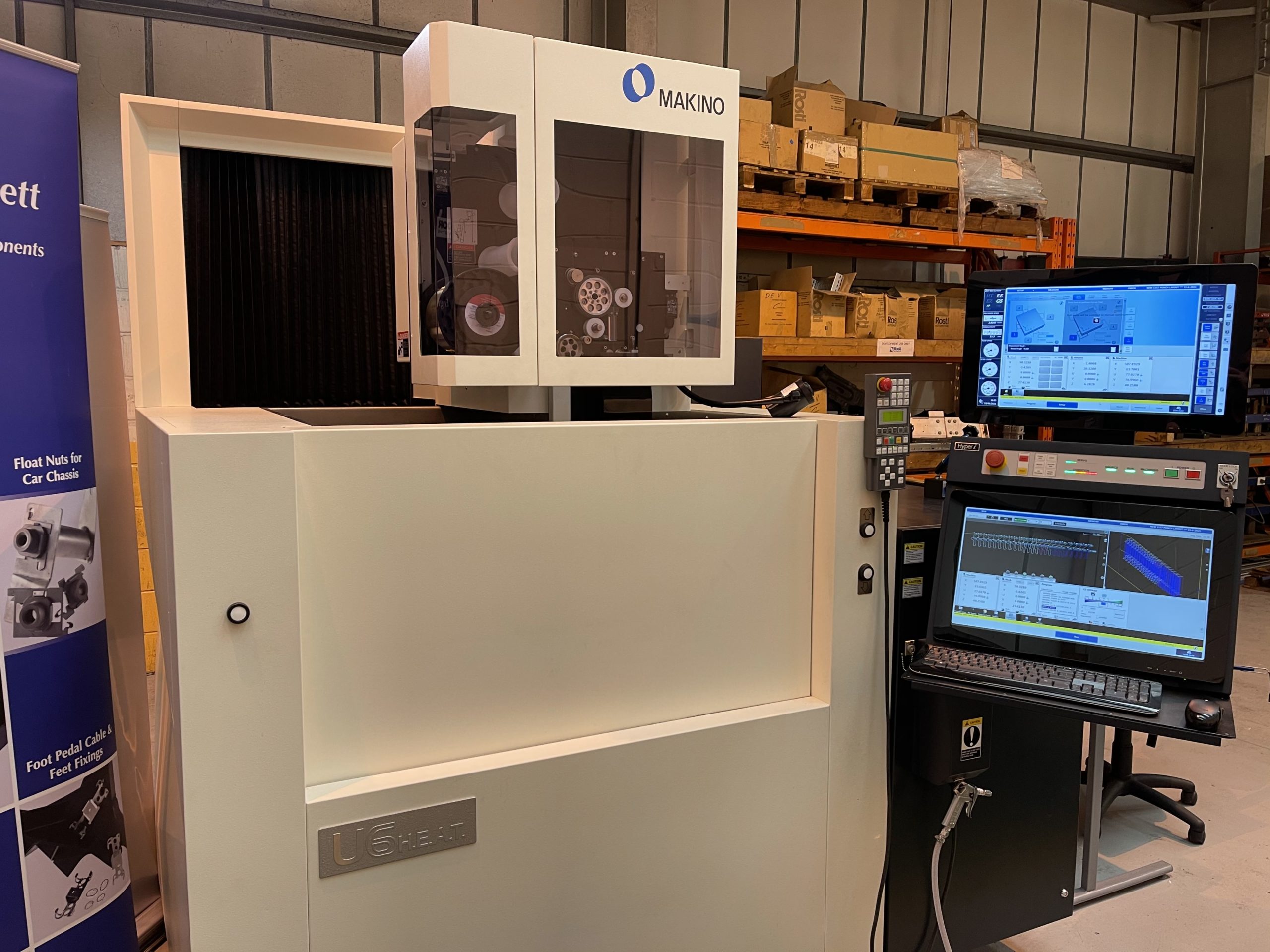

Formed from two separate companies almost two years ago, Xandor Automotive Canning Brett has a global manufacturing presence supported by five production sites in the UK with additional sites in China, Germany and the Czech Republic. At the Pontardawe facility, the company manufactures injection mould parts, metal fixings, pressings and brackets primarily for the automotive industry. To support the company’s growth, it has just purchased a Makino U6 HEAT wire EDM machine from NCMT.

The company is currently looking to take advantage of the current economic climate and investigate new markets, and this is one of the reasons that Swansea based Xandor has invested in the Makino U6 HEAT machine. Commenting upon the existing portfolio of products, Ceirion Jones from Xandor says: “We probably have more than 200 different product lines with between five and seven million parts made every month that are supplied to over 70 different customers. This makes the metal pressing side of our business very important to us. We have an on-site toolroom that services the business, but we are also looking to manufacture tooling. The better the technology and equipment we have, the more competitive we become.”

The U6 HEAT can maintain positional accuracy of +/-1micron whilst the four-sided 910 by 710mm table offers an X, Y and Z-axis of 650 by 450 by 420mm with +/-75mm in the U and V axes.

“We had been looking at a wire EDM machine for several months and we selected the Makino as this investment is not just to help our production, but also what it can offer as a sales service for external customers. This strengthens our business and helps us to grow.”

The South Wales company manufactures components such as front and rear door modules, engine covers, posts and caps, compression limiters, battery box traps, compression rings and more for leading OEMs in the auto sector, so precision toolmaking and subsequent pressings are critical.

Ioan Turner, the Production Shift Manager at Xander comments: “We are not new to EDM, we’ve had an EDM machine on site for over 20 years as it is a critical process for our business. We looked into the market, met up with Scott from NCMT and the U6 HEAT machine stood head and shoulders above every other EDM machine.”

“Some of our press tools are 250 tonnes, so accuracy is critical for us. Buying a machine that can withhold tight tolerances is a major factor for us. The maintenance and running of the machine are key factors that sold the machine to us. Maintaining an older type of machine can be a lengthy process and sometimes a machine can be down for several hours just to change the crystals or the wire guides. With the Makino, it is just a quick release system where we can flick the tools out and the machine is up and running,” says Ioan.

“We are now more efficient and are using less wire than before. This machine has to be capable of running 24 hours a day, running punches and dies and keeping the spare parts out on the shop floor, so we can keep production running.” This is a credit to new low wire consumption technologies whereby Makino has worked to reduce the single largest expense of operating a wire EDM machine. The U6 HEAT contains a ‘machining conditions’ library that has been developed to provide an optimal mix of speed, accuracy, surface finish and low wire consumption for both sealed and poor flush applications. The machine utilises larger capacity independent dual flushing pumps and it harnesses this additional horsepower to deliver higher pressure and volume of flushing to machining to reduce rough-cut cycle times.

Makino’s Hyper i control provides the U6 HEAT with intuitive and familiar touch Pinch/Swipe/Drag operations similar to smartphones, so the operator is provided with an effective view of the control with the large 24” HD touch-screen display that is enhanced with a mouse, keyboard and full-function advanced Handbox. Referring to the CNC control system, Ioan continues: “Having an old machine running for over 20 years, you tend to get stuck in a rut, but the new machine technology is fantastic, and it is a learning curve for the operators. The performance and the speed this machine can run at; is way beyond any other machines we have had. The service and support from NCMT has been fantastic and they are always at the end of the phone. If we need them, they will be on-site the very next day.”