Prismatic machining accounts for a majority of throughput at the Mildenhall factory of CTPE, a subcontractor that produces complex, high-precision components for the defence and electronics sectors. However, productivity on the turning side of the business received a significant boost in mid-2022, when the company bought a Miyano twin-spindle turning centre with twin Y-axis turrets and live tooling.

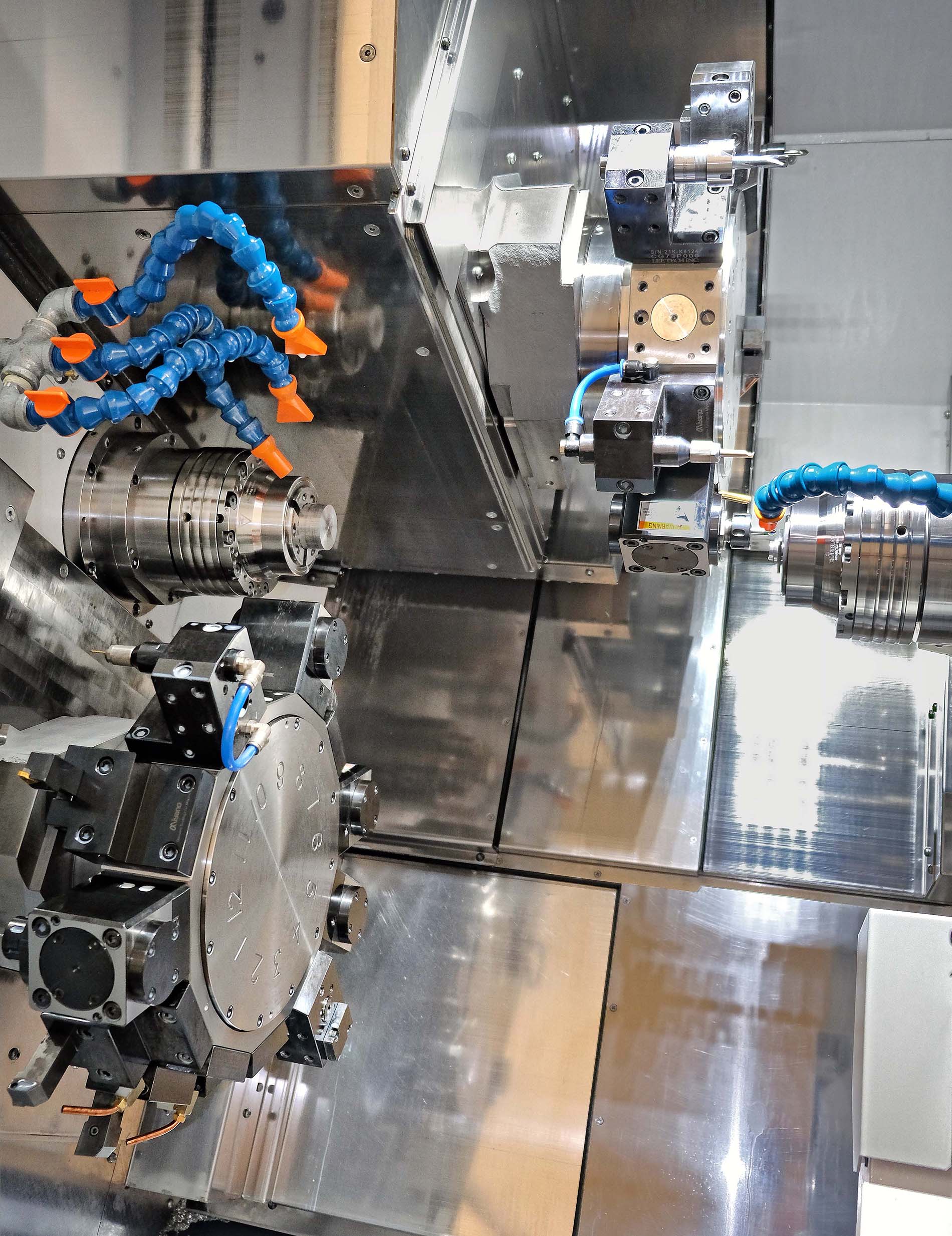

Supplied by Citizen Machinery UK, the 10-axis ANX-42SYY lathe is fitted with a FANUC 31i 15-inch touch-screen control incorporating a new HMI. It also features the company’s superimposed machining, whereby three tools can be in cut at the same time thanks to X-axis movement of the sub-spindle. Three-axis simultaneous interpolation and double Y-axis cutting are also enabled.

Advantage is regularly taken of the machine’s other stand-out feature, LFV chipbreaking software in the control’s operating system. The function is independent of the programmed cutting cycle, apart from it being switched on by G-code when expedient to break up stringy swarf, which is particularly problematic when taking finishing cuts. LFV may similarly be switched off when it is not needed.

CTPE’s operations director Alex Taylor said: “We saw LFV demonstrated on the Citizen stand at MACH 2022. The function is extremely useful when machining aluminium, which constitutes most of our work and is even more effective on plastics, which accounts for about 25% of our throughput.

“We struggle with bird’s nesting when internally boring both materials, as the swarf tends to leave marks that affect the bore diameter and in the case of plastic can cause burning. LFV avoids these problems, so machine stoppage for swarf clearance is no longer needed, increasing productivity and enabling reliable unattended operation overnight.”

One example of the software’s effectiveness involves a defence electronics part regularly produced from aluminium bar. After experimenting with dwells and pecking macros to improve chipbreaking, Mr Taylor was only able to run 50 components before having to stop the machine to clear swarf. That was therefore the maximum number that could be produced lights-out. The situation was acceptable when the customer was ordering batches of 250, but as volumes grew steadily to 2,000 per order, it was denting the profitability of the contract.

The problem has been resolved by having the chipbreaking software switching in and out on the Miyano during difficult parts of the cycle, so the machine can confidently be left to run throughout the night. Moreover, the cycle time has fallen from three minutes on a twin-spindle, single-turret, fixed-head lathe, or two minutes when the work was put onto a sliding-head bar auto, to just one minute and 40 seconds on the Miyano. So around 400 finished parts are waiting for staff when they return in the morning.

What the company wanted was an increased number of tools so there would be more likelihood of the next job starting as soon as a new program was loaded. The 12 live tool stations in each of the two Miyano turrets provide that flexibility with the ability to leave more pre-set tools in the machine, speeding up changeover and maximising spindle uptime.

Mr Taylor concluded: “The Miyano is the most solidly built, accurate machine we have ever bought. Lathes tend to suffer more than machining centres from thermal movement when they are switched on in the morning. They are typically 30 microns out for about 15 minutes while they warm up, but not the ANX.

“After we power it up, it immediately starts producing a part we were machining the previous afternoon to the same single-figure-micron accuracy, without any offsets being entered. Some tolerances we hold are down to ± 5 microns, which we have no trouble achieving.”