Southend-based Rega Research has applied engineering as the basis for the design and manufacture of its home audio systems for almost 50 years. Employing engineering to produce the best music for its customers has led to innovative designs that are both aesthetically pleasing and produce the highest sound quality. This combination has created a loyal customer base, with the past two years seeing significant sales growth, which resulted in its latest investment in an XYZ 750 LR vertical machining centre.

Rega Research was founded by Roy Gandy, who struggled to find an audio system that met his expectations. He was advised to ‘build his own’ if he couldn’t find what he wanted and the rest is history. Using his engineering skills gained in the automotive sector Roy’s re-engineering journey to create new concepts in audio began. The company now designs and assembles a full range of home audio equipment including turntables, amplifiers, phono stages, CD players, tonearms, cartridges and speakers. Production stands at over 5000 turntables every month made up of 3000 units/month of its entry-level P1 turntable, over 1000/month of its mid-range P3 turntable and 70 units/month of its range topping P10 turntable, which retails at around £5000. Add these to its other products and production tops 10,000 units/month.

There is a subtle difference between music lovers and Hi-Fi enthusiasts and Rega’s products appeal to the former: “Our customers love music, many would go to concerts daily if possible, so we strive to deliver a level of quality that can replicate that experience for them,” says Ky Gandy, Supplier Co-ordinator, Rega Research. The blend of high quality, design and value for money has seen Rega grow from 130 employees at the start of 2020, with a turnover of £13m to a £20m turnover and 180 employees at the end of 2021.

This significant growth added pressure to Rega’s Toolroom, which was populated with manual machines to produce assembly jigs and test rigs, as well as some prototype machining. A move to CNC had been on the cards for many years, but had been put off for several reasons, particularly a lack of space. A re-organisation combined by the increase workload allowed the purchase of an XYZ 750 LR VMC to go ahead. The machine will be used on a variety of materials from aluminium, High Pressure Laminate through to MDF, so Rega opted for the 12,000 revs/min model and a 4th axis with 24 position arm-type toolchanger option.

“We had been looking at introducing CNC to our toolroom for several years, we did our research and while the machine was important, ongoing support and service was a priority. This resulted in a shortlist of one, XYZ Machine Tools. During our search, we kept coming back to XYZ and in the end, it became a straightforward choice due to the confidence we had in their ability to support us with technical help and after-sales. We also received glowing reviews from our existing component suppliers. Another factor that made the decision easier was that during the quotation process they didn’t try to upsell to us, we indicated an interest in their HD machines, but they did the right thing and sold us the machine we needed, not what we thought we wanted.”

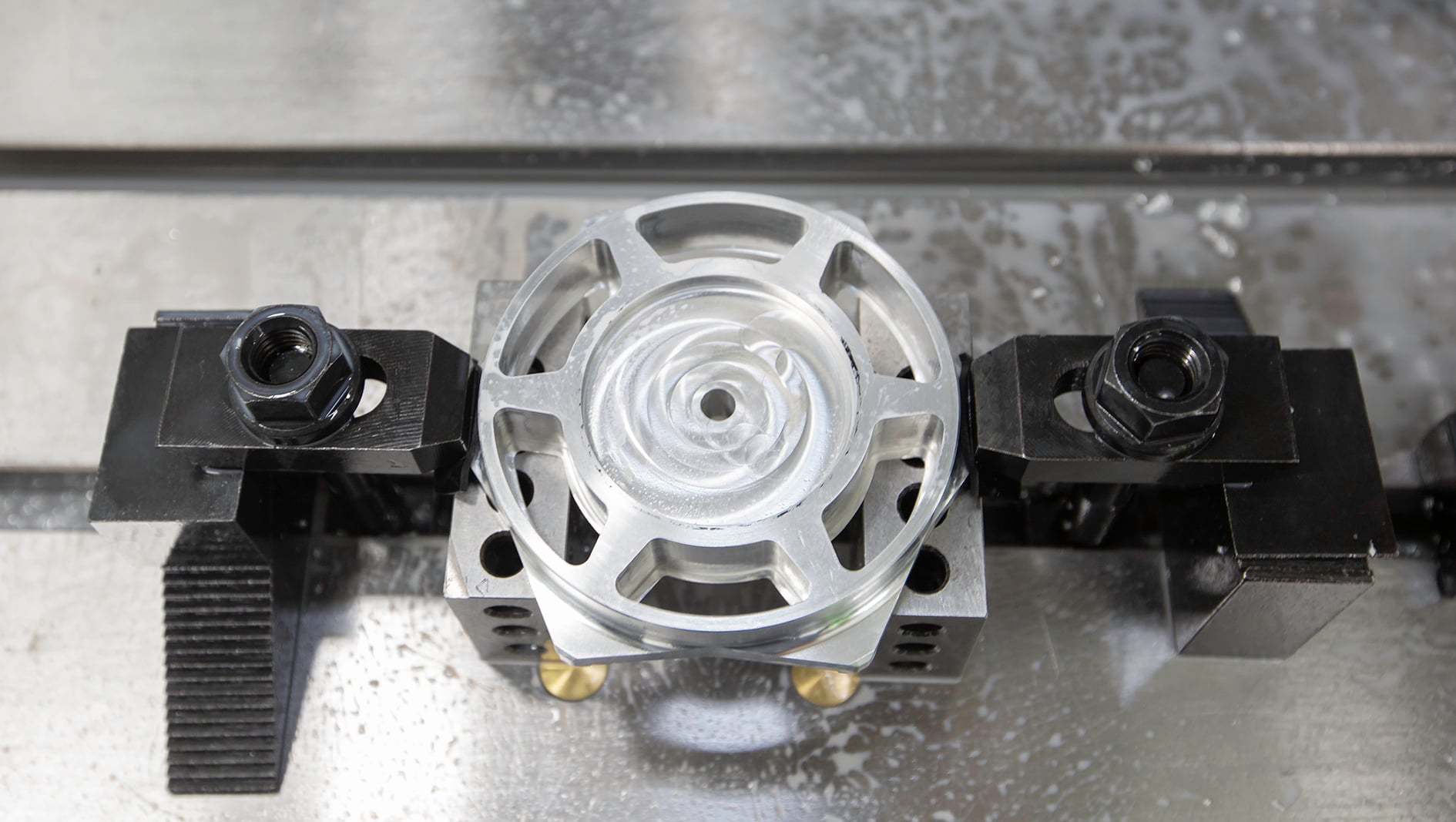

Throughout the pandemic, focus was on delivering products to meet demand, so product releases were put on hold. Now, with a degree of normality returning, new products are on the horizon with new turntables and amplifiers due to be launched in 2022. This will see an increased workload for the XYZ 750 LR in terms of machining development parts and the testing fixtures that will also be needed. Having the machine will enable Rega to respond quickly to change and to meet the increased demand from its assembly department, where demand for fixturing continues to grow. There are no plans for the XYZ 750 LR to be used for production work, but it is filling a need for re-working existing stock components that may need rectifying or adjusting. A recent example was a batch of plinths that were found to be out of concentricity tolerance on two bores. “The obvious solution was to return the entire batch to our supplier, but that isn’t the Rega way of doing things,” says Ky Gandy. “We respect our suppliers and accept that occasionally errors arise, so we decided to rectify the parts ourselves. We used the XYZ 750 LR to manufacture a fixture, which was then able rework the parts to within microns. Something that saved time and money thanks to the efficiency of the machine and the input from Dan Ware, who joined us specifically to run the XYZ machine.”