Following its world premiere at EMO, VOLLMER will give its UK debut to the new VGrind 360S grinding machine. For the complete machining of carbide tools, the Vgrind 360S on Stand 550 in Hall 20 will appear alongside the CHX/HS and the VOLLMER Loroch Powerstar machines for sharpening circular saw blades.

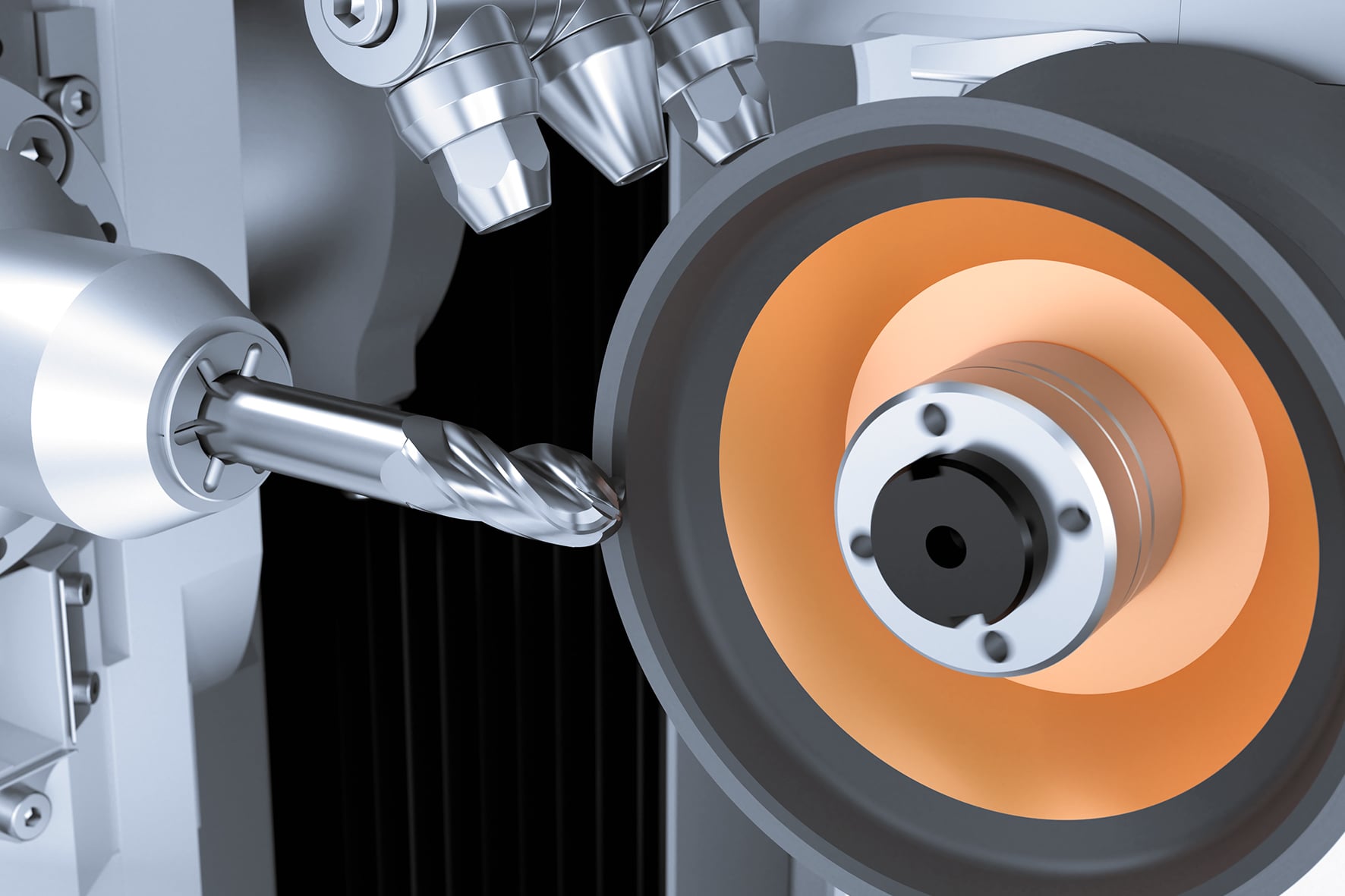

The impressive new VGrind 360S can be used to machine carbide tools with a diameter up to 25.4mm and depending on the machine kinematics and the equipping of the grinding wheel packages, it can even be used for tools up to 150mm diameter.

With more precision and power thanks to its linear induction motor and linear slides, the VGrind 360S reduces maintenance costs by utilising magnets. Furthermore, the kinematics deliver improved precision and higher surface quality on the cutting tool.

For simple and intuitive operation, VOLLMER has created an ergonomic platform whereby users can operate the control panel comfortably whilst having full visibility of the work envelope. Operation via the keyboard or touchscreen allows for precise machining of the tool and the multi-function handwheel ensures even more flexibility as it can be freely positioned on the enclosure.

The vertical double-spindle concept, now features an oriented spindle-stop for the first time. Known as spindle indexing, this always stops the spindle at a specific position and the result is a reduction of axial run-out errors and concentricity issues whilst offsetting wear in the HSK holding system. Another new feature is a heat plate exchanger to efficiently cool motors and spindles, which in turn leads to increased thermal stability.

The VGrind 360S incorporates VOLLMER’s operating concept and can be operated unmanned around the clock thanks to automation features such as a pallet magazine, free-arm robot or chain magazine.