MTDCNC recently visited YMT Technologies in Yeovil where Paul Jones spoke with Steve Wright from Heidenhain to discuss the latest innovation, the company’s StateMonitor PC-based tool.

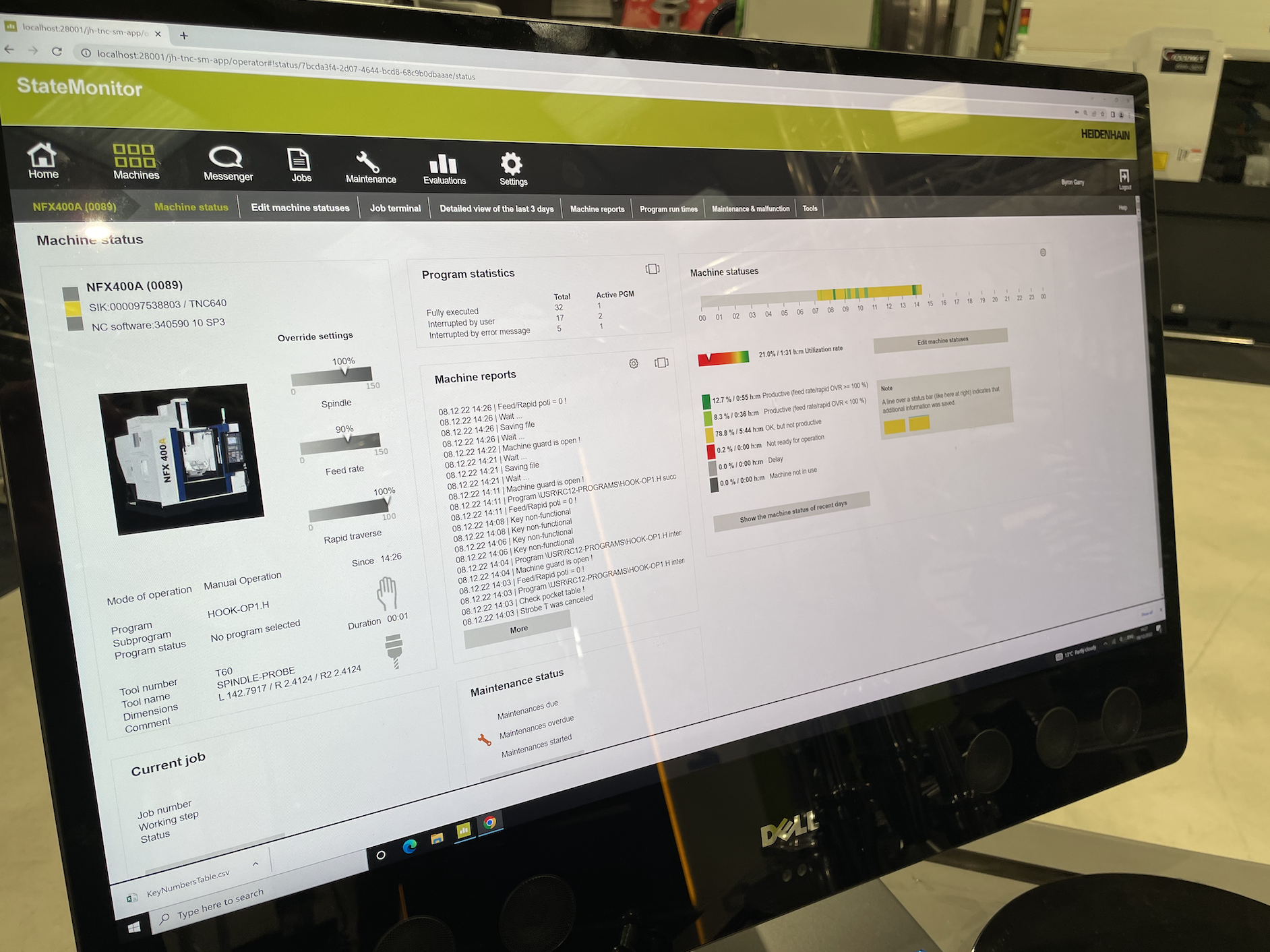

Telling MTDCNC about the new system, Steve said: “The StateMonitor system is a PC-based tool that is a machine data acquisition system for monitoring the productivity of all of your machine tools.” Identifying why a company would require such a system, Steve adds: “The reason you need this system when your machine tools aren’t cutting metal, they’re not making you any money – StateMonitor will manage that situation.”

Steve continues: “There are a lot of benefits with the system. Machine downtime issues can range from component loading and unloading, probing or inspection during the cycle or an alarm situation – all of this data can be collected on the StateMonitor software. When it comes to incorporating this system into machine tools, the cost savings can be incredible, firstly when you realise how much time a machine tool spends being idle.”

Considering a specific example, MTDCNC’s Paul Jones states: “If you look at a company that has five machine tools and each machine has 30 minutes of undetected downtime per day, that is a total of 2.5 hours of lost machining time every day. If each of these machines ran at £70 per hour, the cost would be £175 per day. If you multiply this by 260 days which is the typical equivalent of one year of operation, a company could be haemorrhaging £45,000 per year in lost machining hours.”

Commenting on this, Steve says: “The savings can be quite remarkable and implementation can be very easy. We can load the software to a PC and as long as the machines are networked, they will talk to the software and we can connect machines in 5 to 10 minutes.”

Commenting on this, Steve says: “The savings can be quite remarkable and implementation can be very easy. We can load the software to a PC and as long as the machines are networked, they will talk to the software and we can connect machines in 5 to 10 minutes.”

Looking at some of the primary features, Steve continues: “The primary objective is to monitor all of your machines. When we do that, we can look at the production side of the machine, such as the setup, loading and unloading and how much time is spent undertaking each aspect. We can also look at the programme to see if there are too many dwells in the programme, or the tool change sequences in the programme – and eliminate and optimise that time. We can even monitor the feed rate override pods for spindle and the feed rate override, so we know if a machine is not as productive as it can be, as we can pick that up on the StateMonitor.”

“In addition, we can monitor the tooling and how the tooling is being used, how frequently tools are being used and which tools are being used the most. This allows businesses to look at how tooling is being used and if it can be used more efficiently. We also monitor the alarms on the machines and the alarm fault condition to monitor any maintenance requirements on the machine. In StateMonitor, you can pick all of these things up to increase the productivity of your machine.”

Referring to access to this information, Steve continues: “Customers can have full remote access from an iPad, smartphone or PC. With regards to notifications, there is a Messenger notification built-in to the StateMonitor software, so the system can notify the right person for the right reason as to why the machine has stopped. For machine licensing, we can either sell a single machine license or a single license that covers up to 30 machines.”

“Typically a machine is only running and efficient 60% of the time and any increase on this can have huge cost benefits. We have examples that demonstrate huge savings. With one customer, they identified that the feed rate override pot was being overridden at certain shift times. They also identified that the loading of components was taking too long. The company addressed both issues and increased the productivity rate from 60 to 80% on the machine tool,” concludes Steve.