🎧The future is bright for Bronte

Arecent investment in a large-capacity, heavy-duty vertical machining centre equipped with a powerful gearbox-driven BT50 spindle is proving transformative for Bronte Precision Engineering Ltd., a precision subcontract specialist based in Bradford, West Yorkshire.

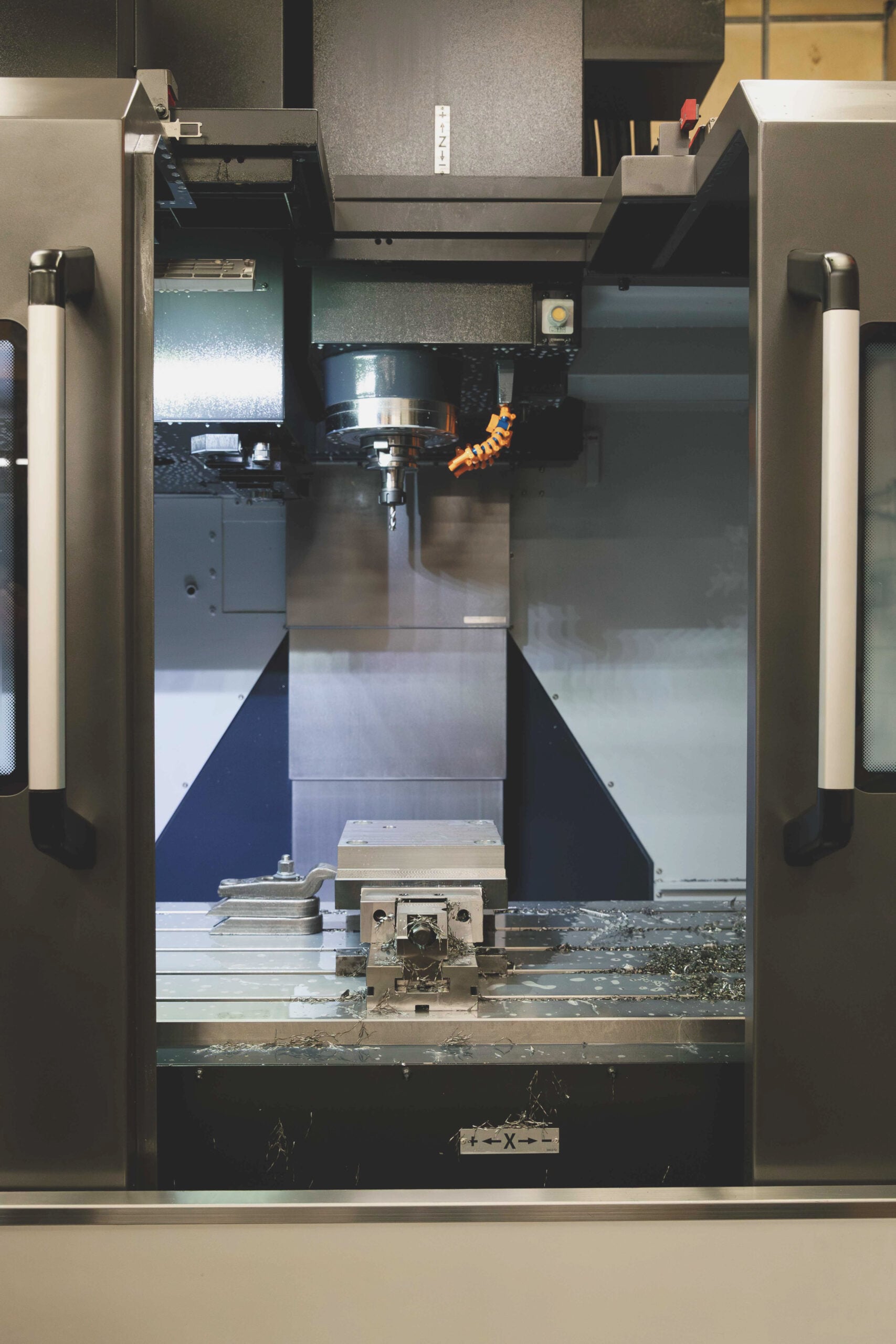

The arrival of DN Solutions’ Mynx 6500/50 II in July 2025 has significantly increased Bronte’s machining capacity, improving productivity and optimising processes within weeks.

Mills CNC, the exclusive UK and Ireland distributor of DN Solutions and Zayer machine tools, supplied the new heavy-duty 3-axis vertical machining centre.

The box guideway Mynx 6500/50 II was installed at the company’s 16,000sq ft Bradford facility in July 2025, replacing an older Daewoo Mynx 540 BT40 machining centre originally supplied by Mills CNC in 2004. Equipped with the latest FANUC 0iMP control and a 6,000rpm BT50 high-torque spindle, the machine has been machining high-precision complex components.

Strategic Acquisition and Growth

Bronte was acquired in November 2024 by Huddersfield-based B&B Engineering Ltd., a specialist precision engineering subcontractor renowned for high-quality CNC machining and HVOF coating services.

The acquisition was led by entrepreneur and director Steven Haigh, who explains: “We acquired Bronte because I could see definite synergies and opportunity for exponential growth. By combining our staff’s experience and technical resources, we could increase manufacturing capacity whilst improving flexibility and responsiveness.”

Following the acquisition, a comprehensive audit identified process inefficiencies and production bottlenecks, including the company’s Daewoo Mynx 540 – a 20-year-old 3-axis vertical machining centre.

The Case for Investment

Bronte’s Mynx 540, acquired in 2004, had been machining complex, high-precision parts for customers in oil and gas, power generation, marine, rail and EV sectors for two decades.

Whilst rigidly designed with box guideway construction, the Mynx 540’s 15kW BT40 belt-driven spindle was not ideal for fast, efficient machining of hard materials such as Inconel, Monel, cast iron and stainless steels.

Steven Haigh explains: “The machine was holding us back. Part cycle times were overly long, and processes had to accommodate the machine’s limitations. To improve performance, we needed a new, high-performance machining centre.”

Bronte compiled a comprehensive specification requiring a rigid machine with box guideway construction, powerful high-torque BT 50 spindle with through-spindle-coolant, large capacity worktable, generous automatic tool changer, probing systems and latest FANUC control. The company selected the Mynx 6500/50 II based on specification, cost, availability and Mills’ comprehensive services.

Performance and Results

Since installation, the Mynx 6500/50 II has been machining valve-type components for subsea applications from Inconel castings. These parts are approximately 400 by 300mm, involve intensive roughing and finishing operations, and demand tight tolerances and stringent surface finishes. Part processing times are up to 50% faster than with the Mynx 540, fully justifying the investment.

Bronte’s new Mynx 6500/50 II features a high-torque, gearbox-driven BT 50 spindle, 30-tool servo-driven tool changer with 2.5second tool-to-tool changeover, and 1400mm x 670mm worktable with 1300kg maximum load. The machine was supplied with FANUC 0iMP control, 20bar through-spindle-coolant and Renishaw OMP 600 and OTS probing systems.

Steven Haigh comments: “The Mynx 6500/50 II is a powerful, accurate and flexible machining centre that has proved its worth within weeks. The machine’s rigidity and powerful BT 50 spindle has enabled us to significantly improve productivity. The ability to ramp up speeds and feeds and take more aggressive depths of cut has dramatically improved part cycle times.”