turning and Drilling: Due to the part’s length, it is turned using balanced cutting and simultaneously drilled on the sub-spindle.

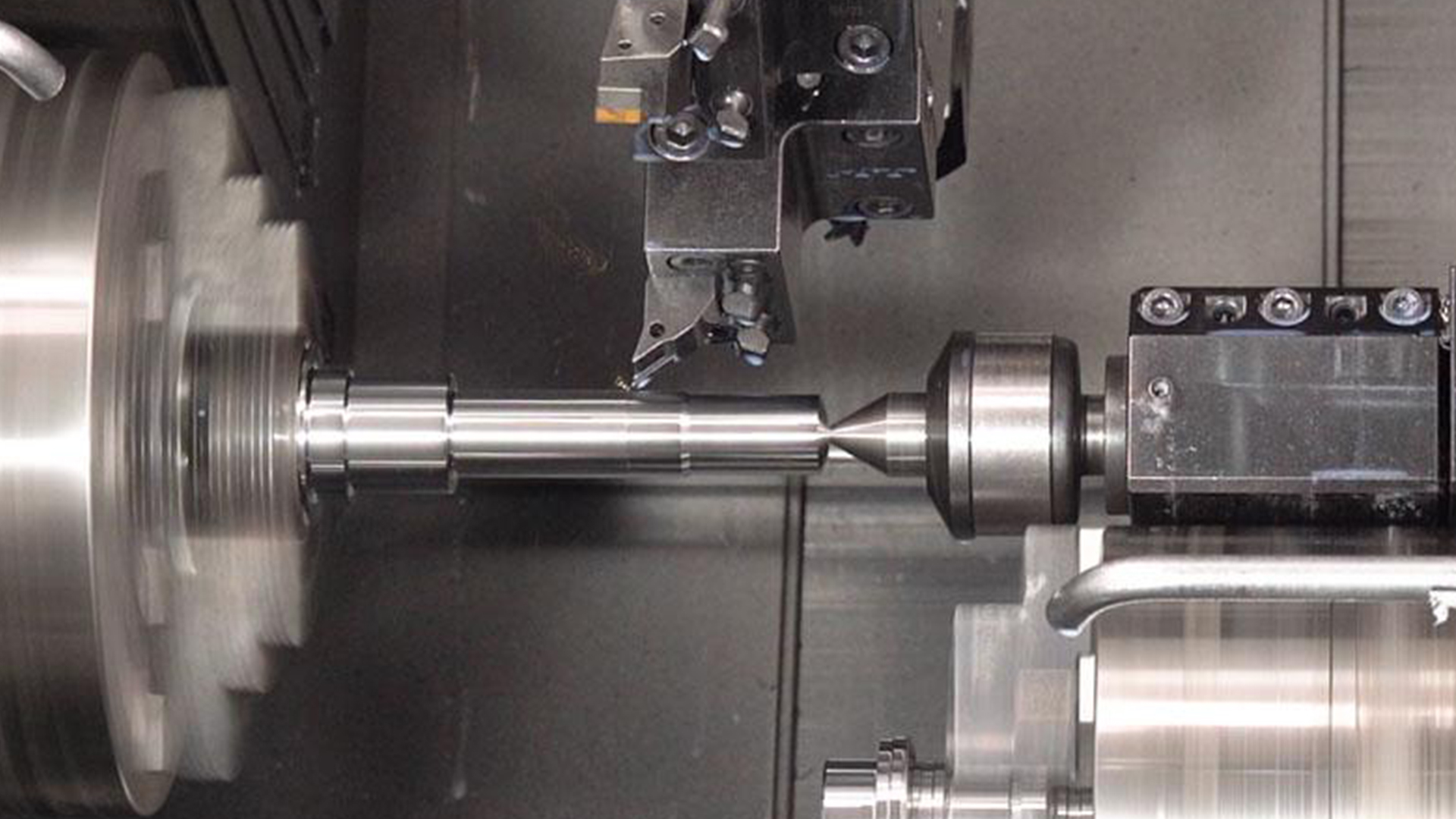

- Vibration Reduction: CMZ lathes feature main and sub-spindles mounted on roller bearings, minimizing vibration and allowing turning away from the chuck face.

- Finishing: The tailstock is used for the finish pass, turning between the chuck and tailstock on the sub-spindle.

- Unloading: The completed part is transferred to an unloading table for easy operator access. The Gantry Loader is ideal for automating this production process.