🎧The right tool for the job

The grinding specialist Kellenberger, part of the Hardinge Group, has developed a groundbreaking innovation to simplify the automation of grinding workpieces of varying lengths for a tool manufacturer.

For a considerable time, users have been interested not only in machines but also in machining solutions. Regarding these solutions, the machine manufacturer is responsible for the entire process, covering all upstream and downstream operations. The continual advancement of automation in production processes also presents challenges to the flexibility of machine tools. This innovation can be explored through UK specialists DF Precision Machinery.

At the Kellenberger base in Goldach, Switzerland, the emphasis is on customer-specific system solutions. There, highly integrated cylindrical grinding systems for large-scale production are fitted with automatic loading, measuring devices, and other supplementary operations as required. Each year, a diverse range of turnkey solutions are delivered to customers, including automotive manufacturers and various suppliers.

At the Kellenberger production site in Goldach, the ‘Customer-Specific Special Construction’ department develops solutions that are especially challenging and not yet available on the market.

A well-known tool manufacturer was seeking a solution for the automated grinding of workpieces such as drills and tool holders. The challenge in machining lies in the fact that the parts have varying lengths. This necessitates that the clamping force be adjusted manually for the required length compensation during grinding. Automated machining is therefore not feasible in this context.

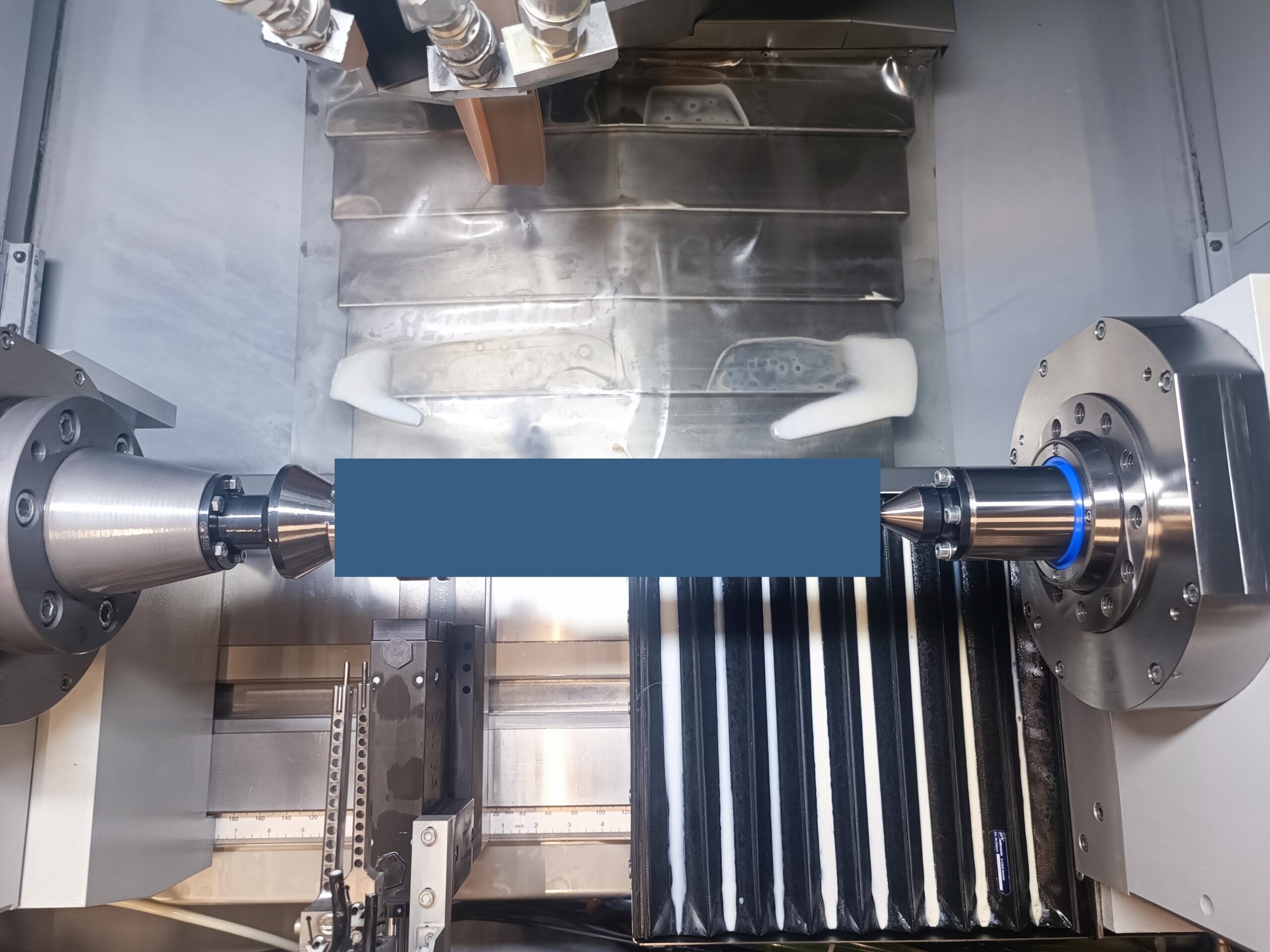

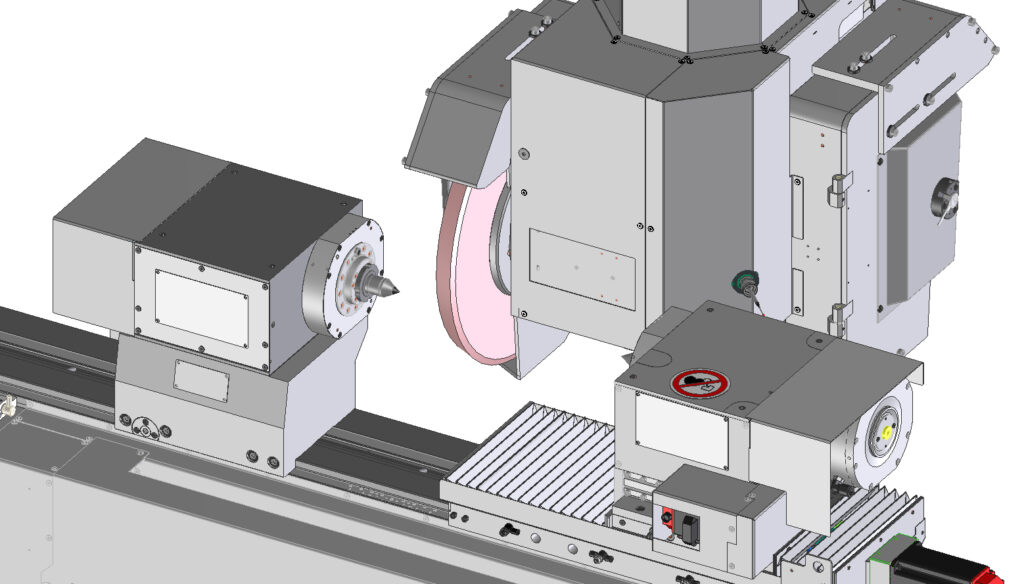

The designers in Goldach met the challenge and rose above the competition. They developed a positioning axis (Z2 axis) that ensures automatic length compensation by a robot or gantry loader during the fully automatic loading.

The Z2-axis is mounted on the Z-axis and moves accordingly. The automatic zero-point shift is implemented using a longitudinal pushbutton (KEL-Pos). Dressing is not permitted on the Z2-axis. The grinding dressers are mounted on the Z-axis.

Workpieces with up to 250mm diameters and length compensation ranging from 50 to 300mm can be machined. Non-circular parts can also be ground and can be centred fully automatically.

In summary, the machine features a 250mm hub with a minimum centre height of 250mm and an axial force ranging from 50 to 1200n. The load capacity for live spindle grinding is 200Nm for a maximum load of up to 150kg. When using a synchronous tailstock (available as an optional feature), no chuck is needed due to the friction drive. An in-process measuring control covers a diameter range of 25mm. Manual retooling is no longer required.

The Z2 axis was developed for the universal internal and external cylindrical grinding machines of the K100 and K1000 series with Fanuc control. The obvious question is: can the Z2 axis be retrofitted onto such machines? Patrick Gähler, Design Engineer at Kellenberger, answered: “Retrofitting is impossible because the function of the Z2 axis must be incorporated in the design of the machine beforehand.” In the showroom at Kellenberger in St. Gallen, interested customers will have the opportunity to see a KELLENBERGER K100 with Z2 axis, on which tests can also be carried out.